Factors Affecting the Eddy Current Thickness Gauge Accuracy

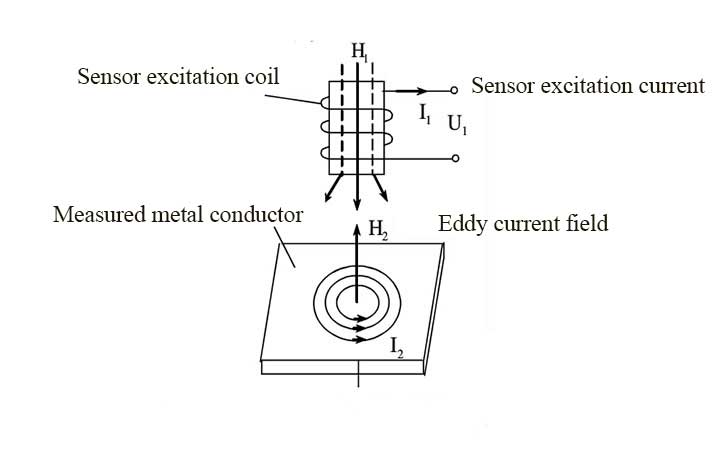

The eddy current thickness gauge is a coating thickness gauge using the eddy current principle. So what is eddy current thickness gauge and how does a eddy current thickness gauge work?

1.What is the eddy current thickness gauge:

The eddy current thickness gauge is simply a coating thickness gauge with a high frequency electromagnetic field. When the probe is in contact with a conductor containing a cover layer, the electromagnetic field creates an eddy current in the cover layer. The amplitude and phase of the eddy current is a function of the non-conductive layer covering layer present between the cover layer and the probe. The thickness of the paint film is calculated by a function.

2.What are the factors that affect the accuracy of the eddy current thickness gauge?

1)Electrical properties of the metal substrate

The thickness of the paint film measured by the eddy current thickness gauge is affected by the electrical conductivity of the metal.The electrical conductivity has a great relationship with the heat treatment and composition of the tested material.

2)Metal substrate thickness

Most eddy current thickness gauges have a critical value for the base metal, which depends on both the conductivity of the metal matrix and the frequency of measurement of the probe. Generally,when the measurement frequency is constant,the higher the conductivity of the metal substrate,the smaller the critical thickness value.When the metal matrix is constant, the higher the measurement frequency, the smaller the critical value of the base metal.

3)Edge effect

Under normal circumstances,the eddy current thickness gauge has discontinuous sensitivity to the tested object surface.It is unreliable when the instrument is close to the edge or corner. Unless the instrument is specifically calibrated for this type of measurement.

4)Curvature

Curvature varies greatly depending on the type of instrument.Simply speaking, curvature affects the reliability of the measurement data on the curved surface of the instrument.Unless the instrument is specifically calibrated for this type of measurement.

5)Temperature of the probe

A typical eddy current thickness gauge affects the performance of the probe when the temperature changes greatly.It is necessary to use the probe measurement under substantially the same conditions as the calibration temperature.

6)Placement of the probe

The measurement method of the probe directly affects the measurement data. When using an eddy current thickness gauge, we should always keep the measuring point of the probe perpendicular to the tested surface.

3.Linshangeddy current thickness gauge

1)The design principle of Linshang eddy current thickness gauge adopts both eddy current thickness measurement method and magnetic thickness measurement method. At the beginning of the design, the above factors affecting the accuracy of the eddy current thickness gauge are considered.The Linshang eddy current thickness gauge has temperature compensation function and the working temperature is from 0 °C to 50 °C. The storage temperature range is from -20 °C to 60 degree.Therefore, the performance of the probe is not affected by the temperature change.

2)The instrument has a signal terminal digitization function to ensure the stability of the eddy current thickness gauge sensor signal.

3)Linshang eddy current thickness gauge uses a ruby probe which is corrosion-resistant and wear-resistant.

- High precision coating thickness gauge for used car

- Automotive paint protection films coating thickness gauge

- Plating Thickness Measuring Instrument for Detecting Anti-corrosion Coating

- Linshang LS220, LS191, LS160A– Necessary for Car Cover Inspection

- Coating Thickness Gauge for Second Hand Vehicle

- Zero Adjustment Step of Coating Thickness Gauge