Leeb Hardness Tester and Webster Hardness Tester

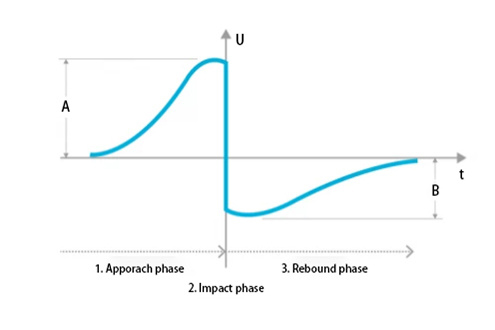

Based on the principle of Leeb hardness measurement, the Leeb Hardness Tester, otherwise called as Leeb Rebound Hardness Tester, is considered as one of the most commonly used tools to test the hardness of the metal. It is a type of non-destructive testing tool used to inspect large sized workpieces weighing above 5 kg. Besides the hardness, it also measures the strength of materials.

Linshang Leeb Hardness Tester is suitable for testing various metal materials such as alloy steel, stainless steel, gray cast iron, ductile iron, etc.

LS256 Ultrasonic Hardness Tester

Integrated design + Two probes

Small indentation, non-destructive measurement

Easy operation for measuring flat, small, or irregular parts

High precision, good repeatability

LS251D Leeb Hardness Tester

Suitable for measuring iron, copper, steel and other metal materials

Using advanced digital probe technology, test accurately

The probe has a built-in direction sensor to automatically compensate the measurement errors in different impact directions

A variety of hardness scales switchable, eliminating the tedious manual check table

LS252D Leeb Hardness Tester

Pen-type Leeb hardness tester Dual-coil technology Extraordinary accuracy:±6HL Perfect for quick and reliable testing on site

LS252DC Leeb Hardness Tester

Integrated handheld hardness tester

Spring loaded with a special loading stick

Dual-coil technology

Extraordinary accuracy:±6HL

LS252DL Leeb Hardness Tester

Adopt impact device DL

Suitable for hardness measurement in confined spaces such as grooves and gears

Advanced dual coil technology for good repeatability and high accuracy

LS252C Leeb Hardness Tester

Adopt Impact device C

Ideal for testing the hardness of surface hardening layers and parts with small masses or thin thicknesses

Dual coil technology for good measurement accuracy and repeatability

LS253 Multi-probe Leeb Hardness Tester

1.Equipped with D\DL\DC\C four different impact devices

2.Support Bluetooth APP, massive data storage

3.Optional Bluetooth wireless printer, direct printing of measurement data

4.Double coil and digital probe, accurate measurement

LS255 Webster Hardness Tester

1. Digital display design, 0.1HWA high resolution

2. Automatic data locking, easy to read

3. Providing a variety of hardness scales to switch

4. No-disassembly reference calibration and hardness calibration technology

5. High precision, pass authoritative metrology inspection