Tips on Buying Paint Thickness Gauge

1.How accurate should the high precision paint thickness gauge be?

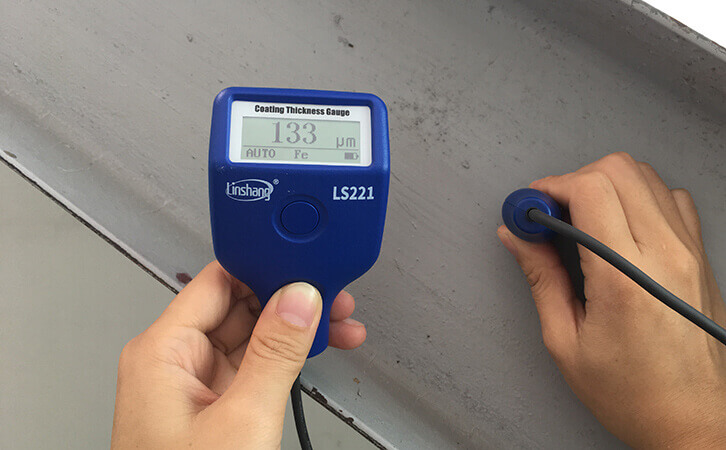

The key to choosing a suitable paint thickness gauge is the accuracy. In different measuring ranges,the accuracy of paint thickness gauges is moving towards higher and higher directions.This is reflected in the price of the paint thickness gauge , the higher the accuracy,the higher the cost.Linshang paint thickness gauge is a high-precision paint thickness gauge .The instrument uses an advanced ruby digital probe,which is resistant to wear.It also has a temperature compensation function, which can be used at minus 20 degrees .The instrument insure measurement accuracy at different temperatures.Widely used in steel structure coating,automobile,coating and other fields.As a professional paint thickness gauge manufacturer,Linshang Technology is committed to improving the using experience of customers while providing high-quality products. The thickness of the Linshang paint thickness gauge is as high as ≤ ± (3% of reading + 2μm),but the price is not expensive to be unacceptable.Compared to German QNix, which cost several thousand RMB and other cost-effective instruments,the instrument only costs $148!The coating process and other factors affect the variability of the coating thickness on a particular surface. In addition,the use of paint thickness gauges will also affect the accuracy of the data.

2.How to test the accuracy of paint thickness gauge ?

The basic indicator of the paint thickness gaugeperformance is the accuracy of the readings taken by the instrument.That is the difference between the reading and the actual coating thickness.In order to test the accuracy of paint thickness gauges,it is important to have traceable coating thickness standards.Zero the instrument on an uncoated, smooth substrate and set to a known or near maximum thickness standard. Then measure the intermediate thickness standard and compare the reading with the actual thickness of the standard.Error is the difference between the reading and the standard value expressed as a percentage.The accuracy of the instruments is usually checked by a third-party agency,the National Metrology Institute. Linshang paint thickness gauge can pass the inspection of the Chinese National Metrology Institute.

3.Adjustment of paint thickness gauge

Material differences,shapes and surface finishes will more or less affect the readings of the paint thickness gauge.Sudden changes in temperature can also change the conditions under which the instrument operates.We should adjust the paint thickness gauge to reduce the impact of the external environment.The Linshang paint thickness gauge is equipped with a temperature compensation function to ensure that the instrument is not affected by the drastic temperature change during operation to ensure the accuracy of the instrument.The instrument uses a large number of standard plates for debugging during the research and development process.In the process of use,it only needs no calibration just zero adjustment,which brings great convenience to customers.Linshang paint thickness gauge is easy to operate and has high accuracy,which is the best choice for customers!

- Application of gloss meter in automotive industry

- Precautions for Use of Coating Thickness Gauge

- What is the Relationship between Surface Gloss and Color Difference?

- What is the Difference between the LS117 Densitometer and the Spectrophotometer?

- Window Tint Meter Measure VLT of Window Film

- Will the Auto Paint Meter Damage the Car Paint?