UV Measurement Device for Cold Light Source UV Oven

1. What is cold light source?

Cold light sources are luminous light sources that contain almost no infrared spectrum. For example, the popular LED light source is a typical cold light source. The traditional incandescent and halogen light sources are typical heat sources. This light source is an excellent light source with flashing characteristics.When an object emits light, its temperature is not higher than the ambient temperature. We call this light source a cold light source.

2. What is UV oven?

UV ovens, also known as UV curing ovens, simply add ingredients that react chemically with ultraviolet light to materials such as paints, paints, adhesives, glues, etc. Then apply these materials to the cured material surface. The inside of the spread is converted into a polymer by ultraviolet irradiation in the curing oven to achieve the purpose of curing. The characteristics of this curing are: short drying time, low operating cost, high curing quality, less storage space and high cleaning efficiency. LED light sources are usually selected as the light source of the UV oven due to its advantages we mentioned above.

3. What is the relationship between the UV measurement device for cold light source UV oven?

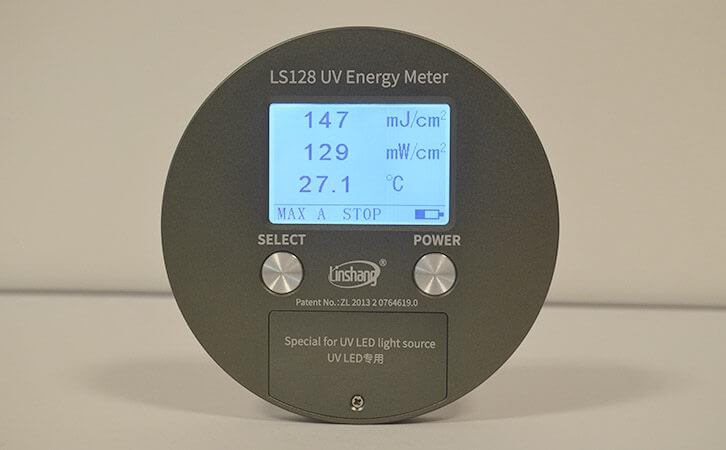

We take Linshang LS128 UV measurement device as an example:

Measurement of light intensity, energy and temperature of UV LED source

Spectral range: 340nm --- 420nm, instrument, calibrated at 395nm source

Power measurement range: 0 --- 40000 mW/cm2

Energy measurement accuracy: ±10%, ±5% typical

Sampling speed: 2048 times / s

The above parameters are the main parameters of the UV measurement device. "The light intensity of the UV LED source in the applicable function" indicates that this instrument is suitable for cold light sources because LED light sources are cold light sources. The key factor in determining the measurement accuracy in the above parameters is the "sampling speed". We know that cold light sources are characterized by flashing, so the energy value of light changes over time. The faster the sampling speed, the smaller the change in energy value. When the sampling speed is fast enough, we can say that the energy value is eternal. Therefore, the sampling speed directly determines the measurement accuracy of the UV measurement device. When the sampling speed of a UV measurement device is very slow, his measurement accuracy is definitely not good. Therefore, measurement accuracy and sampling speed are related.

Energy = power * time. Therefore, in the parameter table of the UV measurement device, the energy parameter is closely related to the power parameter. When the sampling speed is fast, the power value is more accurate. The more accurate the energy value measured with time is quantified.

Therefore, the UV measurement device for cold light source UV oven generally has the following characteristics:

With timing function, the UV measurement device can accurately calculate the curing time. Avoid too long curing time or too short curing time, resulting in defective products.

With intelligent statistics, you can view the temperature and intensity graphs. Making the uv energy value more intuitive.

The sampling speed is fast and the measurement accuracy is high. Really measure the actual temperature in the curing machine.

With high temperature resistance, the instrument can run at high temperatures of 100 degrees Celsius for a long time.

Built-in capacity, the instrument can store more than 60,000 data.

The above information is for the UV measurement device for cold light source UV ovens. We hope these sharing experiences can help you choose the UV measurement device for cold light source UV ovens. If you also want to know the UV measurement device used to test the high pressure mercury lamp, you can read "How to Choose Right UV Radiometer" for more information about Linshang UV energy meter.