Gloss Meters

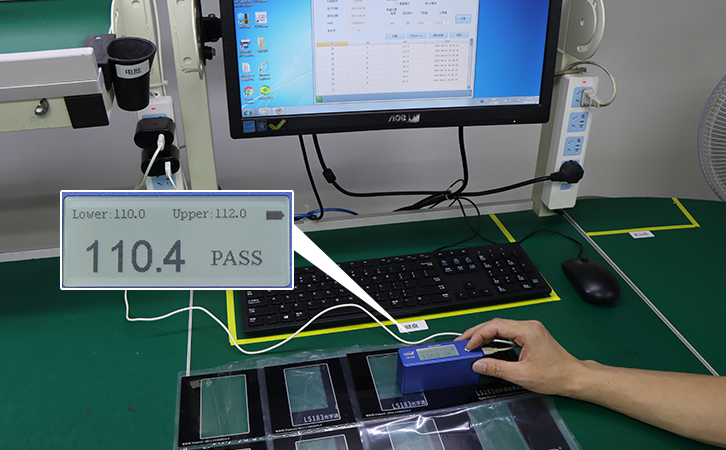

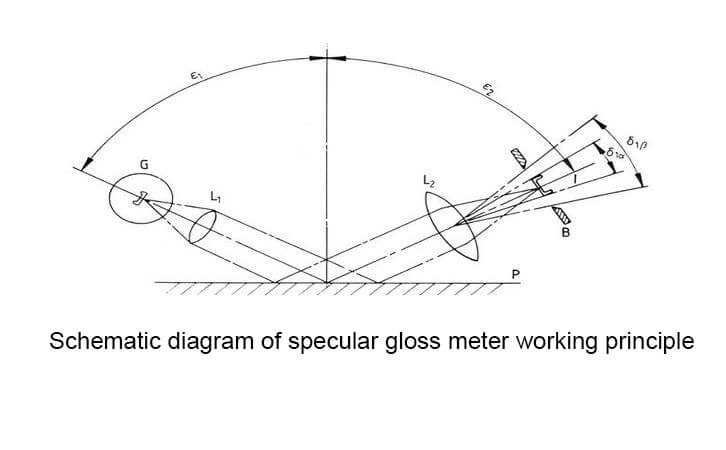

Linshang offers multiple types of gloss meters equipped with data statistics functions and professional software, providing efficient and precise gloss measurement solutions. As a professional gloss meter manufacturer, we are dedicated to delivering high-cost performance and high-accuracy instruments for evaluating gloss uniformity across various surfaces.

Our gloss meters are widely used in industries such as automotive, printing, paint, coating, ink, plastic, paper, tile, stone, metal, plating, and more. Whether you need to measure the gloss of car surfaces, marble, or painted coatings, Linshang gloss meters deliver consistent and reliable results with exceptional accuracy.

For more information about product prices, technical parameters, and model selection, please contact us directly.

LS190 Gloss Meter

60° universal angle (0-200GU range) | 1GU resolution

Budget-friendly entry-level solution

One-touch measurement - place & read instantly

Ideal for basic QC checks & field inspections

LS192 Professional Gloss Meter

60° universal angle (0-1000GU extended range) | 0.1GU resolution

Auto temperature compensation - ±0.2GU repeatability

Certified accuracy (Meets ISO 2813 & ASTM D523)

Aircraft-grade aluminum housing | Pocket-sized

LS193 Mini Measuring Aperture Gloss Meter

60° universal angle (0-1000GU range) | 0.1GU resolution

Ultra-small 3*6mm aperture (1.5*3mm spot)

Precision micro-surface measurement

Perfect for curved material/mini size material/jewelry

LS195 Cost-effective Gloss Meter

60° universal angle (0-200GU range) | 0.1GU resolution

Cost-effective gloss meter

Rapid QC mode - 50% faster batch testing

LS196 High-Precision Gloss Meter

60° universal angle (0-1000GU range) | 0.1GU resolution

ISO 2813 compliant measurement

Smart data trending with PC software

QC checks & field inspections

LS197 Tri-Angle Gloss Meter

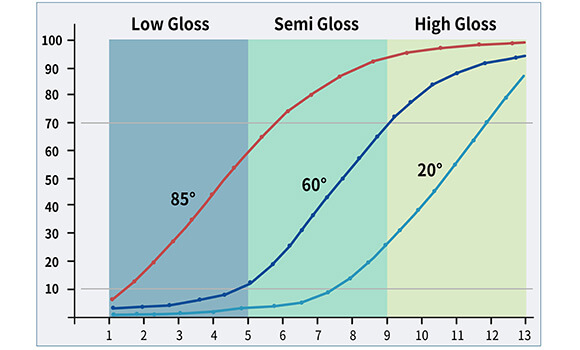

20°/60°/85° multi-angle (0-2000GU) | 0.1GU resolution

ASTM/ISO dual-certified results

Professional paint/plastic/metal gloss analysis

Application of gloss meter at different angles

Application of gloss meter at different angles Comparison between Linshang Gloss Meter and BYK

Comparison between Linshang Gloss Meter and BYK