Marble Gloss Meter

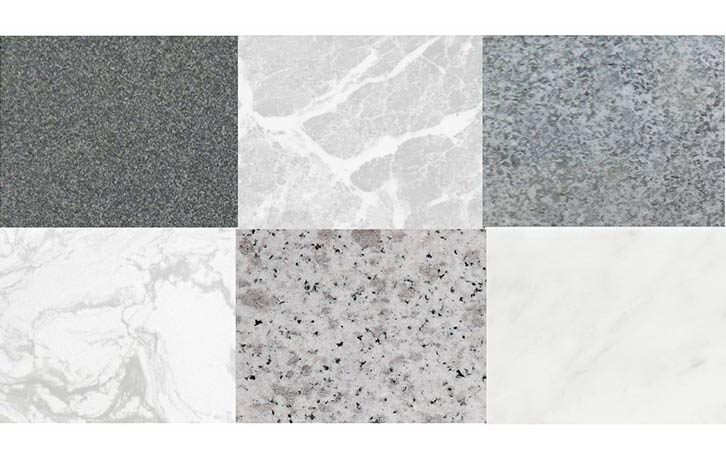

Stone is mainly divided into two major categories of artificial stone and natural stone. Natural stone is divided into marble and granite. Artificial stone is a general term for artificial marble and artificial granite. The bright color of artificial stone is higher than that of natural stone.

1. Stone gloss

The stone gloss specifically refers to the degree of reflection of its surface on visible light. The stone we usually use for decoration can be mainly divided into mirror plate and veneer plate. The stone gloss is actually a physical quantity, a physical evaluation of the light reflection ability under specific geometric conditions, which is what we usually call specular gloss. The specular gloss is determined by the microstructure of the stone surface and the refractive index of the stone composition.

2. Factors affecting the stone gloss

The factors affecting the stone gloss are mainly human factors and natural factors.

Natural factors:

The stone gloss is mainly determined by the refractive index of the composition of stone minerals. The higher the refractive index of the mineral under other conditions, the higher the stone gloss.

The microstructure of the stone surface will also affect the stone gloss. The less the surface defects the stone surface, the higher the gloss and the smoother the surface.

Human Factors:

Polishing the stone surface, the smoother the polishing of the stone surface, the higher the stone gloss. If the roughness is rough, the smoothness will be lower.

3. Measuring the stone gloss with a marble gloss meter

Classification of stone gloss

Due to the difference between the chemical composition of the stone, the same grade of stone gloss value is also different. Good stone according to different chemical composition, the gloss value can be mainly divided into three categories of 60, 80, 90GU.

How does the marble gloss meter measure the stone gloss?

The light source emits a beam of light perpendicular to the stone plane (20±0.1) degree, (60±0.1) degree (85±0.1) degree and the incident aperture is generally 18 mm. The mirror image of the receiver axis is within ±0.1 degree of the axis of the incident ray and then reflects the light through the standard board to the concentrating spot. The photocell converts the light energy into electrical energy after being received by the light energy. Then the data is displayed on the interface. This marble gloss meter completes a simple stone gloss measurement.

4. National standard of marble gloss meter

"Building Materials - Method for Measuring Mirror Gloss" provides:

Various architectural materials are measured using 60 degree geometry for mirror gloss.

When the 60 degree gloss meter is used to measure the gloss value of the image which is greater than 70 degree, a 20 degree marble gloss meter can be used to improve the resolution.

When the gloss value measured by the 60 degree marble gloss meteris less than 10 gloss units, an 85 degree marble gloss meter can be used to improve the resolution.

The ratio of the reflected light flux from the mirror image direction of the object to the reflected light flux in the mirror image direction of the 1.567 refractive index under the conditions of the specified light source and acceptance angle.