Things You Should Know About Anticorrosive Coating

In order to ensure the quality of food in daily life, we will carry out anti-corrosion measures such as refrigeration, preservation, sealing and so on. In most cases in industrial production, the production environment is relatively harsh for the instrument. It is necessary to take coatings to improve the accuracy of various instruments or engineering equipment. Therefore, the application of anticorrosive coatings has been developed. With the use of anticorrosive coatings, professional paint thickness measuring instruments have also been produced to measure the thickness of anticorrosive coatings.

The industrial method of using anticorrosive coatings is mainly to add anticorrosive coatings to the instruments that need to be anticorrosive. Generally, the main coatings used in industry are galvanizing. Galvanized coating can achieve a stable effect and reduce the occurrence of chemical reactions, so it has a good performance in corrosion and rust prevention. There are also differences in the galvanized layer. The galvanized layer can be divided into a galvanized layer and a hot-plated layer. When the coating is intact, the hot-dip galvanized layer has better corrosion resistance than the electro-galvanized layer. Therefore, in industry, coatings for hot-dip galvanizing for anti-corrosion coatings are more widely used than galvanizing. Under the same conditions, the anticorrosive effect is better.

The composition of the anticorrosive coating is generally divided into three structures. The primer applied on the metal surface is used to add the first anticorrosive coating on the surface of the object. First, the adhesion between the metal and the main coating is enhanced, so that the coating can accept the corrosion of various objects and play a role on the object surface. The second layer of the anticorrosive coating is the main coating. This layer is also the most important part for the anticorrosive effect. The main coating of the second anticorrosive coating is coal tar enamel, polyethylene adhesive tape, petroleum asphalt, epoxy Resin and other materials. With these materials, it is possible to ensure that the anticorrosive coating has a better insulation effect against rust and mold. The third layer of the anticorrosive coating is a bandage. This layer is mainly for protection. It is used to maintain the mechanical strength of the anti-corrosion coating itself and to prevent the anti-corrosion coating from being damaged during transportation and construction after the coating is finished. After the construction of the anticorrosive coating is completed, it cannot be put into use immediately.

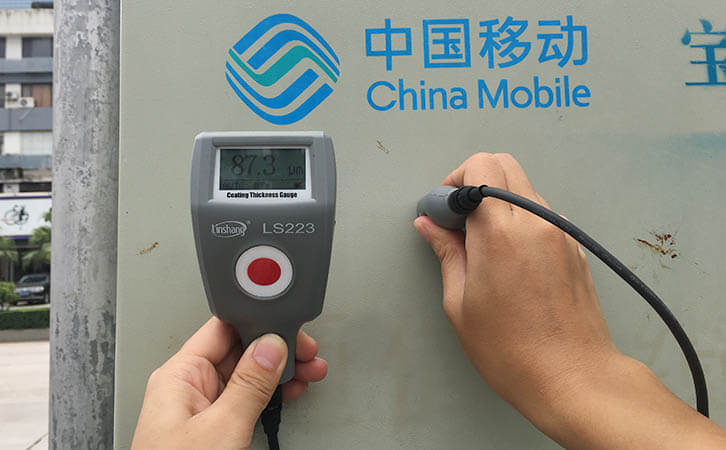

The market demand for anticorrosive coatings in China is very large. According to the new coating standard (PSPC), there are also stricter standards for the thickness of anticorrosive coatings. The thickness of the anticorrosive coating has a significant effect on the anticorrosive effect. Therefore, it is necessary to use an anticorrosive paint film thickness gauge. The anti-corrosion paint thickness measuring instrument can detect the thickness of anti-corrosion coating of different materials. Comparing the measurement results with the standard requirements will help us better apply the anti-corrosion coating and obtain the ideal anti-corrosion effect.

Anticorrosive coatings are widely used in large industrial and mining enterprises, emerging marine equipment, modern transportation and important energy equipment, etc. The anticorrosive coating industry is also constantly developing and changing. According to the current anticorrosive coating market development trend and international and domestic demand, anticorrosive coatings still have broad development space in the future.

- High precision coating thickness gauge for used car

- Automotive paint protection films coating thickness gauge

- Plating Thickness Measuring Instrument for Detecting Anti-corrosion Coating

- Linshang LS220, LS191, LS160A– Necessary for Car Cover Inspection

- Coating Thickness Gauge for Second Hand Vehicle

- Zero Adjustment Step of Coating Thickness Gauge