What is ultrasonic thickness gauge?

In order to measure the effects of corrosion on metal, pipes, or any structure where access is restricted to one side, ultrasonic thickness gauges (also known as ultrasonic thickness testers, ultrasonic wall thickness gauges, ultrasonic thickness meters, etc.) measure the wall thickness of materials such as steel, plastic, and more.

Measuring the thickness is crucial in many sectors in order to verify the material's state and ensure the structural or operational safety of the objects. When determining if a ship, tank, pipe, or steel structure needs to be repaired or replaced, ultrasonic thickness meter may be used to measure the thickness of a variety of accessories or metallic structures. The gauge may be used in a variety of industries including shipbuilding, aviation, aerospace, chemical, and petroleum.

The principle of ultrasonic thickness gauge

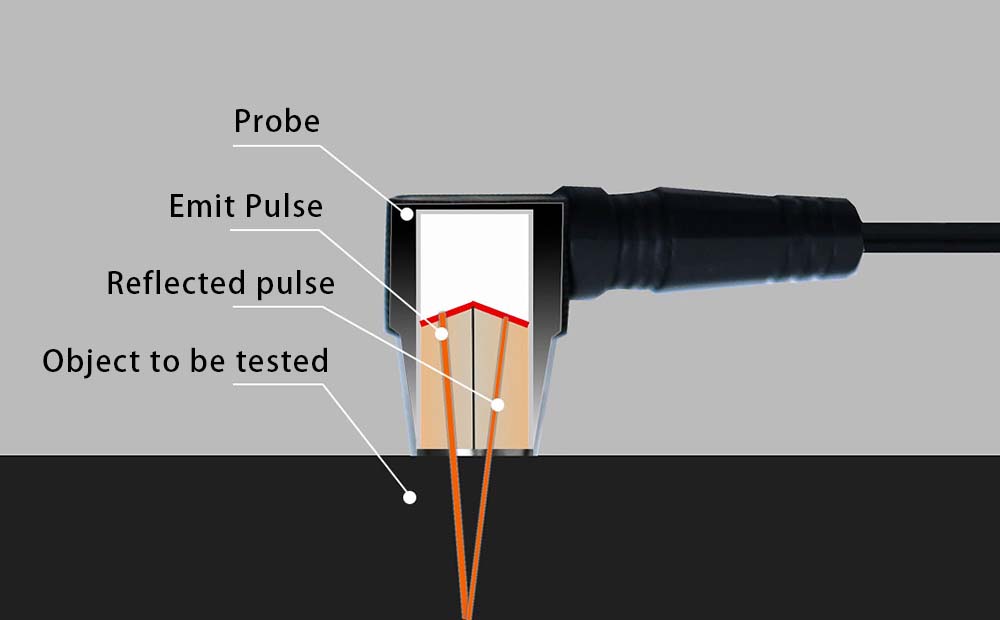

Ultrasonic pulses are sent into the material being tested using ultrasonic thickness probes. This pulse travels through the substance to the opposite side. The pulse is reflected back to the probe when it encounters a contact, such as another substance. Using an ultrasonic thickness gauge, the length of time it takes for the pulse to travel through the material is calculated.

Products

High resolution:0.001mm

High resolution:0.001mm

Resolution:0.01mm

How to use ultrasonic thickness gauge?

1.Probe connection method

Install the battery after obtaining the instrument, after which connect the host and probe. The probe has two aviation plugs that are placed separately above the host and may be utilized after being connected.

2.Calibration

The instrument will ask you to undertake benchmark adjustment, or calibration, after it has been switched on. It is advised to calibrate the instrument before use if it has been in operation for a while or has not been.

Apply couplant to the standard block at the bottom right of the instrument before pressing the probe firmly against it and maintaining your position. The calibration's progress will be shown on the screen after a beep sound. You can use it after being prompted that the calibration is finished and entering the measurement interface.

3.Selection of instrument measurement mode

The statistics mode is the default setting when the Linshang ultrasonic thickness gauge is turned on. The other measurement mode is the quality control mode.

In the statistics mode, you can examine the measurement's current value as well as the test's maximum, lowest, and average values. In usually, the thickness of the workpiece to be measured is determined by taking the least value, therefore this mode is appropriate in this circumstance.

Before using the QC mode, the system settings of the main menu interface must be specified. You must specify the appropriate upper and lower limit settings if you select QC mode. To change the precise upper and lower limit values, using the up and down or left and right keys.

When in QC mode, the device will automatically determine whether or not the thickness of the material being measured qualifies based on the upper and lower limit values. Scenes that need for quick detection are a great fit for it. For instance, in the typical grid measuring method, points are measured for thickness after a grid has been drawn in the prescribed region. Data is then recorded after the test, and the unqualified place is marked to make further monitoring easier.

Method of use

1.Identify the material and its thickness.

If you wish to measure the thickness of a material, you need first determine what kind of material it is.

To prepare for the test, choose the sound velocity setting on the ultrasonic thickness gauge's main menu interface, choose a known material to set the sound velocity for, enter the material selection interface, and then, after choosing the appropriate material, go back to the measurement interface. Apply some couplant to the material's surface before pressing the instrument's probe firmly against the material's central surface to measure the thickness of the material.

2.Set the sound velocity to measure the material's thickness.

If the material's sound velocity is known, measuring the thickness may be done fairly easily by manually adjusting the sound velocity.

First, select "Manually Set Sound Velocity" from the main menu. Then, using the up and down and left and right keys, change the material's real sound velocity. Finally, save the setting after adjustment. The device can gauge the material's thickness during the test based on the specified sound velocity.

3.Utilize a material with a known thickness to measure the speed of sound through it, and then use that measurement to determine the thickness of a nearby material.

The reverse sound velocity measuring method can be used if the thickness of a material is known and you wish to measure the thickness and sound velocity of another material made of the same material.

Introducing LS212 ultrasonic thickness gauge

This video describes how the LS212 Ultrasonic Thickness Gauge measures thickness in a variety of applications.

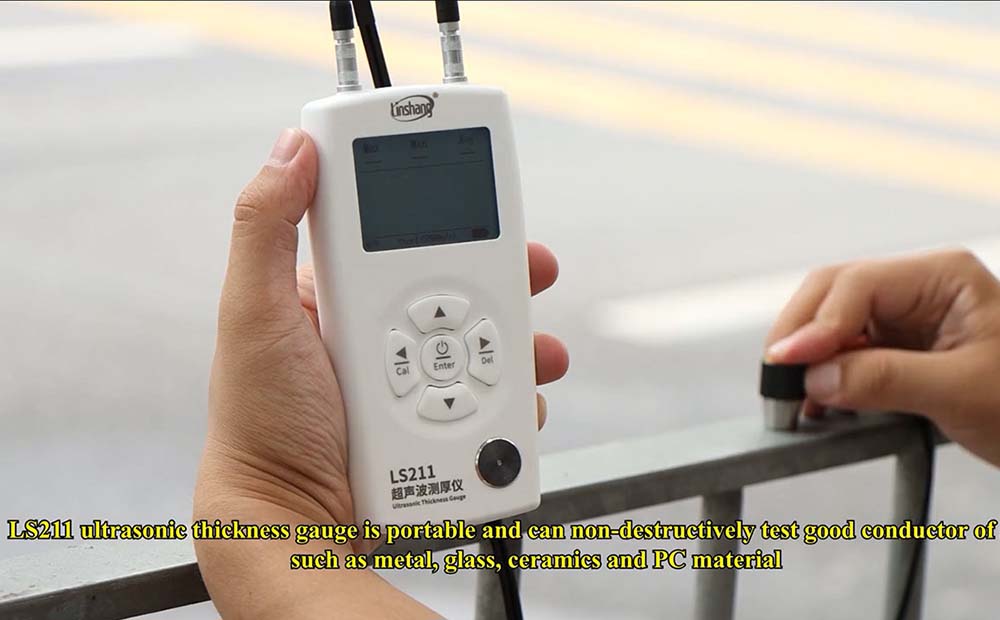

Introducing LS211 ultrasonic thickness gauge

LS211 ultrasonic thickness gauge's characteristics and functioning are described in depth in this video.

How accurate are Ultrasonic Thickness Gauges?

The time it takes for the pulse to travel through the substance being tested and the material's sound velocity indicate the thickness of the material. The professional timing chip that is already present in the ultrasonic thickness gauge has high test accuracy and stability. And the resolution may be as precise as 0.001mm. The equipment has a high degree of testing accuracy, up to 0.05mm.

Features of Ultrasonic Thickness Gauges

1.Dual crystal probe

A high-sensitivity ultrasonic dual-crystal probe that can both transmit and receive ultrasound is employed by the Linshang Ultrasonic Thickness Gauges. Between the two wafers of the probe, there is a layer of sound insulation with strong sound absorption and good insulation.

This layer can be used to prevent mutual interference and blockage of the emitted and reflected sound beams, as well as to narrow the pulse, enhance resolution. And eliminate reflected clutter that would otherwise enter the receiving chip between the transmitting chip and the delay block. This layer also effectively reduces clutter.

2.Automatic gain

The material's composition and thickness will have an impact on the probe's ability to detect signals. To provide the best measurement results, the Linshang ultrasonic thickness detector can automatically choose the proper gain, or signal amplification factor, based on the thickness of the material.

3.Multiple sound velocity settings

The instrument includes the sound velocities of several common materials built in, making it simple to measure switching materials quickly.

The description of the ultrasonic thickness gauge is complete above.

- FAQ of Linshang LS300 and LS301 Solar Film Temperature Meter

- Application of gloss meter in automotive industry

- Can Window Film Protect Against Ultraviolet Rays?

- Measurement and Industry Background of Powder Coatings | Powder Coating Thickness Gauge

- When do We Need to Make Zero Adjustment for the Automotive Paint Meters?

- LS129 UV Illuminance Meter for Communication