What is Leeb Hardness Tester?

An instrument for testing and measuring the hardness of metal materials is the Leeb Hardness Tester. It was created using cutting-edge microelectronics technology and the Leeb Hardness Test. It is especially useful for evaluating the hardness of workpieces that are huge, heavy, difficult for disassembly, have a small area, have multiple orientations, or have specific features. It may be used to test metal materials with a wide range of hardness.

Why use the Leeb hardness tester?

One of the often employed metrics to evaluate the mechanical characteristics of metals is hardness. Hardness testing is primarily used to assess a material's compatibility or the impact of a specific hardening or softening treatment on a material for the use for which it is designed.

For the material being tested, the hardness measures how well different physical properties—including elasticity, plasticity, strength, toughness, and wear resistance—perform collectively when subjected to a certain indenter and test force. Because a hardness test can reveal a metal's composition The hardness test is often used in the examination of metal characteristics, monitoring of heat treatment process quality. And creation of novel materials due to the variation in performance under diverse chemical composition, organizational structure, and heat treatment process.

The principle of Leeb hardness tester

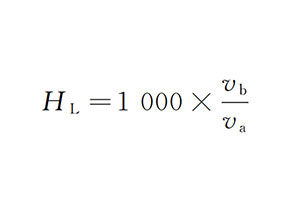

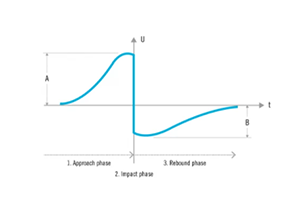

An impact body of a specific mass contacts the surface of the sample at a specific rate while acting under the influence of elastic force. The hardness of the sample is determined by dividing the impact rate by the impact body's rate of rebound at a distance of 1 mm from the surface of the sample. Figured out as follows:

formula

schematic diagram

Products

The following is a list of several Linshang Technology Leeb hardness tester.

LS251D Leeb Hardness Tester

Separate design, digital probe technology

LS252DC Leeb Hardness Tester

Integrate design, small size

LS252C Leeb Hardness Tester

Integrate design, small size

How to choose the Leeb hardness tester?

Before utilizing the Leeb hardness tester, attention should be made to choose an appropriate impact device since the quality, shape, and thickness of the tested material will affect the hardness measurement.

D type: Usually, common metal parts may be measured in a standard arrangement.

DC type:Suitable for determining the hardness of metal for thin or inner holes

DL type: Suitable for determining the metal hardness of small, precise grooves, tooth surfaces, or the inner control's bottom

C type: Suitable for assessing the hardness of tiny, thin metals or surface-hardened layers.

G type: Suitable for determining the hardness of materials made of steel, cast iron, and non-ferrous metals

S type: Suitable for assessing the toughness of non-metallic materials with a very high hardness

D+15 type: Suitable for determining how hard a metal surface, groove, or concave surface is.

You can refer to this page“Linshang Leeb Hardness Tester Selection and FAQ” to learn what sort of Leeb hardness tester is utilized in actual applications.

Introducing LS251D Leeb Hardness Tester

This video explains how the LS251D Leeb Hardness Tester measures hardness in a variety of applications.

Introducing LS252D Leeb Hardness Tester

This video provides a detailed introduction to the features and functions of the LS252D Leeb Hardness Tester.

How to use the Leeb hardness tester

1. Loading: To guarantee that the impact body is locked, turn on the instrument, depress the loading sleeve of the probe, or push up the impact body at the bottom of the instrument with the loading rod. When loading, avoid setting the instrument on the surface of the measured object.

2. Positioning: Hold the measured item stationary while pressing the instrument probe vertically against its surface.

3. Release: To gauge the test object's hardness, press the release button on the probe's top.

4. View: The hardness value determined at that particular time is the value shown on the instrument's screen. When you push and hold the down button on the data record interface, the question "delete recorded data?" will display, allowing you to delete the data record. To select, quickly push the power button, then to confirm deletion, quickly press the down button.

5. Calibration: Short press the power button to enter the settings interface, short press the up button to select, and short press the power button again to confirm. The screen will flash and begin to measure the standard hardness block. The actual value of the standard hardness block will then be turned over by short pressing the key to adjust to the actual value.

Precautions for using the Leeb hardness tester

1.Keep the measurement object's surface level and clean, free of debris and blemishes.

2.When the measured object's mass and thickness are smaller than the required minimum mass and thickness, coupling the object to a sturdy support is required for measurement.

3.When measuring, the space between any two indentations on the material should not be less than 3mm. And the space between the center of the indentation and the edge of the object being tested shouldn't be less than 5mm. Additionally, it is best to avoid performing multiple tests at the same location.

4.It is essential to briefly push the power button to enter the configuration interface, pick the material, and then carry out the measurement operation when it is necessary to convert other hardness values.