Glass Thickness Gauge | Glass Thickness Measurement

In addition to measuring the thickness of single-layer glass, modern glass thickness gauges are also suitable for measuring various multi-layer stacked glass, insulating glass, laminated glass, etc. The glass thickness gauge mainly uses the laser reflection principle. When measuring the glass thickness, it only needs to be close to the side of the glass to complete the measurement. How to measure the glass thickness with glass thickness gauge, this article will provide you with detailed answers.

I. Glass thickness gauge principle and application

The glass thickness gauge uses the laser reflection principle. The glass thickness measurement can be completed only by placing the instrument on one side of the glass. In addition to measuring common glass (clear glass), you can also measure the thickness of a variety of hollow glass, three glass two cavity, laminated glass and multiple glass.

II. Best glass thickness gauge

Air interlayer and glass thickness of insulating glass can be measured

Range: glass thickness 70mm, air interlayer 34mm

Simple operation, fast measurement, light and portable

Measure the glass and air layer thickness, such as double glazed units, triple glazed units, laminated glass, etc.

Large LCD display for easy and fast reading

Auto mode and manual mode, the test accuracy reaches ± 0.1mm

III. How to measure glass thickness with glass thickness gauge?

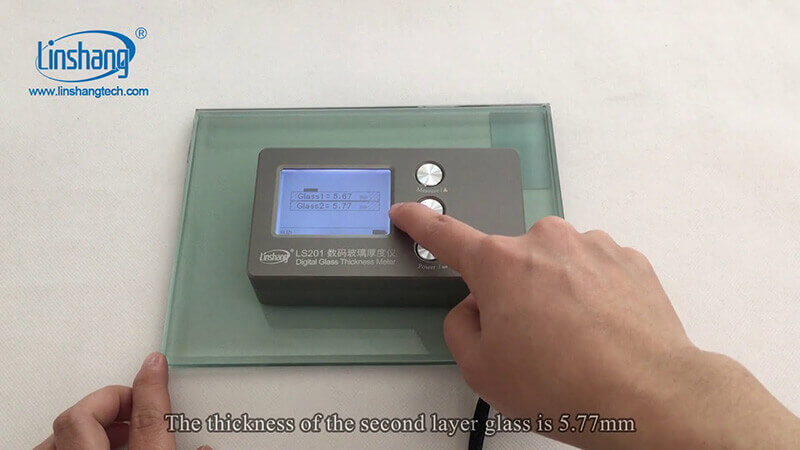

1. How to measure the triple glazed units with LS201?

Short press the power button to boot.

Place the glass thickness gauge closely on the glass.

Short press the Measure button to start glass thickness measurement.

Please watch the video below to learn more about the difference between the automatic mode and manual mode of the LS201 glass thickness gauge.

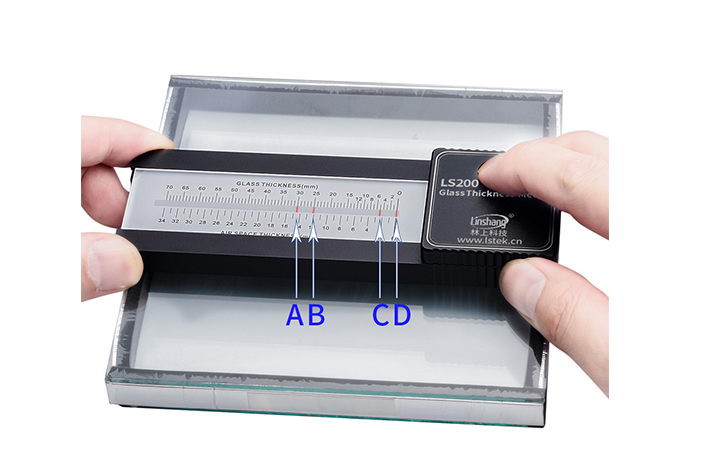

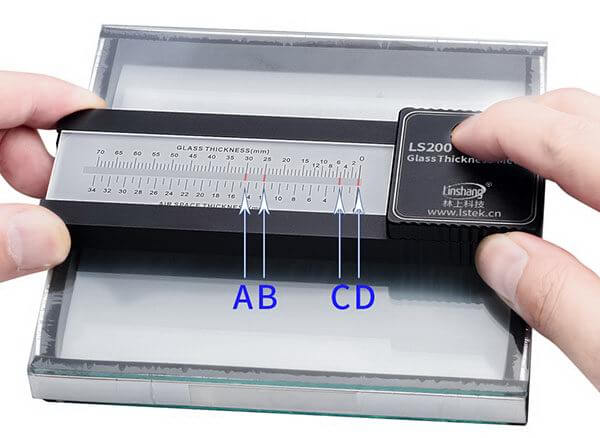

2. How to measure the insulating glass thickness with LS200?

Place the LS200 glass thickness gauge closely on the glass

-

Short press the red button on the right side of the LS200 glass thickness gauge

As shown in the figure above, when measuring insulating glass, four red light bars appear on the scale

C-D = the first layer glass thickness (ie 5-0 = 5mm)

A-B = the second layer glass thickness (ie 30-25 = 5mm)

B-C = air layer thickness (ie 12-2.5 = 9.5mm)

IV. Glass thickness specifications

3/32 inches thick (2 mm)-usually used for photo frames, etc.

1/8 inch thickness (3 mm)-used for windproof windows, photo frames, coffee tables, small cabinet door panels, thermal insulation devices and small desktops.

3 / 16-inch thickness (5 mm)-used for larger glass cabinet doors, single-pane glass windows, small mirrors, thermal insulation devices, etc.

1/4 inch (6 mm) thick (6.4 mm)-suitable for desktop (as a protective cover), heat insulation device, internal and external door glass, frame shower door, etc.

5/16 inches (8 mm)-used for desktop (as a protective cover), framed shower doors, etc.

3/8 inch thickness (10 mm)-used for shower room, desktop, glass wall and glass partition, etc.

1/2 inch thickness (12 mm)-larger shower door and enclosure, larger shelf, larger table top, work surface, glass wall and partition, manual railing.

5/8 inches (15 mm)-for shower doors, glass walls, glass partitions, handrails, etc.

3/4 inch thickness (19 mm)-for glass doors, table tops, glass floors, etc.

1 inch thick (25 mm)-for glass floors, stair treads, tables, glass furniture, etc. (less common).

In addition to measuring various types of glass, glass thickness gauges are more suitable for measuring various installed glasses, such as curtain wall glass of architectural buildings. As we all know, the glass thickness will affect the sound insulation and thermal insulation properties of the glass. But most window manufacturers tend to have lowest cost when complying with the minimum engineering requirements when producing and installing glass. In order to ensure that the glass performance meet the standard, the glass needs to be accepted after the glass installation is completed. Such test requirements are that many traditional thickness measurement tools cannot meet, but glass thickness gauges can.