UV Integrator Dedicated to High-pressure Mercury Lamp

From a professional level, an UV integrator dedicated to high-pressure mercury lamp curing light sources is the basic guarantee for accurate and efficient curing in the industry. Ultraviolet curing is an advanced technology that uses the strong energy of ultraviolet to dry and cure products. Compared with traditional drying technology, both the time cost and economic cost have been greatly reduced.

In the printing and dyeing industry and the photovoltaic industry, UV curing technology is a widely used fast drying technology. The corresponding UV curing equipment is an essential precision instrument. One of the key functions is the curing light source. We generally use high-pressure mercury lamps as the standard light source. The UV integrator is an important measuring device for detecting the energy of high-pressure mercury lamps.

The UV integrator dedicated to high-pressure mercury lamp curing light source is very rich in statistical functions. It can also generate continuous data curves when connected with special computer software. Generally in the quality inspection department and manufacturers are the best artifacts for testing product quality and screening products with high standards. Compared with other energy lamp sources, the spectrum of the high-pressure mercury lamp is wider. The ultraviolet energy bands emitted are not similar. And the use of UV integrator measurement can screen different ultraviolet radiation bands and purify the rays as much as possible.

In addition to the huge energy, we often analyze it from the aspect of heat. After practical use, it will be easy to find that the high-pressure mercury lamp has high heat and brightness that are difficult to compare with other light sources. This is due to its wide spectrum. In UV curing technology, the energy actually required only takes up a small proportion of the total energy. The role of the UV integrator is to select the most effective ultraviolet waveband most accurately.

In addition to the above basic functions, we will also find that improper selection of the light source energy of the high-pressure mercury lamp will cause deformation of the radiated product and cause more serious physical harm to people. During normal printing, the actual energy value of the high-pressure mercury lamp will gradually decrease with the extension of the use time. In other words, the working life of the high-pressure mercury lamp is very short, which is not conducive to the smooth progress of printing and curing. The huge function of the UV integrator appeared at this moment. People in the industry can choose a regular maintenance and repair date to replace the unqualified high-pressure mercury lamp tube.

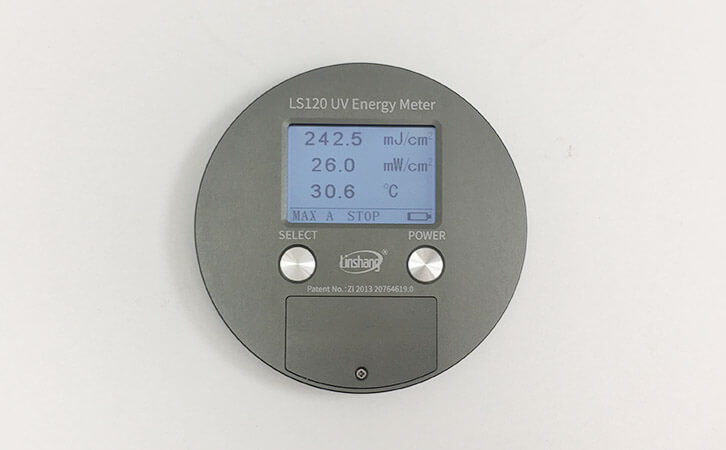

Then the UV integrator should also choose a dedicated instrument as much as possible. The range and accuracy of this high-pressure mercury lamp professional UV integrator are closer to the industry requirements. The operation is more convenient and simple. The UV integrator developed and manufactured by the Linshang Technology can view the last test data after the machine is turned on. After a certain operation, it is also convenient to review the basic statistical indexes such as the maximum and minimum values.

Because different industries pay attention to high efficiency and low cost, the intelligent UV integrator is more convenient for technicians to check and compare. Linshang UV integrator can also be quickly connected to computer software for easy reporting, classification and printing.