What is a Webster hardness tester?

The Webster hardness tester is an important tool for measuring the hardness of metals. It is widely used in hardness testing in industrial production and metal processing due to its accurate measurement method and convenient operation. Hardness measurement is a key link in quality control, because the hardness of metal materials not only reflects their strength and wear resistance, but also directly affects processing performance and service life.

How does a Webster hardness tester work?

The work principle of the Webster hardness tester is to press a steel indenter of a specified shape into the surface of the sample under a certain test force, and use the depth of the indenter to indicate the hardness of the material. The indentation depth of 0.0125mm (generally directly approximated to 0.01mm in actual use) is defined as a Webster hardness unit, represented by HW. The hardness of the material is inversely proportional to the indentation depth. The shallower the indentation, the higher the hardness, and vice versa.

Calculation formula: HW=20-L/0.0125

In the formula, "HW" represents the Webster hardness symbol, "L" represents the depth of the indenter into the sample, in millimeters (mm), and "0.0125" is the specified value.

Based on the Webster hardness measurement principle detection, the Linshang digital Webster hardness tester adopts the eddy current induction principle measurement technology to measure the distance between the indenter and the coil, thereby inversely calculating the depth of the indenter into the material being tested. Eddy current technology can sensitively capture tiny physical changes through electromagnetic induction, and has higher repeatability and test accuracy.

How to measure the Webster hardness?

The Webster hardness tester is a portable metal hardness testing instrument that can be operated with one hand. It can test the hardness of materials quickly, conveniently and non-destructively. No sampling is required during the test, and the operating skills are not high. It is very suitable for rapid hardness testing of materials at the production site.

The operation method of the Webster hardness tester is very simple. Just place the test workpiece between the anvil and the indenter, and then apply pressure to the handle until the indenter is pressed to the bottom and remains motionless. At this time, read the hardness value.

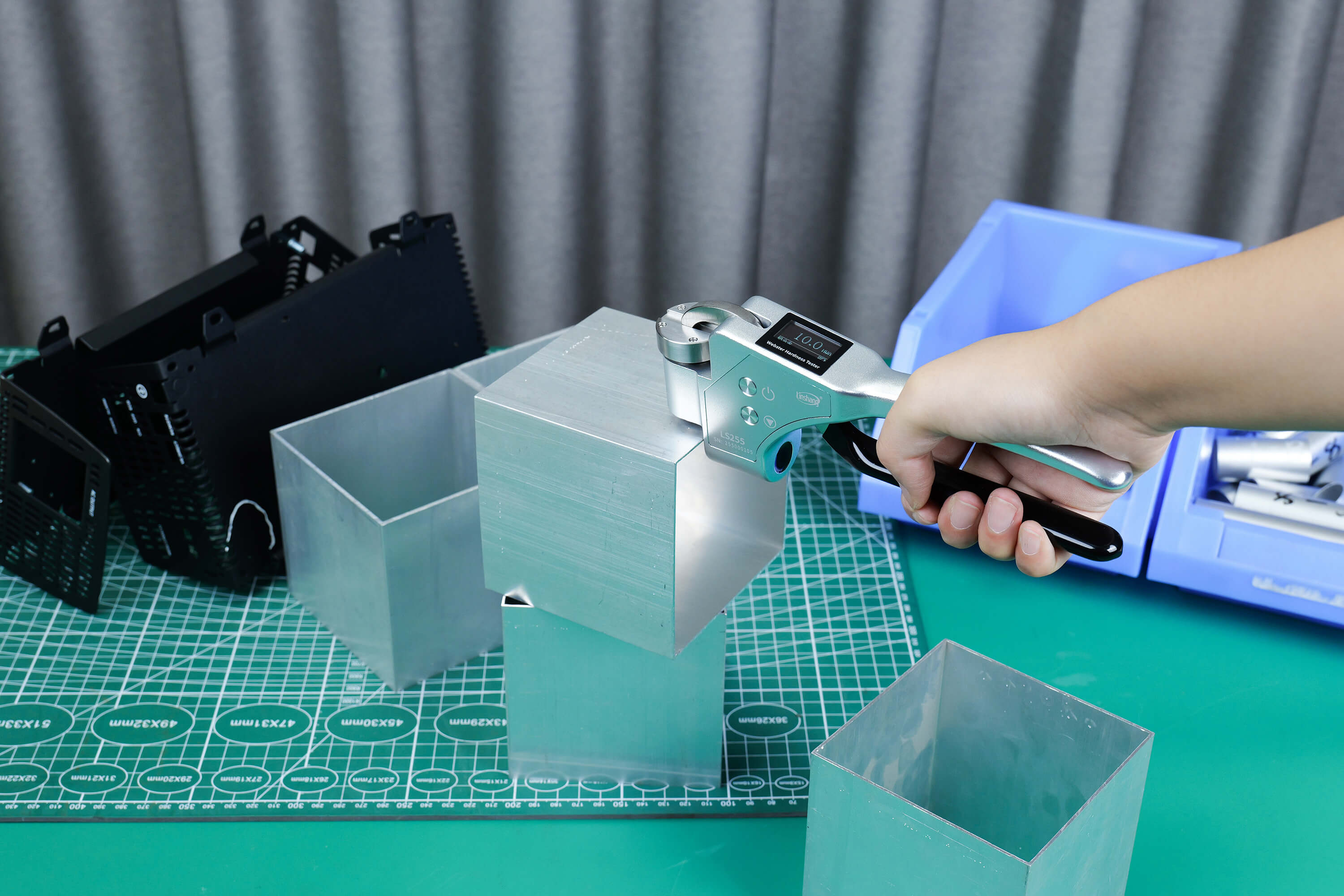

Example: LS255 Webster hardness tester measures aluminum workpiece

First, place the test object between the anvil and the indenter.

The surface of the test piece should be perpendicular to the indenter, and the bottom of the test piece should touch the anvil.

Then, press the handle down firmly until the indenter reaches the bottom and stays in place.

After hearing the buzzer, the value displayed by the screen is the measured hardness value.

Clamping the workpiece

The hardness value is displayed directly on the screen

Different types of Webster hardness testers

Generally speaking, Webster hardness testers are mainly divided into two categories: dial type and digital display type.

Currently, most of the Webster hardness testers on the market are dial type, which display the hardness value through a mechanical pointer and a dial. When using it, the operator needs to manually read the scale on the dial, and it is further divided into type A and type B, which are used to test different metal materials.

The digital Webster hardness tester is equipped with a digital display screen, which are obtained through eddy current sensing technology that measures changes in eddy currents.

The digital Webster hardness tester is equipped with a digital display and uses eddy current sensing technology to measure changes in eddy currents. The instrument's internal microprocessor converts these changes into specific hardness values, which are directly displayed on the screen, enabling effective measurement of the hardness of various types of metals.

Dial-type Webster hardness tester

The difference between the dial Webster hardness tester and the digital Webster hardness tester

In metal hardness testing, the dia Webster hardness tester is a traditional tool widely used in the aluminum processing industry. It displays the hardness value through a mechanical pointer and a dial, which is easy to operate, but requires manual reading and calculation. In contrast, the LS255 digital Webster hardness tester newly launched by Linshang represents a technological innovation. It uses digital screen and eddy current sensing technology, which not only improves the measurement accuracy, but also simplifies the operation process.

Next, we will discuss in detail the differences between the two Webster hardness testers in terms of instrument use, test accuracy, calibration methods, etc.

1. Instrument Operation:

The operation process of the dial Webster hardness tester is relatively manual and relies on manual judgment. First, the operator needs to place the indenter of the hardness tester vertically on the metal surface to be tested. Then, apply pressure to the handle until the "bottom" is felt. The operator must manually estimate the reading on the dial. It is important to apply a steady, uniform force to the handle during the reading process. Otherwise, the pointer will shake, and the reading will be unclear. The LS255 digital Webster hardness tester only needs to apply enough force to press once. After hearing the beep, the hardness value is directly displayed on the screen, eliminating the process of manual calculation and reading. Even if the material being tested is removed, the reading can still be easily seen, preventing the display from being obstructed and ensuring the value is clearly readable.

2. Measurement Accuracy:

Since the dial hardness tester relies on mechanical structure and manual reading, the measurement accuracy is often affected by human factors. For example, the error when the operator reads the dial pointer, or the uneven force when pressing, will cause the error of the hardness value. In addition, the accuracy of the dial hardness tester is greatly affected by external factors such as temperature changes and friction. The digital Webster hardness tester uses digital sensors and sophisticated electronic systems to provide higher measurement accuracy( up to 0.1 HWA). Its digital screen can directly display the hardness value, avoiding the error of manual reading. In addition, the sensor of the digital hardness tester can accurately measure the indentation depth and automatically calculate the hardness value to ensure the consistency and reliability of the measurement results. Therefore, the digital hardness tester has obvious advantages in applications with high precision requirements.

3. Calibration Method:

The dial Webster hardness tester needs to be disassembled during calibration, and the dial needs to be adjusted with a screwdriver to complete the benchmark adjustment, which is complicated and cumbersome. The LS255 digital Webster hardness tester has a non-disassembly benchmark adjustment function, which can be adjusted by simply pressing the handle. Users can also eliminate test errors by calibrating the standard block, which is simpler and faster than the dial Webster hardness tester.

4. Data Storage:

Since the dial Webster hardness tester is a traditional mechanical instrument, it usually does not have a data storage function. In addition to the built-in storage function, the LS255 digital Webster hardness tester is also equipped with a Bluetooth function, which can be connected to a mobile phone APP for use, and can store massive data in groups for subsequent viewing and analysis.

5. Hardness Scale Switching:

The range of the Webster hardness tester is generally 0-20HW, equivalent to 25-110HRE. If you want to switch to other hardness scale for the dia Webster hardness tester, you need to find a conversion table for calculation. The LS255 digital Webster hardness tester has six built-in hardness scales: HWA, HRE, HRF, HRB, HV, and HB, which can be switched directly in the instrument.

6. Maintenance and durability:

Due to the use of mechanical structure, the durability of the dial Webster hardness tester may be worn out in long-term use, especially the dial and pointer parts. Regular maintenance and cleaning are necessary, otherwise it is easy to affect the accuracy of the measurement. Wear of the mechanical part may also lead to unstable test results, requiring more frequent inspection and maintenance. The electronic structure of the LS255 digital Webster hardness tester is relatively modern. Although the electronic components may be affected by battery life or external impact, they are more durable and relatively simple to maintain. Due to the technological advances in digital screen and sensor, the service life of digital hardness testers is generally longer, and the frequency and difficulty of maintenance are lower.

There are some obvious differences between the dial Webster hardness tester and the digital Webster hardness tester. The dial Webster hardness tester relies on mechanical structure and manual reading, which is easily affected by subjective and objective factors and is suitable for applications with simple or low precision requirements. The digital Webster hardness tester provides higher measurement accuracy and ease of use through eddy current sensing technology and digital display. It is particularly suitable for industrial production applications with high precision requirements and frequent use.

Features of LS255 digital Webster hardness tester

As the latest high-precision hardness tester, Linshang LS255 Webster hardness tester represents technological innovation and breakthrough in the field of Webster hardness measurement. Compared with the traditional dial hardness tester, LS255 not only achieves significant improvement in measurement accuracy and ease of operation, but also integrates a number of advanced functions to meet the high requirements of modern industrial production for hardness testing. The following will introduce the core features of LS255 in detail to help you have a more comprehensive understanding of how this hardness tester can bring higher efficiency and reliability to your production and quality control.

● Digital display design

The top of the instrument is equipped with an OLED digital screen, which is simple and convenient to read. Avoid errors caused by observing the dial with the naked eye.

● Automatic data locking

The instrument has an automatic data locking function, and you can easily read the value without pressing the handle all the time, avoiding the inability to read the value due to the display device being blocked.

● Free switching of multiple hardness scales

The tester has six built-in hardness scales, which can be freely switched between HWA, HRE, HRF, HRB, HV and HB, no more tedious manual check table.

● Non-disassembly reference adjustment and hardness calibration technology

LS255 Webster hardness tester has a non-disassembly reference adjustment function, and the adjustment can be completed by directly pressing the handle; users can also eliminate test errors by calibrating the standard block, which is simpler and faster than the traditional Webster hardness tester calibration.

● High accuracy and good repeatability

The instrument's measurement accuracy is ±0.5HWA, and the repeatability can reach 0.5HWA, ensuring that it passes the inspection of the National Authoritative Metrology Institute.

● Can store 9 sets of data

The tester has a built-in storage chip , can store 9 results, meeting the user's needs for multiple measurements of the object being measured.

● 0.1HWA high resolution

LS255 adopts eddy current induction principle measurement technology, with a resolution of up to 0.1HWA, and more accuracy.

● Equipped with mobile APP to realize data export and sharing

The instrument is equipped with a mobile phone APP, which can be tested online, supports massive storage, and exports and shares test results.

● Free standard Webster hardness block

Provide free standard Webster hardness block, which is strictly measured in accordance with the metrological verification procedures, and the surface roughness and flatness meet the requirements of the regulations.

● High hardness imported indenter

High hardness, good toughness, longer service life and more durable.

● Small size, easy to carry

It is a portable teser with small size, light weight, and can be operated with one hand. It is particularly suitable for rapid and non-destructive qualified inspection of product hardness at production sites, sales sites or construction sites.

● Comfortable grip

The body is made of forged aluminum alloy and anodized, which is comfortable to hold, wear-resistant and pollution-resistant.

LS255 Webster hardness tester features video

Application

The Webster hardness tester is widely used in many industries, especially in metal processing, materials science research and quality control. In the metal processing industry, the Webster hardness tester is often used to measure the hardness of materials such as aluminum alloys, mild steel, and brass, helping manufacturers to ensure that the raw materials meet the strength and wear resistance requirements to ensure the quality and performance of the final product. Especially in the fields of automobiles, aerospace, etc., which have extremely high requirements for material strength, the Webster hardness tester is an important tool for quality control. In addition, the application of the Webster hardness tester in scientific research, heat treatment, wear-resistant material testing and other fields further demonstrates its wide applicability in material performance evaluation. Whether in traditional manufacturing or in emerging industries, the Webster hardness tester provides companies with accurate hardness measurement solutions to ensure that every product meets the required performance standards.

It can distinguish between materials before and after heat treatment, which is convenient for checking the most suitable heat treatment conditions.

It can determine whether the material is made of inappropriate alloy processing and whether the alloy composition of the material is qualified.

Determine whether the aluminum product is aged, or whether the hardness is within the specification range, and can distinguish different types of aluminum materials and different aging states.

Measure long, heavy workpieces or assemblies that are inconvenient to send to the laboratory.

Used for aluminum profile production inspection, acceptance inspection and quality supervision inspection.

Can measure a variety of aluminum profile shapes.

Can be used in conjunction with fixed laboratory hardness testing equipment.

2. Automatic data locking, easy to read

3. Providing a variety of hardness scales

4. No-disassembly reference adjustment and hardness calibration technology

5. High precision, pass authoritative metrology inspection

FAQs

-

1.What are the precautions for using a Webster hardness tester?

a. Try to use as little air pressure as possible on the instrument to avoid damaging the indenter too quickly, which will affect the stability of the instrument and the accuracy of the data.

b. The surface of the sample should be clean. Surface dirt or coating will affect the measurement accuracy.

c. When measuring, the distance between any two indentations should not be less than 6mm, and the distance between the center of the indentation and the edge of the object being measured should not be less than 5mm.

d. When measuring, you need to press it hard to the bottom at one time. Do not press it slowly.

e. The measurement accuracy will be reduced for hardness below 4HWA or above 17HWA.

-

2.How to perform reference adjustment on the LS255 Webster hardness tester?

When different users use the instrument for the first time or when the instrument is pressed without a material but it does not display 20 HWA, please follow the steps below to carry out the reference calibration:

The test slot is empty, press the handle directly to the bottom, and the instrument will display a measurement value. Press the handle tightly, short press the power button, and after hearing the buzzer prompt, the instrument will prompt "Reference Cal Relax The Handle." After releasing the handle, the instrument displays "20.0HWA" to indicate that the adjustment is successful.

-

3.How to calibrate the LS255 Webster hardness tester?

Short press the power button to enter the main menu, select the "CAL", and the screen prompts "Test Standard" and flashes. At this time, the standard hardness block can be measured (single or multiple times). If the measured value is not within the range of 0-20HWA, the instrument prompts "Exceed the limit". If the measured value is within the range, the cursor moves to the actual value area. At this time, short press power button and down button can adjust the actual value to the standard value of the hardness block. Long press the power key to save the calibration value. After prompting "Calibration successful!", it automatically returns to the main menu interface.

-

4.How to switch the hardness scales of the LS255 Webster hardness tester?

The LS255 Webster hardness tester has multiple built-in hardness scales that can be switched freely:

Short press the power button on the measurement interface to enter the main menu, select the required hardness scale, and then test the material. If the measured hardness value is not the Webster, you need to select the corresponding material first to measure accurately.

-

5.Why should the Webster hardness tester be calibrated?

Over time, the mechanical parts of the hardness tester (such as the indenter) may show slight wear or deviation due to use, which may affect the measurement accuracy. At the same time, environmental factors such as temperature, humidity and air pressure may affect the operation of the hardness tester, especially when used in different environments, which may cause deviations in the measurement results. In addition, even if the hardness tester has undergone rigorous inspections before leaving the factory, system errors may gradually occur due to slight collisions, vibrations or aging of internal electronic components that may occur during use. Regular calibration can effectively detect and eliminate these potential errors and avoid unnecessary deviations affecting the measurement results.

The above is the full content of this article. Welcome to consult our customer service for more information about LS255 digital display Webster hardness tester.