Gloss Testing Equipment Angle Selection

I. How to measure gloss accurately?

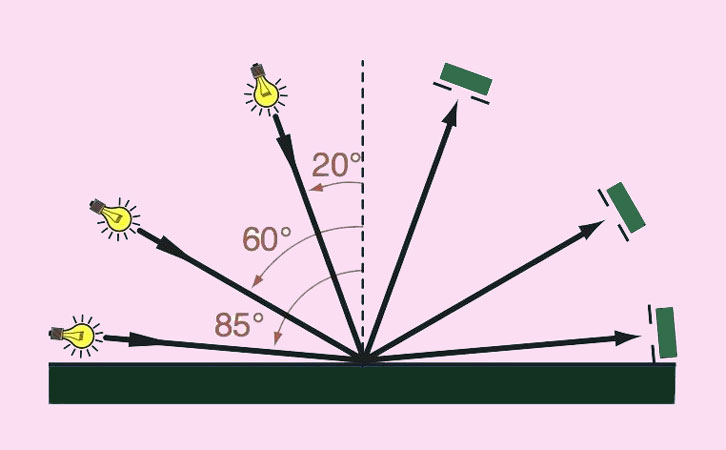

Gloss is a visual property of an object. The more light that can be reflected on the object surface, the higher the gloss. It is entirely up to the experience to judge the object surface gloss with the naked eye. In order to truly assess the gloss size and uniformity, a professional gloss testing equipment is required for measurement. The gloss measured by the instrument is related to the incident angle of light. So when testing the same material, the data will be different when the gloss testing equipment angle is different.

II. Different gloss testing angles

| Gloss measurement angles | Gloss | Tested material |

| 20° | High gloss | Metal, glazed paper,etc |

| 45° | Medium gloss | Ceramics |

| 60° | Medium and low gloss | Almost everything |

| 75° | Low gloss | Paper |

| 80° | Low gloss | leather, wood,etc. |

1. 20 degrees - high gloss

An acute angle of 20 degrees can increase the resolution of the surface gloss data of a high gloss material. If the gloss is greater than 70 GU using a 60 degree gloss tester, the surface gloss of such a material can be referred to as high gloss. The 20 degree gloss testing equipment is suitable for metal, high gloss paper and other materials.

2. 45 degrees

There are fewer 45-degree gloss testing equipment on the market, mainly used to test the gloss of materials such as ceramics and films.

3. 60 degrees - universal type

60 degree is the most versatile gloss testing equipment angle choice. Any gloss material can be measured with a 60 degree gloss testing equipment. The high gloss, medium gloss and low gloss are also classified based on the test data of 60 degree gloss testing equipment.

Why are there other angles of gloss? This is because the 85 degree or 20 degree gloss testing equipment can be used to obtain higher resolution measurements when testing low gloss and high gloss. But the current standard 60 degree angle gloss testing equipment is greatly improved and can be applied to the testing of all materials.

4. 75 degrees

The 75-degree paper gloss meter is mainly used for paper surface gloss testing of paper and vinyl production.

5. 85 degrees - low gloss

The 85 degree gloss testing equipment is suitable for measuring the gloss of some textured or uneven surface materials. If the gloss is less than 10 GU using a 60 degree gloss tester, the surface gloss of such a material commonly referred to as low gloss. The 85 degree gloss testing equipment is used to test some low-gloss, or matte surfaces, as well as some high-diffuse reflective material surface gloss.

III. Why do we choose 60 degree gloss testing equipment?

This is because the 85 degree or 20 degree gloss testing equipment can be used to obtain higher resolution measurements when testing low gloss and high gloss. But the current standard 60 degree angle gloss testing equipment is greatly improved and can be applied to the testing of all materials.

In fact, 45 degree and 75 degree are only suitable for some special industries, the application is not very wide. But these two gloss measurement angles are rarely used. When we choose the gloss testing equipment angle, we can consider 20 degree, 60 degree and 85 degree. 60 degree gloss testing equipment is the most commonly used one, so a high-precision 60-degree gloss testing equipment can meet all needs.