Relationship between Gloss and Gaze and the Choice of Sheen Gloss Meter

Different glass materials and processing technologies will cause differences in its light transmission properties. In order to evaluate the appearance quality and performance of glass, the gloss, haze and clarity of glass can be tested. The following will bring you the glass gloss and haze test methods, interested friends may wish to take a look!

1. What is the relationship between glass gloss and haze?

Glass products will selectively reflect and selectively absorb light projected on it. Different materials have different ratios of reflected light and transmitted light, and their reflection directions are not the same. When measuring the same material glass at different angles, different values of gloss can be obtained. The gloss of glass here is a physical quantity that evaluates the ability of the surface to reflect light under a set of geometrically prescribed conditions, and is measured with a sheen gloss meter.

The haze is the ratio of the scattered light flux and the transmitted light flux that deviate from the direction of the incident light through the glass. The smaller the surface haze value, the better the surface properties of the material. Usually measured by a haze meter, it is not necessarily related to gloss.

However, for glass products of the same material, in order to control the product quality, it is necessary to measure its gloss and haze.

For example, AG glass, also known as anti-reflective glass or non-reflective glass, is a glass with extremely low reflectance to visible light. The visible light reflectance of ordinary glass is 4% -7%. When used as window glass, it often reflects the surrounding scenery and affects the real effect of the displayed items in the window. The anti-reflective glass has a visible light reflectance of less than 0.5%, which can eliminate the influence of glass surface reflection and improve the visible light transmittance of the glass, thereby improving the display effect of display items in the window. Therefore, AG glass tends to have a lower gloss, and at the same time, it also needs to have a lower haze value.

2. How to measure the gloss and haze of AG glass?

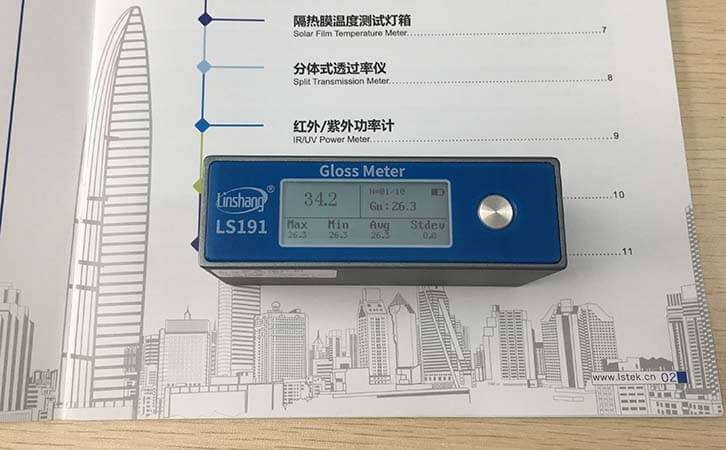

Generally speaking, the lower the gloss of AG glass, the larger the haze value, the more blurred the glass; the higher the gloss of AG glass, the smaller the haze value, the clearer the glass. In the actual production process, due to the influence of material and processing technology, in order to control the quality of AG glass, it is necessary to test its gloss and haze. Generally, gloss is measured with a sheen gloss meter, and haze is measured with a haze meter.

Sheen gloss meter usually has five angles of 20 degrees, 45 degrees, 60 degrees, 75 degrees, and 85 degrees. Generally speaking, low gloss is 85 degrees, high gloss is 20 degrees. According to the requirements of relevant gloss standards, different samples select a different angle to measure. Haze detection uses haze to measure the diffused and transmitted light fluxes to evaluate the degree of atomization of the material.

3. How to choose a sheen gloss meter?

Sheen gloss meter is used to measure the gloss of various materials, such as automotive paint, stone, plastic, paper and other products. It is used in many industries. In China, there are also many manufacturers of glossmeters. Various brands and models are known as national first-class accuracy. During the purchase process, it is easy to suffer from selection syndrome. In terms of the gloss instrument, which aspects need attention?

(1) The standard board of the sheen gloss meter must be well protected

The measurement of the sheen gloss meter must be based on the data of the gloss standard board as the reference standard. If the standard plate is inaccurate, the instrument must be inaccurate. Moreover, the gloss of the standard board is extremely vulnerable to contamination, so the standard board of the instrument must be well protected. Generally, a special base is used. The standard board is embedded in the base to avoid external pollution and scratches.

(2) Sheen gloss meter must have self-diagnostic function for standard board defacement

That is, if the standard board is dirty, the instrument can identify and prompt the user to clean the standard board. Otherwise the calibration will be wrong and all measurement data will be inaccurate.

(3) Gloss instrument needs temperature compensation function

The principle of the gloss instrument is to use a light source and a receiver to measure the reflected light flux on the surface of the material. If the ambient temperature changes after the instrument is adjusted, which causes the light source's luminous efficiency to change, the error of the light source's luminous efficiency change will be directly reflected in the measurement data. If there is a temperature compensation function, the change in luminous efficiency caused by temperature changes can be compensated to ensure that the luminous efficiency of the light source remains unchanged.

(4) Stability, consistency and accuracy of gloss instruments

These indicators are the core technology of an instrument. National first-level measurement accuracy, some manufacturers can only achieve by publicity or prototype, in mass production, it is difficult to achieve first-level accuracy. When purchasing a sheen gloss meter, if the seller promises to meet this standard, it can be sent to the metrology institute for confirmation after purchase.