Stainless Steel Gloss Checker

Stainless steel are widely used in home appliance panels, surface decoration and other industries due to the superior surface gloss. Gloss means reflectivity of light on a surface. It is an important indicator to measure the quality of stainless steel products. There are many factors affecting the surface gloss in the production of stainless steel products. For example, the surface roughness of the raw materials in the production process, the rolling process, the leveling process, the surface roughness control, etc. It is necessary to quantify the influence of various process factors on the surface gloss by taking multiple measurements of the stainless steel gloss checker. And finally we can determine the way to improve the gloss of stainless steel in production and take measures to control the surface gloss.

1. Gloss meter working principle

The Gloss checker is an instrument for measuring the gloss of a material's surface. It uses black glass as a 100 gloss standard board to measure the gloss of other materials. According to the surface glossiness of the material, the material can be divided into high gloss, medium gloss and low gloss. We look rough in the visual sense and the materials with weaker ability to reflect light such as paper and wood belong to low gloss materials. And the specular surface and metal materials are usually high gloss materials. Common stainless steel materials are also highly glossy, so a large range of stainless steel gloss checkers are required.

2. Best gloss checker in 2021

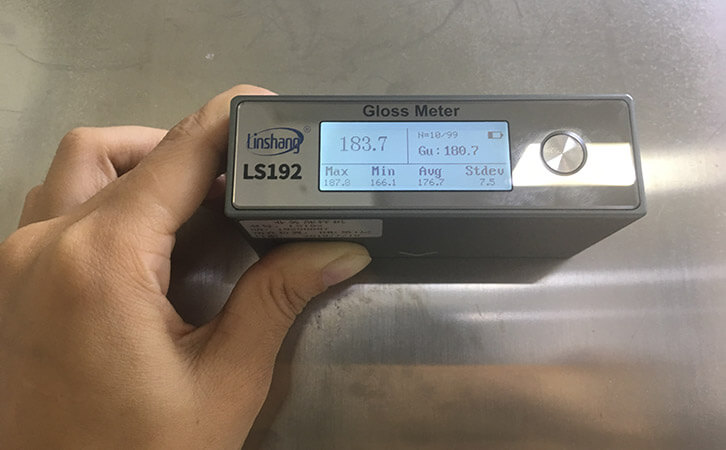

Linshang LS192 is a large-scale stainless steel gloss checker with data statistics function. In addition to testing gloss, it can also save 99 sets of test data and count its maximum, minimum, average values and standard deviation. From these data we can judge the uniformity of the surface gloss of the material. The LS192 gloss checker will be used as an example to demonstrate how we use the gloss checker to test the gloss of stainless steel elevator doors.

3. How does a gloss meter work?

First, power on the gloss checker.

After self-diagnosis and self-calibration, the instrument will enter the measurement interface.

Take off the standard board and place the gloss detector on the measured material.

Wherever we place the gloss meter, the gloss will be displayed on the screen.

As shown in the above figure, the gloss of the stainless steel gloss checker is 166.9 GU.

Press the button to record the measured gloss.

After storing a set of data, you can change the test position, measure and store multiple sets of data. After testing 10 sets of data, the results are shown in the following figure. The maximum value of the gloss values of 10 sets of stainless steel is 187.8GU and the minimum value is 166.1GU. The average value is C and the standard deviation is 176.7GU. The standard deviation is an important parameter reflecting the uniformity of gloss. The smaller the value, the closer the value of the 10 data is to the average of the data.

At present, many gloss checkers only have the function of testing data, but there is no data statistics function. Purchasing a suitable gloss checker can greatly reduce the cost of quality management. Linshang LS192 stainless steel gloss checker is a good choice.