How to Measure Gloss with A Gloss Meter?

I.What is gloss?

Gloss is a surface property of an object that involves specular reflection. It is a physical quantity that evaluates the ability of a material's surface to reflect light under a set of geometrically prescribed conditions. Specular reflection is the reflection that occurs when light is projected onto a smooth, uniform surface. Glossiness follows the law of reflection, which states that when light is reflected from a surface, the angle of incidence is equal to the angle of reflection. When light hits a smooth surface, such as a mirror, a car or water surface, specular reflections occur. This reflection makes the object look shiny. We usually use the GU to represent the surface gloss of the object, which is the abbreviation of the English word -gloss unit.

II.Why measure gloss with a gloss meter?

2.1 Gloss meter control gloss quality of products

The gloss meter can be used to control the gloss of the product. Gloss meters provide glossiness measurement tool manufacturers with a quick and easy way to evaluate the surface characteristics of their products. For manufacturers producing high-volume products, the gloss meter has brought them great convenience. Many factors affect the gloss of the surface, such as the substrate, the thickness and quality of the coating and polishing. When the gloss of the same batch of products is inconsistent, customers often suspect that there is a problem with the product quality. In severe cases, they will require the product to be reworked. Therefore, manufacturers strive to maintain uniform gloss for each product or batch.

Gloss can also be a measure of the quality of a product's surface. For example, the gloss decrease of coating's surface may indicate a curing problem. If there is a problem with curing, the quality of the product is difficult to guarantee. For these reasons, manufacturers in different industries such as automobiles, printing and furniture to food, pharmaceuticals and electronics all require product gloss monitoring.

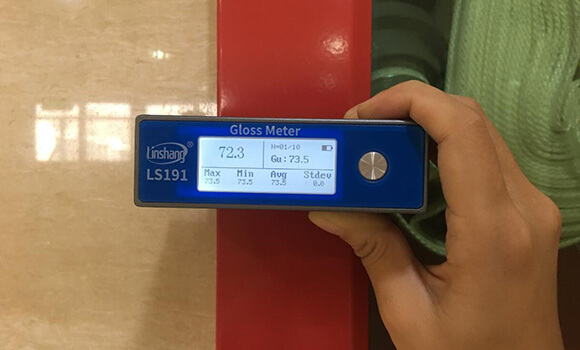

When you need to monitor the gloss of a large number of products, the data statistics function of the gloss meter is very important. The statistical function of the Linshang gloss meter has helped many gloss meter manufacturers. The Linshang gloss meter can automatically count the maximum, minimum, average and standard deviation values. The standard deviation can help analyze the gloss uniformity of the product. The smaller the standard deviation, the more uniform of the product gloss. After being connected to a computer, Linshang gloss meter can save up to 99 sets of data. After the measurement is completed, the measurement data can be exported and printed out.

2.2 Beautiful gloss attracts customers

Good product packaging is the first step to attracting customers. In fact, research has shown that product gloss has as much psychological impact on consumers as color has on consumers. In food packaging, packaging with good gloss can not only attract customers to buy, but also ensure the safety of customers. During the production process of food packaging, if the light source used for curing start to attenuate, the curing effect required by food packaging is not achieved. Then after the food is on the market, the paint on the packaging may peel off. By using a gloss meter to monitor the gloss of food packaging during the production process, food manufacturers can detect such problems early and avoid the above problems.

When buying a car, the appearance of the car is an important factor influencing the customer's purchase. People will evaluate the appearance of the car at the first time. Is the shape of the car what I like? High-end cars usually have good gloss and good gloss will create a high-end feel. At the same time, good gloss is an important factor that reflects the grade of the car. The gloss meter plays the same role in other industries such as furniture, paper, and paint.

III.How is gloss measured with gloss meter?

3.1 What is gloss meter?

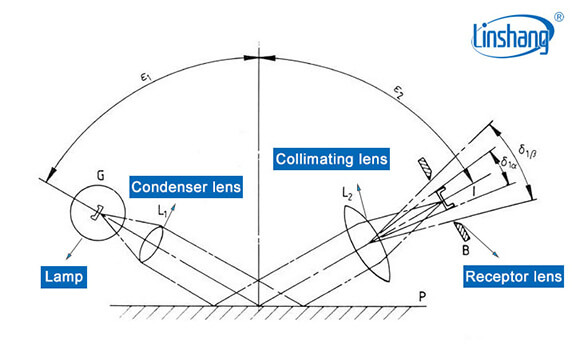

Gloss meter (also known as gloss tester) is an instrument used to measure the specular reflection (gloss) of the object surface. Gloss is determined by projecting a light beam onto a surface at a fixed angle and measuring the amount of reflected light at equal but opposite angles.

3.2 How does a gloss meter work?

The gloss meter uses the principle of light reflection to measure the gloss of the sample. That is: at the specified angle of incidence and the specified beam. The sample is irradiated under the conditions of 5% to obtain a beam of light in the direction of the specular reflection angle. Gloss meter consists of light source, lens, receiver and display interface,etc. Its measurement principle is divided into two types of parallel optical path (see the figure below) and convergent optical path.

3.3 60 degree gloss meter

(1)Why the 60 degree angle gloss meter is the most widely used?

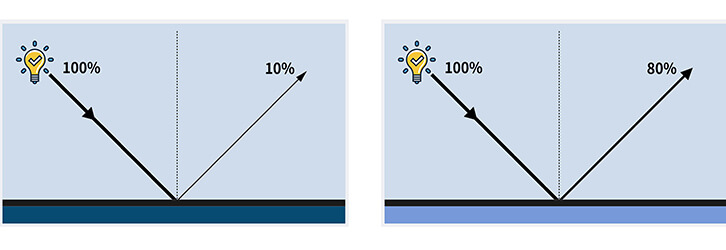

The specular reflection ability of a material depends on the refractive index and incident angle of the material surface that reflects the light. Metal materials with high gloss usually have a strong specular reflection ability. When light shines on a material with low gloss, part of the light will be absorbed or scattered by the object surface, so the specular reflection ability of a low gloss material is weak. As shown below:

Gloss is a relative measure of specular gloss. The reference standard is black glass with a refractive index nD = 1.567. Assuming that the object surface is ideally polished, the object surface will reflect the natural light beam specularly. Define the gloss value at this time as 100.0 gloss units, expressed as GU. The gloss measured by the gloss meter is the ratio of the specular direction reflected light flux on the object surface to the specular direction reflected light flux on the standard black glass under the conditions of the specified light source and receiving angle. (Cited from the document "Specular Gloss Meters and Gloss Plates JJG 696-2002")

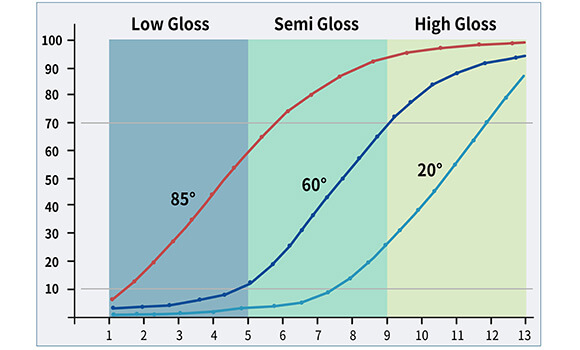

As shown in the figure above, the specular reflection ability of low-gloss materials is weak. If you use a 20-degree angle gloss meter to measure the object, the light flux received by the detector is very weak after reflecting on the material surface, compared with the light reflected by black glass. The data is small. Therefore, when measuring low-gloss materials with different gloss, the measured value changes are very small. And the resolution is not enough to distinguish the slight differences in the material gloss. But 20 degree angle gloss meter is suitable for measuring high gloss materials.

Similarly, if an 85-degree angle gloss meter is used to measure high-gloss materials, the resolution is not enough to distinguish the gloss difference of the materials. But it can be used to measure low gloss materials.

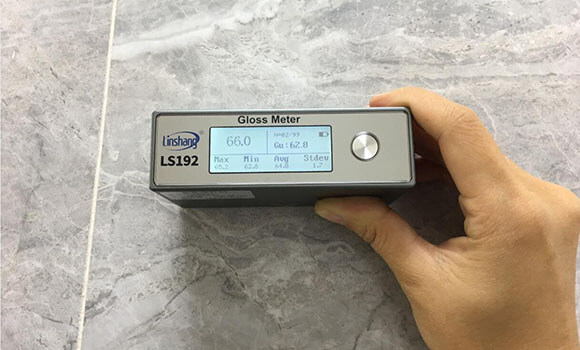

The 60-degree angle gloss meter has certain advantages when measuring a variety of different gloss materials. Generally, the measurement range of a 60-degree angle gloss meter is 200GU. If you need to measure high-gloss objects, the range is not enough. The resolution of the gloss meter is affected. As a professional glossmeter manufacturer, Linshang Technology has developed two 60-degree angle glossmeters with a range of 200GU and 1000GU, which solves the problem of resolution. Therefore, Lin Shang 60 degree angle gloss meter can also measure high gloss materials. As long as the gloss range is within 1000GU, we recommend using a forest gloss meter. The gloss of most materials is within 1000GU, so the forest 60 degree angle gloss meter can meet the needs of most customers.

(2)Pros of Linshang 60 degree gloss meter

● High measurement accuracy is extremely high

● Intelligent statistical data

● Ultra-wide range, LS192 gloss meter measurement range can reach 1000GU.

● High measurement accuracy

IV.How to choose gloss meter?

Gloss meter is an important glossiness measurement tool for detecting the object gloss. So how to choose a gloss meter that suits you? We can consider from the following aspects:

4.1 Gloss meter accuracy

The repeatability and reproducibility of the gloss meter are two important indicators for measuring the accuracy of the gloss meter.

Repeatability refers to using the same glossiness measurement equipment to measure the gloss of the same object surface. The data from multiple measurements remains consistent and within the error range. Reproducibility refers to measuring the gloss of the same object surface with the same batch of instruments. And the data from multiple measurements remains consistent within the error range. Only when these two data are good, can it be called a high-precision gloss meter.

4.2 Gloss Meter Price

While pursuing the performance of the glossiness measurement equipment, we must also consider the price of the gloss meter. BYK gloss meter with the same performance as Linshang gloss meter, the price reaches 10,000-30000 RMB. And Linshang Technology developed a large range of gloss meter LS192 only cost 2010RMB, the measurement range can reach 1000GU.

4.3 Features of Gloss Meter

When performing batch measurements, we often need to use data statistics functions and data storage functions. The Linshang gloss meter can automatically count the maximum, minimum, average and standard deviation values. The smaller the standard deviation value, the more uniform the gloss of the object surface. Linshang gloss meter can store 99 sets of data after connecting to a computer. Linshang gloss meter also has a temperature compensation function to ensure stable measurement data.

V.Gloss meter by industry

Gloss meter is widely used in various industries as a professional gloss measuring instrument for measuring gloss. As long as there is a gloss measurement industry, you can choose such a gloss meter. Below, we will list some common application industries of gloss meter:

5.1 Coating gloss meter

When painting the surface of a product, the painter generally needs to control the gloss of the product. If the products produced have different gloss of surface coating, it will affect customers' purchase. They often need to control the amount of paint sprayed on the product surface to ensure the service life of the coating and the anti-corrosion performance.

5.3 Gloss meter used in the automotive industry

The gloss of a car paint surface affects the price of the car and the purchase of the customer. Different parts of the car and car interiors have different requirements for gloss. The car body usually needs to maintain high gloss,while the gloss of the car interior will be matte.

5.4 Furniture gloss meter

When producing furniture, manufacturers usually need to spray paint and polish the furniture to achieve the desired gloss effect. Throughout the process, furniture manufacturers must control the gloss of their products to ensure batch consistency and check that the coating has been applied and dried properly.

5.5 Paper gloss meter

The printing industry has strict regulations on the gloss of paper. The use of different gloss papers will be different. High-gloss paper has strong specular reflection ability, which easily causes eye fatigue when reading. For example, materials such as coated paper, color printing, packaging, outdoor posters, we must use high-gloss printing paper, while traditional paper books should not have high gloss in order to improve the reading experience. Paper gloss meters can help manufacturers control the gloss of paper when producing it.

5.6 Paint gloss meter

At present, the paints on the market are mainly divided into various gloss types such as matte, high-gloss and semi-matte. The most popular gloss type is matte paint. Generally speaking, matte paint is paint with gloss below 20GU and semi-gloss paint between 40 and 60GU. (Specified test angle 60 °) The paint used in different places has different requirements for gloss, so the paint gloss needs to be measured to avoid rework.

5.7 Marble gloss meter

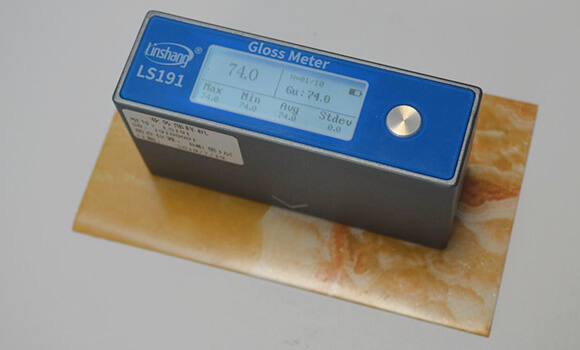

Gloss is an issue that everyone is more concerned about in stone care engineering. Many people even use it as the sole measure of the project quality. Natural stone is mainly divided into granite and marble. Generally, the gloss of natural marble is about 80GU and most of granite is about 90GU. In the current standard of natural marble slabs, the gloss value is classified. The lowest gloss value of superior products is divided into 3 categories according to the main chemical components, which are 90GU, 80GU and 60GU. The standard gloss of marble is really measured with a professional marble gloss meter.

5.8 Tile gloss meter

When some customers buy tiles, they judge the quality of the tiles based on their gloss. The higher the surface gloss of the tile, the better the sintered compactness of the tile. For good tiles, the glazed surface presents a clear and translucent feeling. Under the illumination of the light, the light is reflected out like a mirror. For poor tiles, the glazed surface is dull. Therefore, in the production of ceramic tiles, ceramic tile manufacturers usually use a tile gloss meter to measure it to ensure the quality of the product.

If you are not sure which glossmeter is suitable for your industry, you can call Linshang Technology's customer service staff. We will provide you with professional answers. At the same time, many users feedback that when using a gloss meter to detect the surface gloss of an object, it is also necessary to detect the color difference of the object surface. Some products also need to detect the coating layer thickness.