Non-contact vacuum coating thickness measuring system

On April 1, 20, Linshang Technology shipped another vacuum coating thickness measuring system. This is a three-point online tester.

Linshang LS152 vacuum coating thickness measuring system is a product completely tailored to customer needs. Compared with other portable testing equipment, the price is relatively high. And custom products are generally not returned, so why do so many customers choose to customize it?

1. LS152 Vacuum coating thickness measuring system has a good reputation, often introduced by old customers.

Linshang LS152 vacuum coating thickness measuring system has been widely used in roll vacuum coating industry, optical film industry, gold foil industry, glass production and other fields. The recognition of these users has brought very good marketing results to this product. No matter from the technology or the service, it has been well received by users. Kunshan Weilan Technology Co., Ltd., which ordered 3 points this time, was introduced to us by old customers. Here, we also thank customers who recommended this vacuum coating thickness measuring system.

2. LS152 Vacuum coating thickness measuring system is easy to install and simple to operate and users do not worry about after-sales and maintenance.

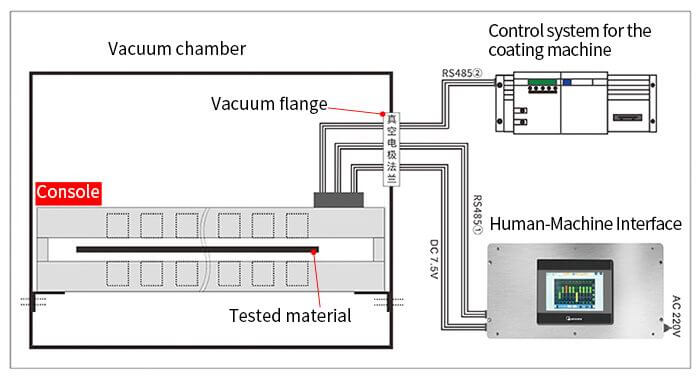

Linshang LS152 vacuum coating thickness measuring system has a very big advantage, no matter how many sets of test points are customized by the user, only two output lines are needed. One for power lines and one for RS485 communication lines. This is a feature not available in the same type of equipment abroad. After ordering this equipment, users only need to connect the power supply and RS485 communication line and then they can be put into production.

3. LS152 Vacuum coating thickness measuring system can effectively improve production efficiency and product quality

Linshang LS152 vacuum coating thickness measuring system can support dual RS485 outputs. For users who need to connect to PLC, the equipment can be connected to PLC through RS485 interface to achieve closed-loop control. In the production process, it can quickly and automatically adjust the control quality to avoid errors or unresponsiveness caused by human detection, which can improve production efficiency and quality and help reduce production costs.

Linshang LS152 vacuum coating thickness measuring system is based on the principle that the transmittance (optical density) of the material is proportional to the coating thickness. As long as the material is transparent to light, the quality of the product can be monitored by monitoring the transmittance (optical density). If you are also interested in this product, please check the following parameters:

| Parameters | LS152 |

| Test wavelength (optional) | Green light: 530nm |

| Infrared | 850nm |

| Measuring spot | 5mm |

| Transmittance measurement accuracy | Better than ±1% |

| Transmittance resolution | 0.005% |

| Optical density measurement range | 0.00 OD - 5.00 OD |

| Optical density resolution | 0.01 OD for 0.00-3.00 OD |

| Maximum measurement points | 45points |

| Distance between adjacent probe | Minimum distance of 35mm |

Distance between receiving probe |

20mm |

| Temperature range | -10°C - 60°C |

| Storage temperature | -20°C - 70°C |

| Relative humidity | less than 85%, no condensation |

| Data refresh cycle | Normal mode 300ms/ Fast mode 100ms |

| Communication interface | Dual RS485 |

| Communication protocol | MODBUS protocol |

| Dimension | 80mm(W)*180mm(H)*L(Customized) |

| Vacuum flange electrode cores | 6 ( RS485①+DC7.5V) |

| Power supply | 220V AC/50Hz |

For more customer applications of Linshang LS152 vacuum coating thickness measuring system, please click the text below for details:

- Linshang Insulated Glass Unit Measuring Tools

- Spectacle lens anti-blue light detection---blue-violet light transmittance meter

- Measurement of Optical Density

- Difference of LS116 Transmission & LS117 OD Meter

- Difference between LS116 and LS117 Light Transmittance Meter

- What’s the Difference Between Point Light and Parallel Light Transmittance Meter