LS252DL Leeb Hardness Tester

Impact device DL is suitable for hardness measurement in confined spaces

Dual coil technology ensures more accurate measurements

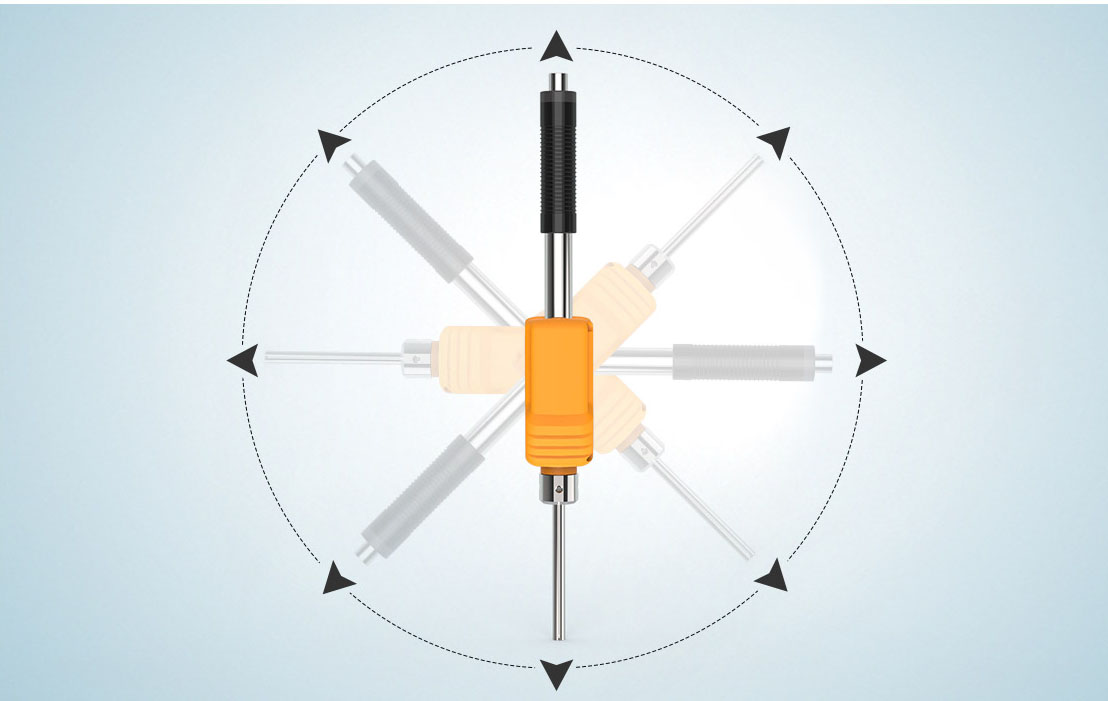

Probe with orientation sensor for error-free measurement at all angles

Multiple measurement materials can be switched

LS252DL Leeb Hardness Tester Advantage Video

The LS252DL is an all-in-one hardness tester that measures hardness according to the Leeb hardness measurement principle and can be used for hardness measurements on a wide range of metals. The instrument uses impact device DL and is suitable for testing in grooves or on gears where space is tight. It uses advanced dual coil technology for good repeatability and high accuracy. The probe with orientation sensor compensates for measurement errors in different impact directions automatically. The system has various hardness scales, which can be interchanged between Richter (HL), Vickers (HV), Brinell (HB), Shore (HS), Rockwell (HRA), Rockwell (HRB) and Rockwell (HRC) to avoid tedious manual calculations.

Application

The instrument uses the impact device DL with a wide choice of built-in metal materials to suit the needs of different metal hardness tests.

Parameters

| Parameters | values |

|---|---|

| Probe | Impact device DL |

| Hardness Scales | HL, HV, HB, HS, HRA, HRB, HRC |

| Measurement Range | HLD: (170-960); HV(194-976); HB(188-651); HRC(17.6-68.5); HS(29.54-99.5); HRB(91.5-100); HRA(60-85.8) |

| Resolution | 1HL |

| Accuracy | ±12 HL, ±6 HL typical |

| Repeatability | 6HL (factory standard) |

| Display | 128 * 64 dot matrix OLED |

| Power Supply | Rechargeable lithium battery 3.7V@250mAh, full charge for over 5000 continuous measurements |

| Charging Port | USB(Type-C) |

| Size | 203*34*24 mm |

| Weight | 78g |

| Working Temperature Range | -10~50℃,0~85%RH(no condensation) |

| Storage Temperature Range | -10~60℃,0~85%RH(no condensation) |

Features

Impact device DL

It is suitable for testing the hardness of metals in tight spaces such as recesses

Cutting-edge dual-coil technology

The technology brings the tester extraordinary measurement accuracy and good repeatability

Direction sensor inside the probe will compensate the measurement errors in different impact directions automatically

The instrument can measure at any angles. Featuring a built-in direction sensor, the probe can automatically compensate the measurement errors in different impact directions. Multi-angle measurement is easy

Impact device is made of Tungsten carbide

Impact device DL is partly made of Tungsten carbide, and its hardness is almost equal to the diamond

Conversions to different hardness scales

LS252DL hardness tester provides a variety of hardness scales, which can be converted between Leeb (HL), Vickers (HV), Brinell (HB), Shore (HS) and Rockwell (HRA/HRB/HRC)

Capable of measuring a wide range of metal materials

With 10 metal materials choices, including steel, alloy tool steel, stainless steel and grey cast iron, the instrument can be used in a wide range of applications and industries to meet the demands of everyday work

USB port is used to charge to battery

Using rechargeable lithium battery, the battery can be charged simply from USB port

Dynamic hibernation algorithm, Long life span

The instrument uses a dynamic hibernation algorithm to greatly extend the standby time and is equipped with a large-capacity lithium battery for long-lasting operation

Customer re-calibration allowed

Users can calibrate the standard parts to eliminate the error

Qualifications and standards

The hardness tester conforms to the following standards:

Operation

Loading: Push down the loading sleeve of the probe to lock the impact body.

Positioning: Press the probe firmly against the surface of the object to be measured and keep it still.

Measurement: Press the release button on the top of the probe to measure the hardness of the object.

Cautious

When measuring, the distance between any two indentations should not be less than 3mm, and the distance between the center of the indentation and the edge of the object to be measured should not be less than 5mm.

After use, the impact body should be loosened.

The use of various lubricants is strictly prohibited in the impact device.

Packing

| No. | Product Name | Quantity | Unit |

|---|---|---|---|

| 1 | Leeb Hardness Tester | 1 | Set |

| 2 | Locating Sleeve | 1 | pcs |

| 3 | USB data cable | 1 | pcs |

| 4 | Nylon Brush | 1 | pcs |

| 5 | User Manual | 1 | pcs |

| 6 | Calibration Report | 1 | pcs |

| 7 | Certificate / Warranty card | 1 | pcs |

FAQ

-

What is the thinnest thickness a durometer can measure and what is the thinnest thickness after coupling?

Leeb hardness tester is only suitable for large and heavy workpieces, small and thin parts must be coupled to a solid support for testing; DL-type impact device is measured by the minimum mass of 5kg, the minimum thickness of 25mm, if the weight or thickness does not meet the requirements, must be coupled to a solid support for testing, coupled to the minimum thickness of the measured object is 3mm.

Videos

Leeb hardness tester measures the hardness of gear tooth surfaces

LS252DL(Impact device DL) Leeb Hardness Tester Features and Operation

Leeb hardness tester measures the hardness of mold steel

Leeb hardness tester can achieve 360° all-round measurement

Leeb hardness tester repeatability demonstration

How to calibrate Linshang Leeb hardness tester

Small mass workpiece coupling demonstration

Leeb hardness tester selection

Your product information request

Please let us know your requirements and we will be in contact with you shortly!