UV Energy Meter | Color Curing Technology of Pigments

The color curing technology of pigments can help people solve the problem of color printing and dyeing, which cannot do without the huge role of ultraviolet rays. In general, the UV energy meter can detect the intensity and energy of ultraviolet rays.

The world we live in is colorful. Complex colors are inseparable from the blending of pigments and printing and dyeing. In most cases, the ordinary three primary colors can no longer meet the basic public needs. With the development of technology, UV curing has gradually replaced the traditional technology. UV curing is also known as ultraviolet curing. Using an UV energy meter can effectively detect the intensity and energy of ultraviolet rays.

In theory, the absorption capacity of light by different colors is very different. Often dull colors will have a strong ability to absorb light, while lighter colors are more likely to reflect light. It is precisely for the application of this physical property and the development of the UV energy meter that scientific and technological personnel have developed UV curing technology.

UV curing technology uses the different wavelength bands possessed by ultraviolet rays, which can be absorbed by different colors. In addition, our well-known UV curing technology has not only appeared in the pigment curing industry, but also has been applied in ink, paint, furniture manufacturing and other industries.

UV curing agent is a substance that can change small molecules into large molecules, which can significantly improve the quality of printed products, make the finished products more delicate and beautiful. Generally speaking, UV curing technology can make the curing of pigment colors more clean and neat, which greatly avoids the problems of ghosting and blurring. The UV curing technology in the professional field requires the use of specific wavelengths of ultraviolet light. Only by using an UV energy meter can this value be truly accurate.

The role of UV energy meter is specifically to help people quantify the ultraviolet energy and control the energy of the ultraviolet lamp in the required range. It can also stabilize the light intensity, so that the ultraviolet radiation has a certain stability, thereby ensuring the smoothness of printed products. The unit of UV energy meter for measuring light source equipment is nanometer level, which is very accurate.

In many printing and dyeing industries, we use different materials in the actual operation of pigment colors. Take titanium dioxide as an example. The ultraviolet band it absorbs is about 380nm (basically the band that can reflect all energy), which can be quickly and efficiently penetrate the layer to reach the bottom. Some UV lamps do not reach the standard due to light intensity. The thickness of the ink is too thick to reach the bottom smoothly. The finished product will be ghosted or lack basic definition. This kind of UV lamp requires technicians to use UV energy meter to detect and eliminate it in time.

Different types of UV energy meters play a very different role. Some are dedicated to the detection of LED lamps and some are dedicated to the detection of high-pressure mercury lamps. As a low-cost and long-life light source device, LED lamp has become the light source used by most production industries.

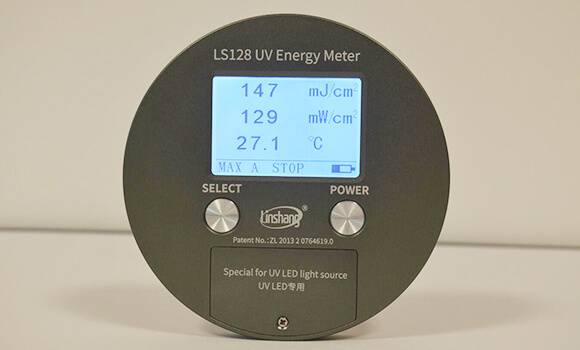

The LS128 UV energy meter developed by Linshang Technology can detect the ultraviolet energy of LED lights. In addition to this, this UV energy meter is very small and delicate, with high sensitivity during measurement, which is very suitable for industrial self-test.

- UV Power Puck | What are the Advantages of UV Printing Technology?

- UVC Light Meter | Demystifying the Efficacy of the Pass Box

- What is the Relationship between Textile Gloss and Fiber Morphology?

- Application of High-precision Coating Thickness Gauge in Thermal Spraying Process

- Effect of Gloss and Gloss Meter

- How to Choose a Paint Thickness Tester Meter Gauge