Ultrasonic thickness gauges

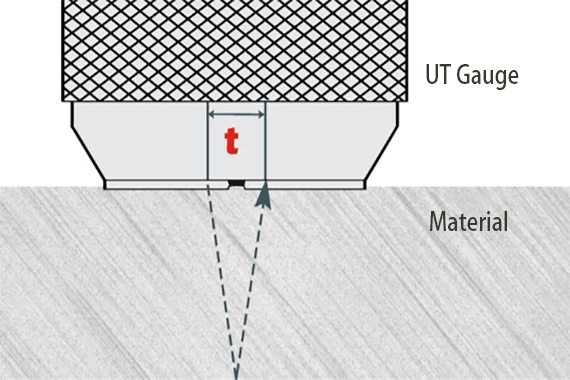

Ultrasonic thickness gauges (ultrasonic thickness testers, ultrasonic wall thickness gauges, ultrasonic thickness meters, etc.) measure the wall thickness of materials such as steel, plastic, and more using ultrasonic technology which is ideal for measuring the effects of corrosion on metal, pipes or any structure where access is limited to one side.

LS211 Ultrasonic Thickness Gauge

Non-destructive testing of material thickness, fast and safe

Large measuring range:0.8mm-600mm

High resolution:0.001mm

5 MHz dual-element-transducer probe

LS212 Ultrasonic Thickness Gauge

Non-destructive testing of material thickness, fast and safe

Measuring range:0.8mm-350mm

High resolution:0.001mm

Automatic Gain Function

LS213 Ultrasonic Thickness Gauge

Non-destructive testing of material thickness, fast and safe

Measuring range:0.8mm-350mm

Resolution:0.01mm

Select from wide range of sound velocity of various materials