LS211 Ultrasonic Thickness Gauge

Non-destructive for metal, glass, ceramics and plastics

With four kinds of probes, measuring a wide range of materials

Two measurement modes: QC Mode/Statistics Mode

Large measuring range: 0.8mm-600mm and high-sensitive dual-crystal probe

Automatic Gain switchable

Characteristics and Operation of LS211 Ultrasonic Thickness Gauge

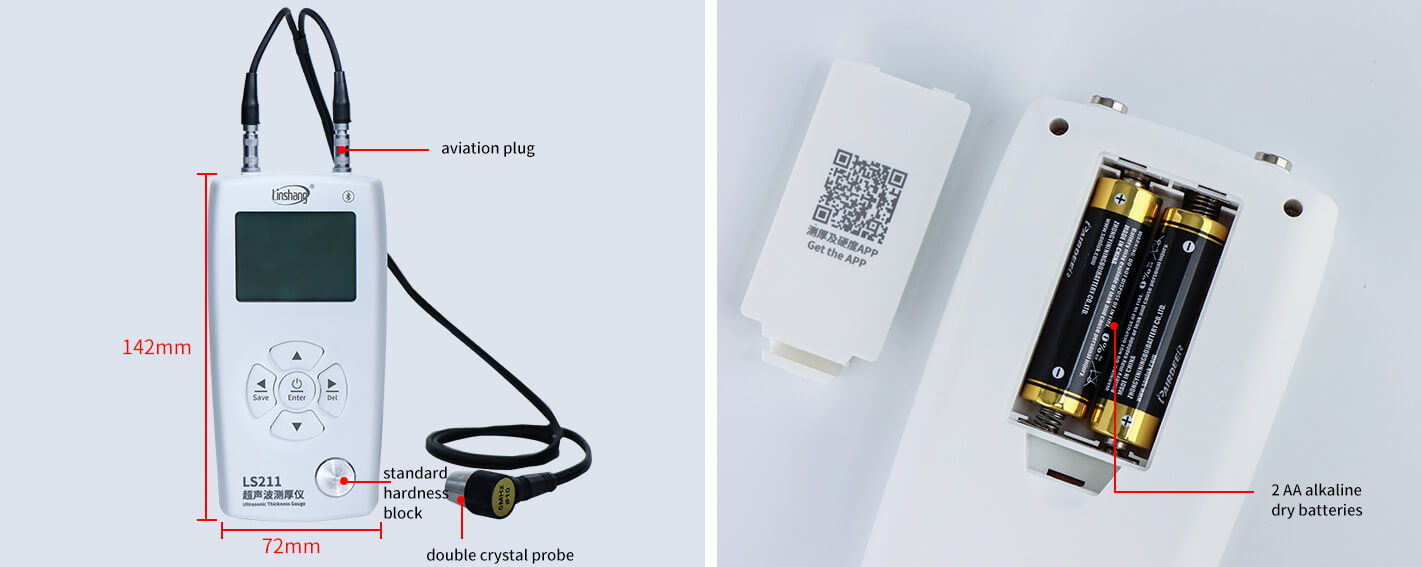

LS211 ultrasonic thickness gauge uses the ultrasonic pulse reflection principle for thickness measurement. The instrument can be equipped with four types of probes: standard probe, micro-diameter probe, coarse crystal probe and high temperature probe, and is professionally used for thickness measurement of metals (such as steel, aluminum, copper, etc.), plastics, ceramics, glass and other materials that can transmit ultrasonic waves. The instrument adopts professional timing chip design, the resolution is up to 0.001mm.

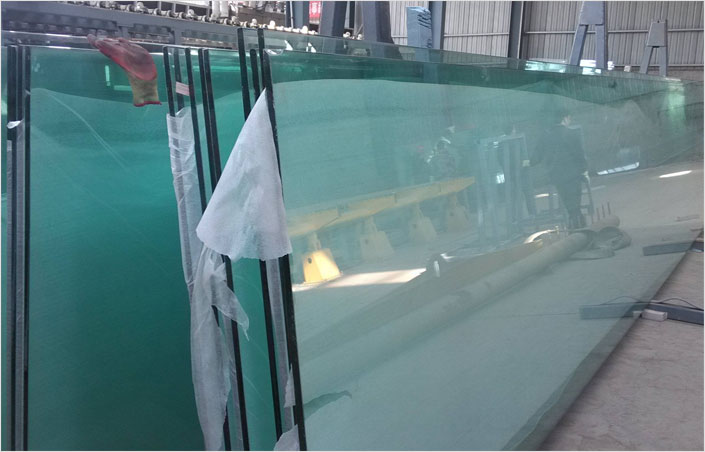

Application

In many industries, It is essential to mesure the wall thickness to confirm the condition of the material for the normal running of the items or structure safety. LS211 ultrasonic thickness meter can be widely used in testing the thickness of various accessories or metallic structure to check them whether to be repaired or changed such as ships, tanks, pipes or steel structure. The gauge is applicable for petroleum, chemical, metallurgical, shipbuilding, aviation and aerospace various fields.

Parameters

1. Probe specifications and parameters

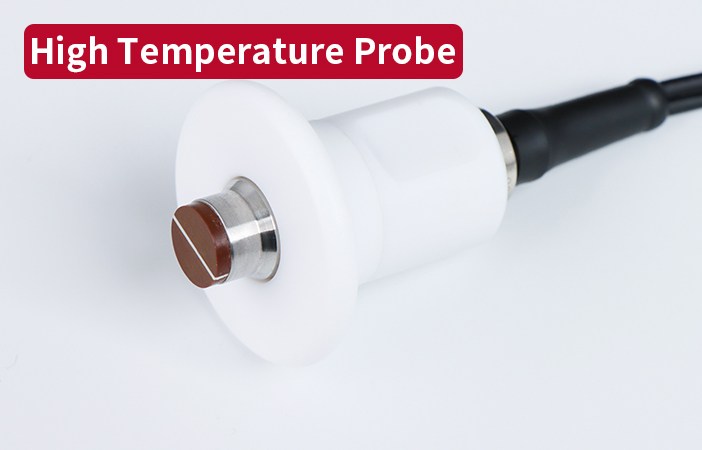

| Probe | Standard Probe | Micro-diameter Probe | Coarse Crystal Probe | High Temperature Probe |

|---|---|---|---|---|

| Probe Model | 5MHZφ10 | 7MHZ PT-06 | 2MHZ ZT-12 | 5MHZ GT-12 |

| Minimum measuring area | φ10mm | φ6mm | φ12mm | φ12mm |

| Probe size | φ18*26mm | φ15*25mm | φ18*28mm | φ43*48mm |

| Measuring Range (45#steel) |

0.8-600mm | 0.75-80mm | 3-200mm | 3-200mm |

| Accuracy (H is the standard value) |

H<10mm:±0.05mm H≥10mm:±0.5%H |

H<10mm:±0.05mm H≥10mm:±0.5%H |

H<10mm:±0.1mm H≥10mm:±0.5%H |

H<10mm:±0.05mm H≥10mm:±0.5%H |

| Pipe measurement lower limit (45# steel) |

φ20*3mm | φ20*2mm | φ30*4mm | φ30*4mm |

| Exposure temperature | -10~60℃ | -10~60℃ | -10~60℃ | -10~500℃ |

| Application | Measure conventional workpieces | Measure surfaces and small workpieces | Cast iron and some materials with large crystal particles | Measure high temperature workpieces |

2. Host parameters

| Parameter | Value |

|---|---|

| Resolution | 0.8-10mm:0.001mm 10-100mm:0.01mm 100-600mm:0.1mm |

| Sound Velocity Range | 1000~9999m/s |

| Display | 240 * 160 dot matrix LCD |

| Unit | mm/inch |

| Power Supply | 2pcs of 1.5V AA alkaline battery |

| Host Size | 142 * 72 * 28 mm |

| Weight | About 230g |

| Operation Temperature Range | -10~50℃,0~85%RH(No condensation) |

| Storage Temperature Range | -10~60℃,0~85%RH(No condensation) |

Features

Excellent Timer chips provide fast, accurate readings

LS211 ultrasonic thickness gauge calculates the material thickness by sound velocity and the time taken between the emitted pulse and the detected echo, a precision timing chip can bring the user the accurate time to get the accurate data

Ultrasonic double crystal probe

The gauge probe employs a double crystal transducer consisted of two independent crystals separated by an acoustic barrier. One crystal sends ultrasonic pulses, and another is responsible for receiving them. The probe is highly sensitive and can effectively reduce clutter, and the probe housing is made of stainless steel, which is hard and durable

Match four kinds of probes, intelligent identification of probe

The instrument can be matched with four types of probes: standard probe, micro-diameter probe, coarse crystal probe and high-temperature probe, with intelligent identification of the probe model, and the instrument adapts to the display interface according to the probe type.

Automatic Gain switchable

Some materials are good conductors of sound and some are not. For the latter, the meter can switch the Gain freely which is to amplify the ultrasonic signal so that the emitted pulse is accurately captured by the transducer as it propagates, and obtains accurate data

High precision ensures LS211 can pass Chinese authoritative metrology institute

The accuracy of LS211 ultrasonic precision thickness tester can reach ± 0.05mm when testing materials 0.8-10mm thick, and the accuracy is ± 0.5% reading during 10-600mm thickness range. The gauge can pass the inspection of Chinese national authoritative metrology institute

With E-E measurement mode

When there is a coating or paint layer on the surface of the workpiece, it will make the measurement results inaccurate. The standard probe with penetration coating measurement mode can accurately measure the actual thickness of the substrate under the workpiece coating without removing the coating from the workpiece surface.

Bluetooth APP function

The instrument has built-in Bluetooth communication module, which can be connected to cell phone APP to achieve multiple data storage and measurement data sharing.

Extra large storage, 999 data saved

A total of 999 data can be stored in the instrument, which can be viewed at any time, preventing data loss.

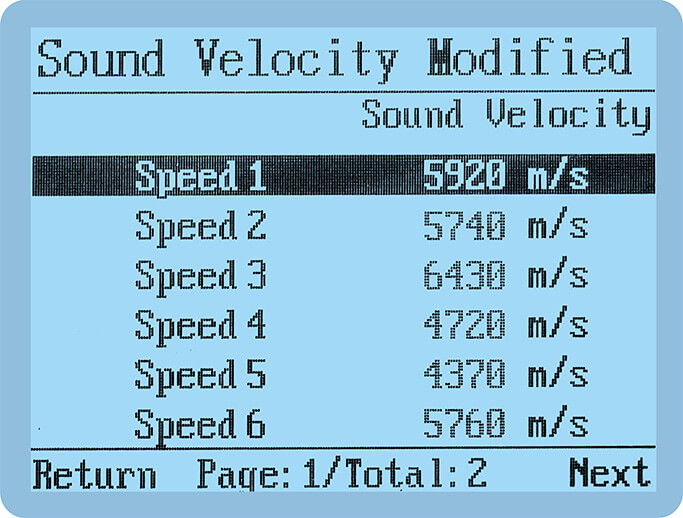

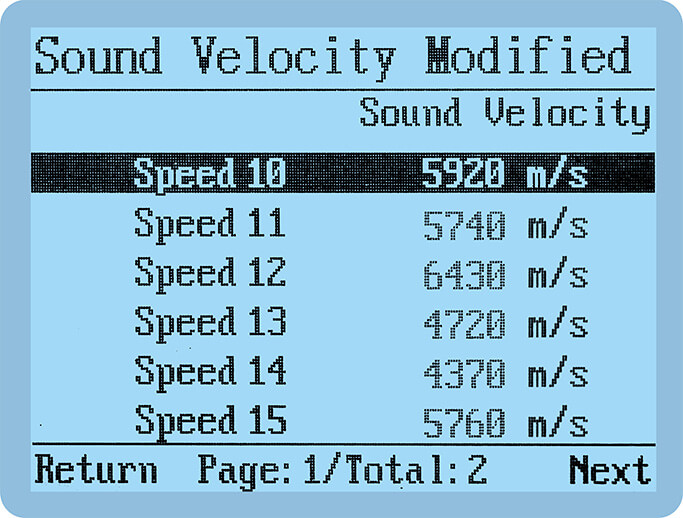

Customised storage of 18 material sound velocity

When there is no corresponding material in the instrument, the user can customise the storage of material sound velocity value. In the "Set by thickness" and "Manual input" interface each has 9 sound velocity data, which can be modified and saved at any time to meet the needs of various material thicknesses testing.

Set by thickness interface

Manual input interface

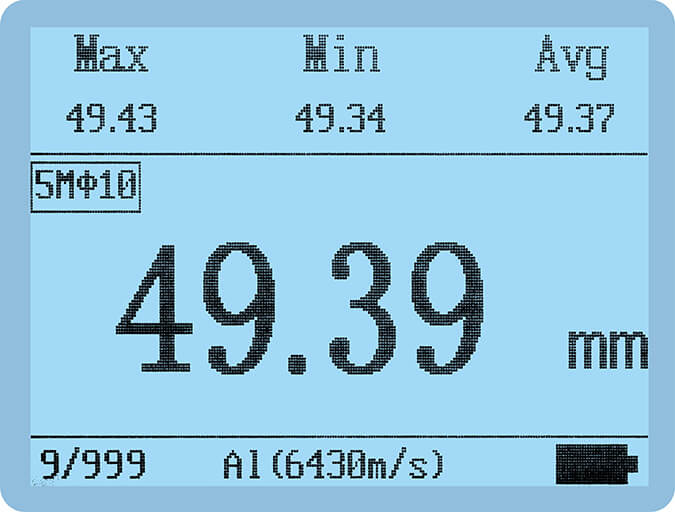

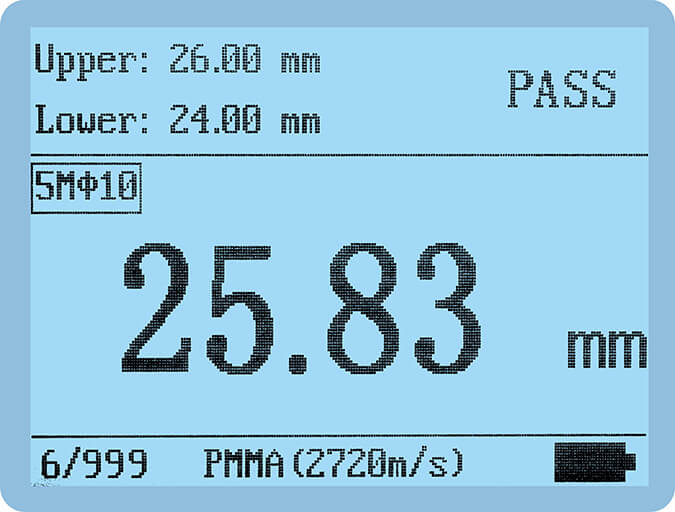

Two measurement modes: QC Mode/Statistics Mode

LS211 ultrasonic thickness tester features two measurement mode: QC mode and statistics mode

Allowing to set upper and lower limits to check the problem areas by prompting NG under the QC mode. It will count maximum, minimum and average values of data in Statistics mode

Statistics mode

QC mode

Built-in sound velocity of multiple materials

LS211 already contains the velocities of several common metallic (such as iron, copper, aluminum) and non-metallic materials (plastics, ceramics, plexiglass) as well as other objects and the user are not required to find them separately

Large measuring range of thickness

The instrument with standard probe can measure 0.8mm-600mm thickness of the material, to meet the measurement needs of most users.

Various materials can be measured accurately

As a non-destructive testing tool, LS211 ultrasonic thickness gauge uses dual-crystal transducer and a little amount of ultrasonic couplant to assist in detecting the thickness of substrates, able to measure the thickness of most materials, such as steel, plastics, glass, ceramics and so on.For surface measurement, the split surface of the probe should be measured perpendicular to the axis of the surface.

Comfortable grip with non-slip silicone keys

LS211 ultrasonic thickness gauge housed in ABS plastic shell with non-slip silicone keys, has a comfortable grip and easy to operate

LCD Screen offers users relaxing reading experience even in the backlit environmet

Evident keypad, Simple using methods for quick menu navigation

Inch/mm switchable

Selectable display languages

Qualifications and Standards

LS211 conforms to the following standards:

JJF 1126-2044 Calibration Specification for Ultrasonic Thickness Instruments

Software Download

The LS211 Ultrasonic Thickness Gauge is equipped with an APP that supports Android OS version 7.0 and higher. It can be installed through the following ways:

1) Scan the QR code on the instrument with your mobile browser, follow the instructions to download and install.

2) Click the link https://www.linshangtech.cn/a/253/ to install the APP.

3) Search for "UT and HL" (not case sensitive) in the APP Store/Google Play to install the application.

Videos

Operation video

App operation video

Ultrasonic thickness gauge measures glass bottle bottom thickness

Ultrasonic thickness gauge for measuring large thickness materials

LS211 ultrasonic thickness gauge measures mold steel thickness

Ultrasonic thickness gauge measured the thickness of this stainless steel pipe

Comparison of three sound speed settings of ultrasonic thickness gauge

Your product information request

Please let us know your requirements and we will be in contact with you shortly!