Where are UV Energy Meters used?

Many things that we come into contact with in our daily lives need to go through the UV curing step, including the mobile phones we touch every day. Of course, from the development of the UV curing industry to the present era, it has tended to a relatively stable stage. After years of exploration and development by previous people, UV curing at this stage can be divided into two categories, namely the curing of high-pressure mercury lamp light source and the curing of UVLED light source.

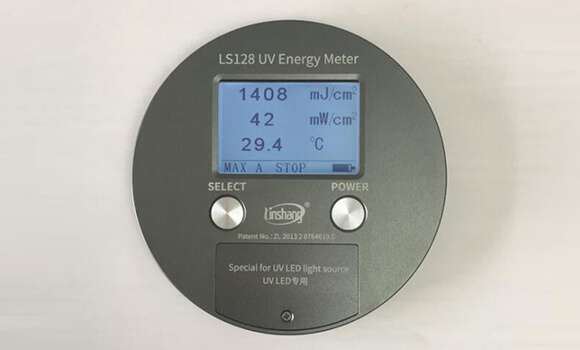

Due to the continuous improvement of technology, the technology of UVLED has been accepted by many manufacturers after the birth. However, there are still some manufacturers who have been using high-pressure mercury lamps for curing. In view of the above circumstances, Linshang Technology launched two types of UV energy meters to test different ultraviolet light sources. The LS120 UV energy meter is generally used to test high-pressure mercury lamps, while the LS128 UV energy meter is used to test UV LED lamps. The spectral range of LS120 is 315nm-400nm, because the spectrum of high-pressure mercury lamp is relatively wide. The spectrum of effective curing is only at 365nm, it is a very good choice to test high-pressure mercury lamp with LS120 UV energy meter. In addition to being able to test UV energy, this product can also test UV intensity and UV temperature. It is a multi-functional instrument.

The LS128 UV energy meter has a spectral range of 340nm-420nm. It has a wide variety of curing spectra for UVLEDs, including 365nm, 375nm, 385nm, 395nm or even 405nm and 415nm. However, the wavelength beyond 400nm has not played a very effective curing role, but the LS128 spectral range is basically a flat line between 340nm and 420nm, no matter which of the above curing spectra. And the LS128 UV energy meter has obtained a patent for invention. In addition to its powerful function, it can also withstand high temperatures. This UV energy meter can truly measure the actual temperature in the curing machine dynamically.

1. Application of UV energy meter in UV curing industry

(1) UV curing of electronic parts

Whether it is an office computer or a mobile phone that we cannot live without, the electronic components such as circuit boards are bonded by a special resin. This resin will automatically condense and solidify after being irradiated with the corresponding UV rays.

(2) UV curing of newspapers, books and periodicals

Popularized in the newspapers we read every day, or the books used by students, all kinds of inks can quickly dry out under the UV rays of the corresponding spectrum, so as to improve the printing efficiency.

(3) UV curing of outer coating

UV curing technology are used in automobile shells; toy exteriors; food packaging and furniture surfaces to fix the outer coating, which can be beautiful and safe (fire protection coating for the outer layer of some supplies).