Application of UV Energy Meter in PCB Exposure Machine

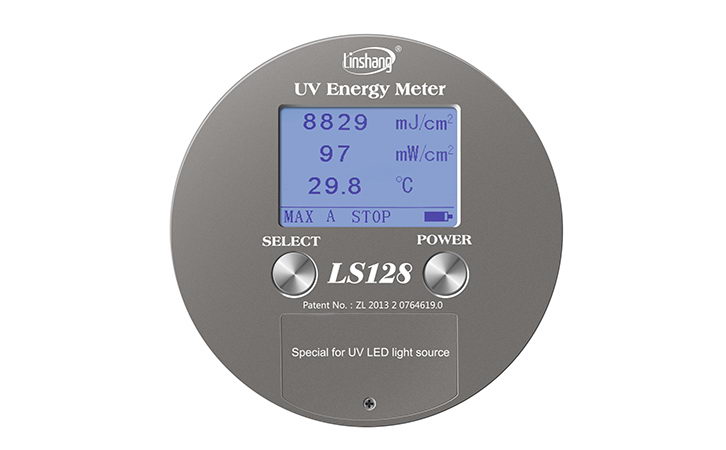

The Linshang LS128 UV energy meter is suitable for detecting the energy of the UV light source of the PCB exposure machine and the UV LED energy meter. It can measure the UV intensity and energy and can display UV intensity curve.

In the PCB production process, a necessary process is exposure. The exposure machine is needed, the traditional PCB exposure machine uses a high-pressure mercury lamp source for exposure. Due to the high calorific value and large volume of high-pressure mercury lamp and other unfavorable factors. With the emergence of high-power UV LED, replace the high-pressure mercury lamp sources with UV LED light source in PCB exposure machines is an inevitable trend.

UV LED light source is used in PCB exposure machine, two light source indicators that need attention:

1, optical parallelism

2. The uniformity of the entire lamp.|

Using the UV LED light source as the exposure machine light source, it is necessary to have several ultraviolet LED light sources to form an LED array, so that the luminous efficiency of each LED may affect the uniformity, and the ultraviolet light uniformity affects the exposure quality of the PCB. If the uniformity is poor, it will affect the unevenness of the exposure thus affect the quality of the PCB.

The LS128 UV LED energy meter measures UV intensity and energy and display the UV intensity curve. This can be due to:

1. The factory uniformity test of UV LED light source needs the UV intensity curve recording function. Directly move the LS128 from the left side to the right side of the light source and view the light uniformity of the cross section of the light source through the intensity curve.

2. The attenuation and uniformity of the light source during the production process.

UVLED exposure machine light source advantages:

1. More than 86% energy saving compared with traditional mercury lamps, no need to replace the lamp, no cooling water

2. Instant on or off, no standby losses.

3. Precise optical combination, so that the parallel half angle of the light source projection is less than 2°

4. With no infrared, avoid the expansion and contraction of the film, stable image transfer quality

5. LED point-by-point correction system to ensure the consistency of luminous intensity

6. With no mercury, no ozone, UV led technology purification production environment

7. LED service life exceeds 10,000 hours, energy attenuation is less than 1%, stable production and quality.

- UV Curing Machine and UV Radiometer

- Several UV Curing Lamps and Corresponding UV Energy Meters

- UV Curing Equipment of UV LED Irradiator and UV Energy Detector

- UV Energy Meter for Optical Communication Industry

- Application of UV Light Meter in Water Treatment

- UV Energy Meter Applied on UV Exposure Machine