Eddy Current Thickness Gauge Principles and Characteristics

Common coating thickness gauges are developed for measuring coating thickness. Common used coating thickness measuring principles include Hall Effect, eddy current , ultrasonic, etc.

Magnetic(Hall effect) coating thickness gauge can non-destructively measure the coating thickness on ferrous metal substrate.

The eddy current thickness gauge can non-destructively measure the non-conductive coating thickness on non-ferrous metal substrates.

Ultrasonic thickness gauge can non-destructively measure the coating thickness on wood and concrete.

1. Eddy current principles for coating thickness measurement

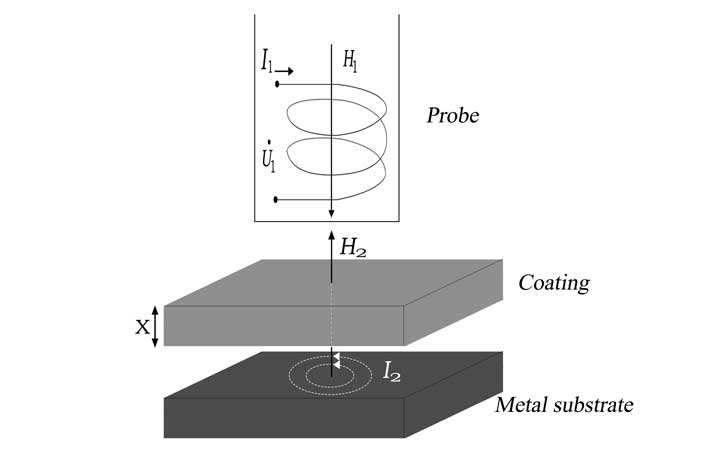

The coil core in the eddy current coating thickness gauge probe is usually made of a high-frequency material such as platinum-nickel alloy, which generates a high-frequency electromagnetic field in the coil by the current. After contacting of the conductor (metal substrate) at the probe and the bottom, eddy currents are formed on the metal substrate. The closer the probe is to the conductor (metal substrate),the larger the eddy current and vice versa. This eddy current will have a feedback effect on the coils in the probe. The magnitude of the feedback action can represent the distance between the probe and the conductor (metal substrate),that is,the non-conductive coating thickness on the conductive metal substrate.

2.Characteristics of eddy current coating thickness gauge

The eddy current thickness measurement method can theoretically measure the thickness of the coating on the magnetic metal substrate.The calibrated instrument can measure the coating thickness with certain conductivity,but the requirements of this type of test on the substrate and the cover layer are very high,so it is not recommended.If it is necessary to measure the thickness of the coating on the magnetic metal,it is recommended to use the instrument of magnetic thickness measurement principle. The instrument using a single eddy current thickness measurement method has narrow measurement range, so gradually coating thickness gauges using both principles at the same time appear.Linshang coating thickness gauge use both magnetic and eddy current measurement principles which can be used for the measurement of non-ferromagnetic coatings on ferromagnetic metal substrates and non-conductive coatings on non-magnetic metal substrates.

| Measuring principles |

Substrate | Coating | Examples | Yes/No |

| Magnetic | Ferromagnetic materials:Iron, cobalt, nickel, thorium |

Non-ferromagnetic metal | 1.Galvanized iron 2.Iron copper plating |

√ |

| Non-metal materials | 1.Iron spray paint 2.Iron spray powder coating |

√ | ||

| Ferromagnetic materialIron, cobalt, nickel and thorium |

Iron nickel plating | × | ||

| Eddy current | Non-ferromagnetic metal: Copper, aluminum,magnesium, zinc, etc. |

Non-conductive material | 1. Anodized aluminum surface 2. Copper spray paint |

√ |

3. Best eddy current coating thickness gauge

Linshang coating thickness gauge uses both eddy current thickness measurement method and magnetic thickness measurement method to cover the measurement range of the eddy current coating thickness gauge and the magnetic thickness gauge.The common non-magnetic metal is aluminum and the common magnetic metal is iron.Therefore,this dual-principal instrument is used to measure the coating thickness on ferrous and non-ferrous substrates.

For more information about the aluminum alloy anodized layer thickness measurement using coating thickness gauge, please read "Coating Thickness Gauge Test Aluminum Alloy Anodized Layer Thickness".

- High precision coating thickness gauge for used car

- Automotive paint protection films coating thickness gauge

- Plating Thickness Measuring Instrument for Detecting Anti-corrosion Coating

- Linshang LS220, LS191, LS160A– Necessary for Car Cover Inspection

- Coating Thickness Gauge for Second Hand Vehicle

- Zero Adjustment Step of Coating Thickness Gauge