Difference between Coatings | Coating Thickness Gauge

With the development of city, more and more steel frame systems are used to replace traditional reinforced concrete. However, we know that steel is easily corroded, so the anticorrosive and fireproof coating on the surface of these steels is particularly important. Usually we use a coating thickness gauge to check whether the anticorrosive coating on the surface of the steel is up to standard. So what's the difference in the construction of fireproof coatings and anticorrosive coatings?

1. Difference between finished product protection

It is difficult to repair the coating of fire-resistant coatings. In addition, fire-resistant coatings are more sensitive to the external environment. Intumescent fire-resistant coatings contain a large amount of substances used for expansion and foaming. These substances easily react with water and chemicals, affecting the coating performance and even cause rework. Thick fire-resistant coatings contain light-weight fillers such as perlite and vermiculite. The coating surface is relatively soft, which is vulnerable to mechanical damage. Some light-colored filler also easily react with water or chemicals. The best way is to avoid repairing the coating as much as possible. The protective measures for finished components need to be done well, so the protective measures for the finished components are more stringent, including protection of the components during hoisting, transportation and storage. Anti-corrosive coatings also need to protect the finished products of finished components, but fire-resistant coatings are stricter than it. Therefore, the thickness of these two coatings is generally measured with a coating thickness gauge after completion.

The dry film thickness is thick measured by coating thickness gauge. Except for a few low-temperature-resistant fire-resistant coatings, the rest will easily cause cracking at low temperatures. Certain antifreeze measures need to be done; anticorrosive coatings generally do not crack at low temperatures, so antifreeze protection measures are not required.

2. Differences between construction sites

The finished product protection of fire-resistant coating is very important. In addition to protect the finished product as far as possible, there is another way to carry out the construction at the construction site or the steel structure workshop near the construction site as much as possible to reduce the transportation route Anti-corrosive coatings can be applied in the workshop . As mentioned earlier, fire-resistant coatings are very afraid of water and chemicals, so certain protective measures need to be taken before spraying the top coat.

The different purposes of fireproof coatings and anticorrosive coatings determine their different formulations. The different formulations determine their different constructions. Steel structure coating designers, managers and construction personnel can better carry out the coating design and coating construction of fireproof coatings.

3. Importance of coating thickness gauge

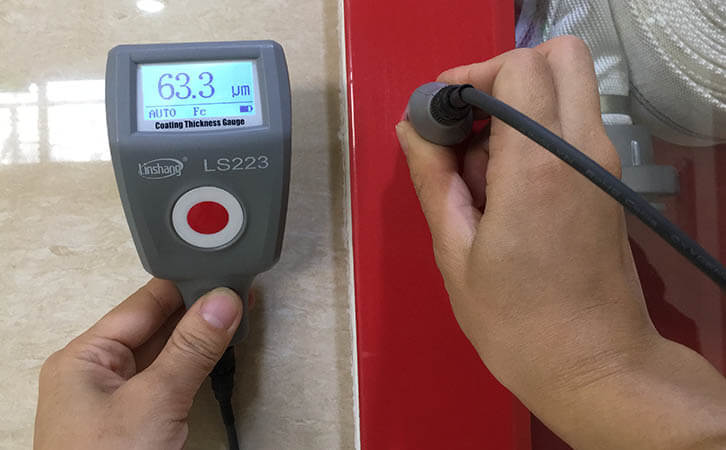

Everyone should know that the coating thickness gaugehas many functions and can test many products. It is an indispensable instrument now. The metal coating thickness gauge has become an important tool for measuring the surface thickness of objects in the processing industry. Through inspection, you can determine whether the product is qualified, or determine the production parameters to avoid material waste.

The coating thickness gauge makes the coating thickness measurement faster and more accurate, which greatly improves the production efficiency and construction quality. Therefore, it is regarded as one of the most important tools for measuring the quality of finished products in the industry. The coating thickness gauge plays a role that cannot be ignored in production. Therefore, we can use the LS223 coating thickness gauge to measure the thickness of the paint coating when the steel structure coating is applied, so as to improve our work efficiency.

- High precision coating thickness gauge for used car

- Automotive paint protection films coating thickness gauge

- Plating Thickness Measuring Instrument for Detecting Anti-corrosion Coating

- Linshang LS220, LS191, LS160A– Necessary for Car Cover Inspection

- Coating Thickness Gauge for Second Hand Vehicle

- Zero Adjustment Step of Coating Thickness Gauge