UV Curing Equipment of UV LED Irradiator and UV Energy Detector

At present, UV curing equipment according to the different light source is mainly divided into three types: arc electrode type, microwave electrode type and UV LED type. Compared with the traditional UV light curing equipment, the new LED UV curing equipment has advantages, such as temperature control, service life, irradiation intensity, energy consumption, switch control, environmental protection performance and so on

1. Service life

Mercury lamp life generally only 800-3000 hours, while the UV LED service life can reach 20000-30000 hours. UV LED can be lit only in need of ultraviolet radiation, the start time is short, the switch frequency has little effect on life.

2. Energy consumption

The traditional mercury lamp with long start-up time, opening and closing effect of lamp life, lamp in multiple irradiation operation gap also need light, necessary power consumption is large. While the LED UV type light source only consumes electricity when irradiation, the energy utilization rate is higher.

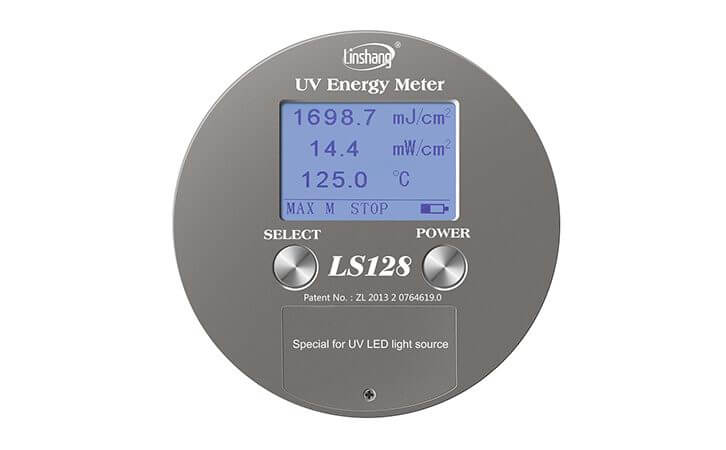

LS128 UV radiometer

3. Thermal radiation

The traditional UV light source not only includes ultraviolet ray, but also includes plenty of infrared ray. emits a large amount of heat produced by infrared ray. and the heat that can lead to a significant increase in the surface temperature of 60-90℃, which is easy to be used in the curing of adhesive or cured object. While UV LED is cold light source, emits single ultraviolet ray. The temperature rise of the product surface is less than 5℃. UV LED curing mode has great advantages in the optical lens and electronic products bonding, the thermal sensitivity and high precision of the plastic substrate and fiber optic cable.

4. Super intensity

UV LED because the light emitting area is small, via the special optical system design can make UV light to achieve high precision and high intensity irradiation, irradiation intensity can reach 2 times the mercury lamp, make UV curing adhesive faster, highly improving the curing efficiency.

5. Environmental protection

Traditional UV curing light source of the lamp contains mercury, waste lamps need to be specially processed and transport is very troublesome, once handled unproperly will have a serious environmental pollution. and LED UV is actually a semiconductor light emitting, no pollution to the environment.

From above-mentioned advantages, that’s why UV LED been more and more widely using in UV curing. But all UV Energy Detector are designed basic on mercy lamp. Comply with the development of UV LED extensive usage, in 2014, Shenzhen Linshang Technology Co. , Ltd. specially launched LS128 UV Energy Detector, while on market, as the first and only one special for UV LED curing. Its design refer to spectrum of UV LED. The measured value is more accuracy.