How do Gloss tester Work and Its Application?

The gloss tester is widely used in industrial applications, but people do not know much about the gloss detection, measurement principles, standards and the maintenance of the instrument. This article mainly explains the gloss tester from the above aspects.

I. Gloss detection

1.What is gloss?

Gloss refers to the physical quantity that evaluates the ability of a material's surface to reflect light under a set of geometrically specified conditions. Gloss is the characteristic of the material surface. The gloss mainly depends on the specular reflection ability of the material surface. According to the characteristics of gloss, we can divide gloss into several categories and what we generally refer to as gloss refers to specular gloss.

2.How to measure gloss?

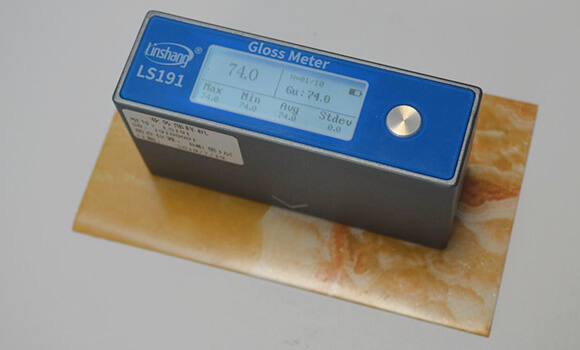

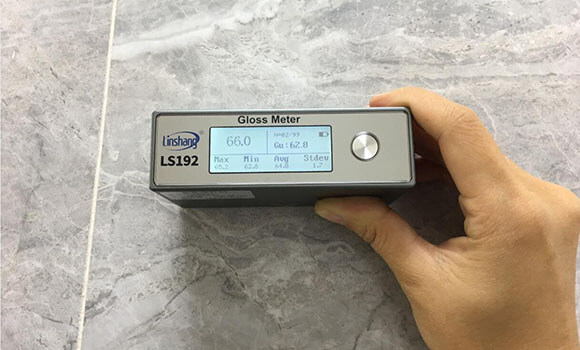

We can use the naked eye to judge the glossiness of the object surface, but our naked eye can only roughly judge the gloss degree and cannot accurately give the data. We need to use a gloss tester. It is very convenient to measure the gloss value by the gloss tester, not only the measurement data is accurate but also the gloss uniformity can be judged.

3.Why is it important to detect gloss?

(1) Good gloss attract consumers

The product gloss is the most intuitive visual experience for consumers. Its status and color are equally important. For example, the highly reflective car panel of the car will give people a dazzling and cool feeling whether in the light or in the sunlight. Stylish furniture exuding a faint luster will give people a sense of high class. Therefore, the good product gloss will be enough to attract consumers' attention. Therefore, the manufacturer should control the gloss and use a gloss tester to detect the product gloss.

(2) Good gloss help judge product quality

We know that the gloss of the object surface is affected by many factors, so we can judge the quality of the material by using the gloss tester. For example, the base material of the paint, the number and type of materials used and the polishing after grinding will all affect the object gloss. Therefore, it is very important to detect the product gloss. We can conduct uninterrupted gloss testing through different batches of products or different products to judge product quality.

II. Gloss tester principle and standard

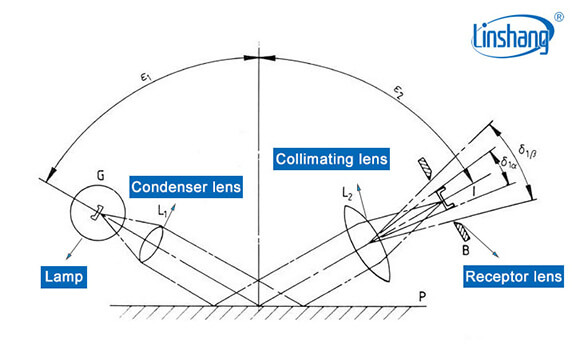

1. Gloss tester measuring principle

The measurement principle of the gloss tester is mainly that the light source emits a beam of light through the lens to reach the measured surface. The measured surface reflects the light to another lens and the other lens converges the reflected light in the photovoltaic cell. Then the photocell converts the optical signal into an electrical signal and sends it to the circuit for processing. The gloss tester will display the measurement results we have seen.

2. Gloss tester standard

We know that the gloss tester can be divided into single-angle and multi-angle glossiness measuring instruments. Generally, the gloss tester with a 60-degree angle is used for medium gloss measurement and the high-angle gloss tester is used for low gloss measurement. High-angle gloss tester can test low gloss objects.

The 60 degree angle gloss tester is mainly used to measure medium gloss products such as copper cardboard, paint, ink, etc. The Chinese national reference standards are: ISO-2813, DIN-6750, ASTM-D2457, ASTM-C584, ASTM-D523, GB 9754, GB 8807, GB 9966

ational standards that Linshang gloss tester meets:

"GBT 9754-2007 Paints and varnishes-Determination of specular gloss of non-metallic paint films at 20°,60°, 85°"

"JJG 696-2002 Verification Regulation of Specular Gloss Meters and Gloss Plates "

3. Linshang gloss tester parameters

● Measuring range: 0-200GU

● The minimum size of the measured items: 28mm (length) * 14mm (width)

● Measuring light spot: 9 * 15mm

● The minimum size of the measured items: 28mm (length) * 14mm (width)

● Measuring range: 0-1000GU

III. Gloss tester application

It can be seen from the above that there are many types of gloss testers: 20-degree angle, 45-degree angle, 60-degree angle and 85-degree angle. Among these four angles, the 60-degree gloss tester is the most widely used. It can be widely used in paint, stone, stainless steel, hardware, ceramics, wood products, plastics, etc.

For example, paint can be used for car paint, door and window paint, pipeline paint, etc. Stone can be used for granite, marble, terrazzo, etc. Metals can be used to measure stainless steel, coatings, alloys, etc.

IV. Gloss tester operation and maintenance

(1) How to use Linshang gloss tester?

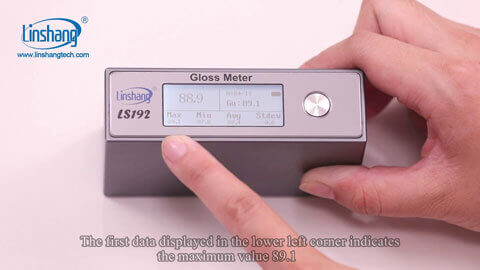

Power-on self-test. After the self-test shows OK, the gloss tester enters the measurement state. The instrument displays the measurement result immediately after placing the instrument on the measured object. There is no need to press buttons during the whole measurement process.

After the power-on self-test, the measurement data can be cleared. During the measurement process, press the power button to record the measurement data. The specific operation method can refer to the following video:

(2) Linshang gloss tester maintenance

The base should be stored in a clean place after being removed from the host to avoid the standard board from being damaged.

The gloss tester and standard board should be cleaned before storage and use. Use a clean special lens cloth to remove contaminants. The surface of the standard board is very precise, ensure that the lens cloth does not have any fine particles, otherwise the standard board will be damaged.

Do not insert any objects into the instrument to clean it, as this will damage the instrument and affect the measurement accuracy and operation safety.

If the gloss tester is not used for more than half a year, regular charging is required to prevent the battery from excessive discharge damage.

Avoid contact with corrosive materials and keep away from high temperature and high humidity environment.

Please put it in a special package after shutdown and keep it in a safe place.

It is recommended that the verification period be one year and the company provides calibration services.