How to Measure Gloss using a Gloss Meter?

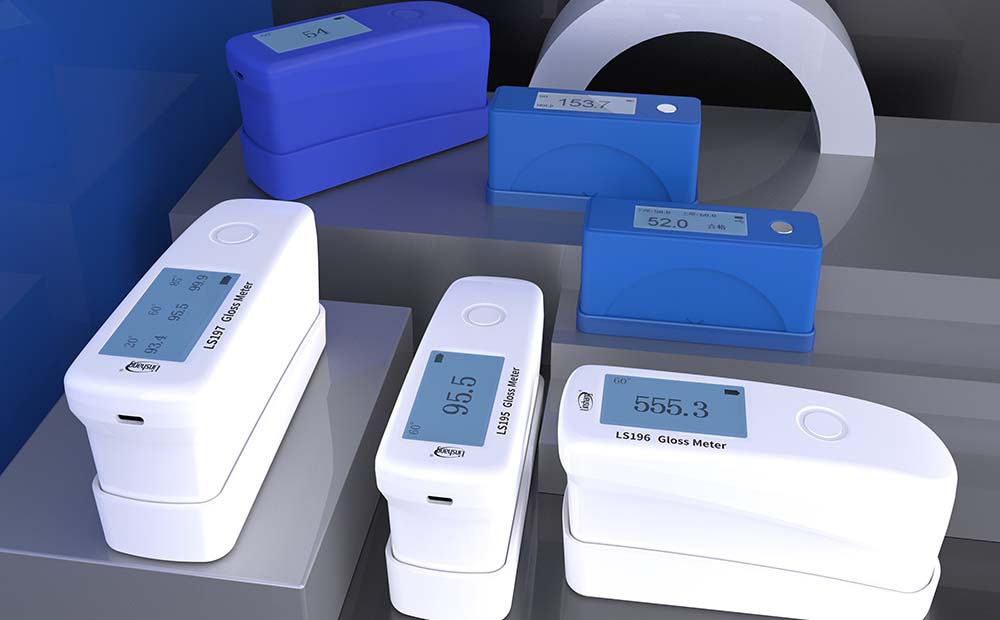

Gloss is a physical quantity that evaluates the ability of the material surface to reflect light under the specified light source and receiver opening angle conditions. The gloss we usually refer to refers to "specular gloss", and the gloss meter is an instrument used to measure the gloss of various materials, such as automotive paint, ceramics, inks, plastics, marble, paper, leather and other materials. It is used in many industries in industrial and civil use.

The gloss meter is an instrument used to determine the reflective ability of the surface of the object to light. It has no unit itself, and everyone uses GU to express it. It is mostly used in quality inspection, and quality control is carried out by testing the size and uniformity of gloss.

How to measure Gloss?

Gloss is measured by shinning a known amount of light at a surface and quantifying the reflectance. The specular reflectance is measured using a gloss meter. Different surfaces require different reflection angles.

When the light source and receiver are at a fixed angle, the light intensity (luminous flux) reflected by the light beam on the sample is divided by the light intensity reflected by the standard plate, and then multiplied by the gloss value of the standard plate, which is the gloss of the sample.

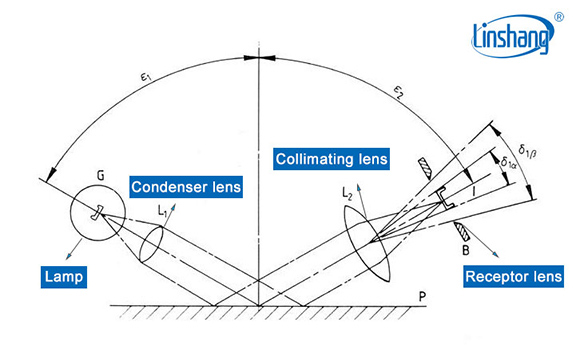

The construction of a Gloss meter

A typical gloss meter consists of a fixed mechanical assembly consisting of a standardized light source that projects a parallel beam of light onto the test surface to be measured, and a filter detector that receives the light reflected from the surface.The instrument adopts D65 light source, and the receiver spectral response curve conforms to the spectral visual function V(λ), which ensures more accurate measurement of colored objects.

Choosing the Correct Angle for Gloss Measurement

The specular reflection ability of low-gloss materials is weak. If an instrument with an angle of 20 degrees is used for measurement, the luminous flux received by the detector is very weak after being reflected by the material surface, and the data is very small compared with the light reflected by black glass. Therefore, when measuring low-gloss materials with different gloss levels, the measured value changes very little, and the resolution is not enough to distinguish subtle differences in material gloss. Similarly, if a high-gloss material is measured at an angle of 85 degrees, the resolution is not sufficient to distinguish the difference in gloss of the material.

Therefore, it is generally recommended to choose an angle of 85 degrees for low-gloss materials, and a 20-degree angle for high-gloss materials. Other medium-gloss materials can choose 60-degree angle instruments. The 60-degree angle gloss meter performs better when measuring the surface of high-gloss and low-gloss materials.

High-gloss material, that is, the specular gloss of 60° is higher than 70GU. High-gloss ink, paint, plastic, stone, etc. are the principal materials that the 20° gloss meter is used for.

Low-gloss material, that is, the 60° specular gloss is less than 10GU. Low-gloss paints, camouflage coatings, and other low-gloss materials are the major uses for the 85° gloss meter.

The medium-gloss coated paper, marble, ceramics, paint, etc. are the major items measured with the 60° gloss meter.

Gloss meter operation

Next, take Linshang's LS197 gloss meter as an example to introduce the operation method of the gloss meter.

1. Select QC mode/Normal mode

In the off state, press and hold the power button to enter the setting interface, short press the power button to select, and long press the power button to confirm. After selecting the language interface, enter the interface for selecting the measurement mode. Press the power button to confirm.

In QC mode, it is necessary to set the upper and lower limit values through the PC software connected to the computer, and the QC mode will automatically determine whether the glossiness of the measured object is qualified or not based on the measured gloss value.

In the normal mode, you only need to put it on and measure it, and the data will appear immediately.

2. Choose an angle match

After the measurement mode is selected, enter the angle selection interface. The LS197 gloss meter has 7 angle combinations. According to the measurement needs, short press the power button to select the required angle, and long press to confirm.

3. Calibration

After the setting is completed, it will enter the calibration interface. Before calibration, please clean the standard plate with the cleaning cloth provided by Linshang, then cover the bottom cover of the instrument, and short press the power button to calibrate.

4. Measurement

When selecting the QC mode, put the gloss meter on the surface of the object to be tested and press the power button shortly, and the instrument will display the gloss value.

When the normal mode is selected, put the gloss meter on the surface of the object to be measured, and the gloss value will be displayed immediately. Short press the power button to lock the measured gloss value, and then short press to resume measurement.

Precautions for using gloss meter

1.Standard Plate Cleaning

The cleanliness requirements of the standard board are very high, and ordinary paper towels and cloths cannot meet the cleanliness requirements of the standard board. The standard plate must be wiped with a special cleaning cloth, or a good lens paper can be used.

2.Environments with sharp temperature changes require calibration

From a place with lower temperature to a place with higher temperature (such as outdoor to indoor in winter), or from high temperature to low temperature environment, please leave it for a period of time before measuring. One is because the surface of the optical lens will be fogged when it goes from a place with low temperature to a place with high temperature, and the other is because of the temperature compensation function of the instrument, when the internal temperature of the instrument is basically balanced with the ambient temperature, the compensation effect is the best.

3.The sample to be tested must be larger than the area of the measuring spot and be flat on the test surface

When measuring, the surface of the tested sample must cover the measuring hole of the instrument. The minimum size of the measured object of the LS197 gloss meter is 57mm*10mm, and the tested sample must be larger than the area of the measuring spot and be flat on the test surface.

4.Avoid the influence of external light

It is necessary to avoid the influence of external light as much as possible. When stray light enters the instrument through the contact surface between the instrument and the sample to be measured, the stray light will affect the measurement accuracy of the instrument.