What are the factors affecting print gloss?

Printed materials can be found everywhere in everyday life, whether it is brightly colored billboards and posters or textured gift boxes. In order to make the appearance of printed materials brighter, the production of printed materials will be varnished on its surface, so as to present a uniform color effect. However, due to factors such as the raw material of the printing paper and the printing process, the gloss of the printed surface will not achieve the desired effect. To control the quality of the printed appearance, you can use a professional print gloss meter for testing. Next, we will introduce the factors and measurement methods that affect the print gloss.

What is the gloss of printed

Gloss is an important quality test indicator for printed materials, and its gloss determines the beauty of the product. Generally speaking, printing gloss refers to the gloss of the paper after printing, the higher the gloss of the paper, the higher the gloss of the printed material, so the gloss of the paper and the gloss of the printed material are in principle unified.

Gloss different paper applications in different printed materials, high gloss paper can make printed materials bright color, full, so the general commercial packaging and decorative printing paper gloss is higher. But the gloss is too high paper, because of its reflective, not conducive to reading.

Influencing factors of print gloss

1. The impact of paper type performance

-

Paper smoothness

Smoothness of high paper, ink film leveling can produce mirror reflection; if the paper smoothness is poor, the paper surface rough, printing ink printed on, the ink film of the print is uneven, the light can only form a diffuse reflection, the print gloss will be very poor.

-

Paper gloss

Paper's own gloss and print gloss has a good correlation, the gloss of the paper is directly related to the luster of the print. Paper gloss from low to high for non-coated paper, lightweight coated paper, coated paper, waxed paper.

-

Paper ink absorption

Paper is interwoven by the fiber and the formation of capillary network structure, with a large number of pores, printing is by these pores to absorb printing ink. The better the ink absorption, the larger the gap, the printing ink loss of leveling properties will not be able to form a smooth ink film layer, resulting in a dull surface of the print.

-

Paper surface strength

Paper surface strength is not high, printing will produce hair, powder phenomenon, the ink film of the print will be uneven, for light can only produce diffuse reflection, then the gloss of the print will be reduced, or even no luster.

-

Paper surface pH

Acid paper has a delayed drying effect, while neutral or alkaline paper is conducive to printing ink drying. If the pH data on the surface of the paper is high (alkaline), printing ink drying on the paper surface is very fast, which is conducive to the formation of printed materials with high gloss.

2. The impact of printing ink

-

Ink film thinness

After the maximum absorption of the paper printing ink link material, the remaining link material is still retained in the ink film, it can be a good way to enhance the luster of the printed material. The thicker the ink film, the more linking material remains and the better it is for improving the gloss of the print. However, this may vary from paper to paper.

-

Fluidity

Printing ink fluidity is too large, the dot becomes larger, the size of the print increases, the ink layer becomes thinner, the printing gloss will be poor; printing ink fluidity is too small, the gloss is high, but the printing ink does not move easily, it will also affect the printing. So in order to get a better gloss, should control the fluidity of the printing ink, not too big and not too small.

-

Leveling

In the printing process, the printing ink leveling is good, then the gloss is good; poor leveling, easy to pull, then the gloss is poor.

3. The impact of printing pressure

Printing pressure is the key to good transfer of the print, the pressure is too large, the print increases, the gloss becomes poor; pressure is too small, the print is very fuzzy, resulting in prints without gloss. Therefore, should try to use a smaller printing pressure, relying mainly on the penetration of printing ink and oxidation film effect drying, in order to print a good glossy prints.

Print gloss measurement

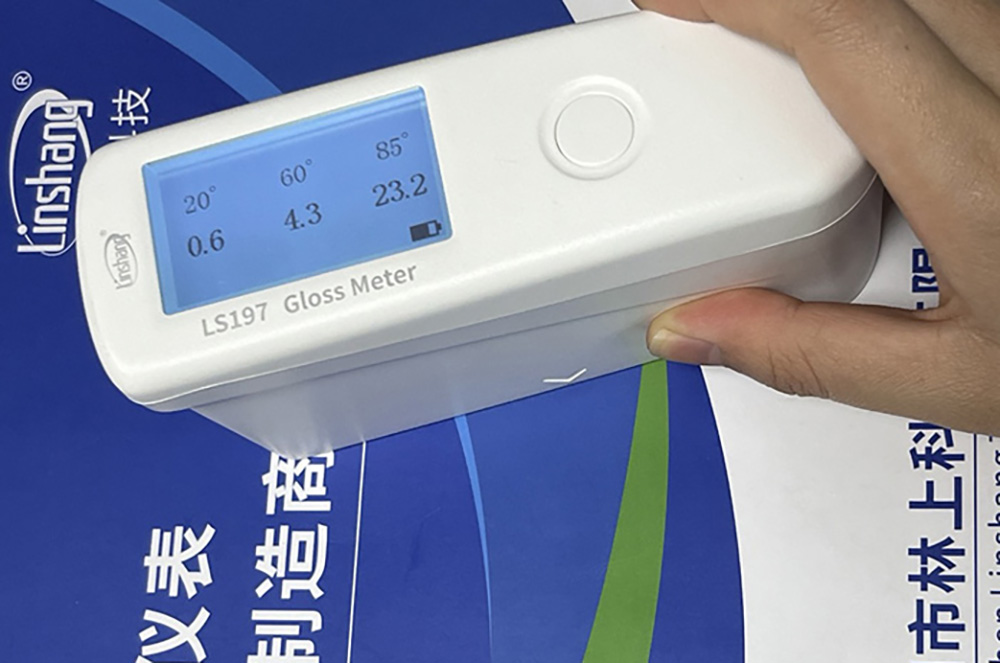

Many of the print gloss meters on the market today are very intelligent. We recommend the LS197 three-angle gloss meter, which is very accurate in measuring both high-gloss and low-gloss prints:

The instrument can be optionally calibrated when it is turned on, and readings are taken by placing the instrument directly on the specimen. The average of 3 measurements is taken as the result. If the difference between the two figures is higher than 2 gloss units, the sample is taken again for testing.

LS197 print gloss meter can accurately measure the surface gloss of different printed materials, which is an indispensable helper in the control of print appearance gloss. If you are interested in learning more about the Lin Shang Technology series of print gloss meters, please contact customer service.