Why UVLED Lamps will replace High-pressure Mercury Lamps | UV Radiometer Puck

Why do UVLED lamps replace high-pressure mercury lamps? What are the advantages of UVLED lamps compared to high-pressure mercury lamps? How should we choose UVLED lights and UV radiometer pucks? Let's find out together!

1. Why UVLED lamps replace high-pressure mercury lamps: No heat radiation

High-power LEDs do not emit infrared light. The surface temperature of the irradiated product will not rise above 5 degrees Celsius, and the traditional mercury lamp UV curing machine will generally raise the surface of the irradiated product by 60 to 90 degrees Celsius. In contrast, UVLED curing is more suitable for plastic materials, lens bonding, electronic products, fiber optic cables and other materials.

2. Why UVLED lamps replace high-pressure mercury lamps: No pollution

The mercury lamp bulb used in the traditional mercury lamp curing machine has mercury in it. Waste disposal and transportation are very troublesome. Improper treatment will cause serious pollution to the environment. The LED curing machine uses semiconductor light, which will not cause pollution to the environment. Therefore, the use of UVLED lamps is more environmentally friendly.

3. Why UVLED lamps replace high-pressure mercury lamps: High intensity

The high-power LED chip and special optical design make the ultraviolet light of the LED light more accurate and high intensity. At present, the maximum output of ultraviolet light can reach the intensity of 200,000 mW/m2. You can use a UV radiometer puck to accurately measure the ultraviolet light. Light intensity and energy. In addition, the high-power LED chip uses the latest optical technology and manufacturing process to achieve a more optimized high-intensity output and uniformity than the traditional mercury lamp irradiation method, which is almost twice the irradiation intensity of the traditional mercury lamp method, making the UV adhesive more Fast curing, shortening production time and greatly improving production efficiency.

4. Why UVLED lamps replace high-pressure mercury lamps: Low power consumption

The luminous efficiency of UV LEDs is more than ten times that of mercury lamps. At the same time, no matter whether the mercury lamp is effectively irradiated or not, it needs to be continuously lit to work, and the power is always in a state of consumption. The UV LED method consumes power only when irradiated, and the power consumption is almost zero during standby.

It can be seen that the electricity cost saved for each LED curing machine can reach thousands of yuan each year. Not only that, by saving electricity, each LED curing machine can indirectly reduce carbon dioxide emissions by 1.4 tons per year, which is equivalent to the annual exhaust of a car. However, UV radiometer pucks measures the intensity and energy of ultraviolet light.

5. Why UVLED lamps replace high-pressure mercury lamps: Simple installation and space saving

The volume of the LED curing machine is only one-fifth that of the conventional curing machine, and the installation of the equipment is simpler, reducing the area occupied by the production site.

6. How to choose UVLED lamp and UV radiometer puck?

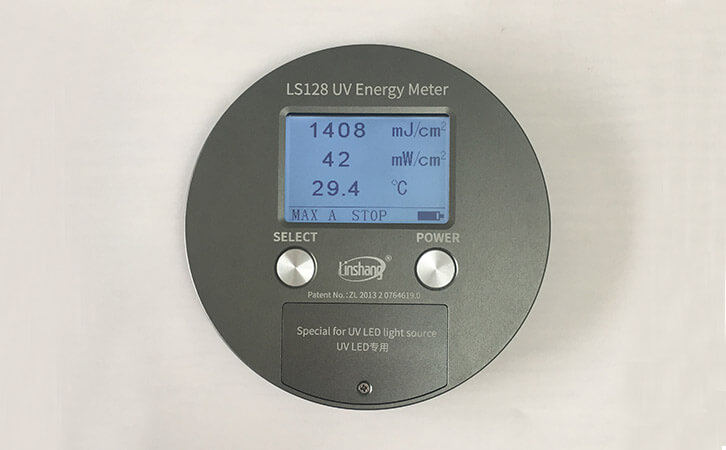

The inspection and maintenance of UVLED lamp are one of the main conditions to ensure the maximum efficiency of the UV curing system! We can use the LS128 UV radiometer puck when testing UVLED lamps. The spectral response range of the Linshang LS128 UV LED energy meter is 340nm-420 nm, so it is no problem to test any band in the spectral response range, and the consistency and stability of the instrument are very good. Using the Linshang LS128 UV radiometer puck is an indispensable tool for selecting UVLED lamps, and it is also the best partner for measuring the UV light intensity and energy of UVLED lamps in the later stage!