Specular Gloss Meter Used in Texture Surface of Mold

1. What's wrong with shiny mold surface?

The mold is a tool used to replicate the molded product. That is to say, the plastic solution flows in the cavity and replicates each cavity surface. The product with the cavity surface that is light and the cavity surface is textured. The product should also be textured, which is not difficult to understand. However, when a plastic product is cooled from a solution to a solid state, it will shrink continuously with the change of temperature. At the same time, the temperature will also affect the product's replication effect. The mold temperature and material temperature are low and easy to get black. At the same time, the injection pressure and holding pressure are small, which will also cause the product to be black and affect the product gloss.

(1) The area of the product near the gate is bright and it is dark away from the gate.

(2) Areas with uneven meat thickness and large changes in flow velocity.

(3) Corners of two sides of the product structure. The corner of the product is also a high incidence area of yin and yang, which is mainly due to the resistance of the material flow at the corner. The rapid change in flow speed and pressure is also one of the reasons.

(4) The tendon position on the back of the product is likely to cause local yin and yang.

(5) The product is at the joint where the two strands flow, that is, the area near the weld line is also prone to yin and yang.

(6) The uneven arrangement of the waterway on the appearance surface.

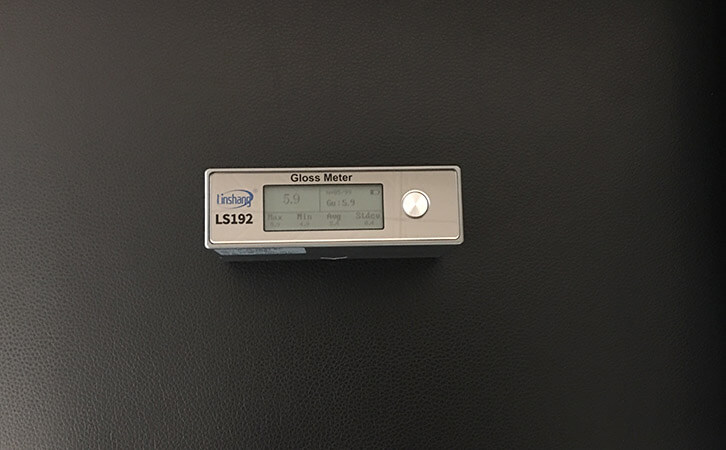

2. Specular gloss meter detects the mold surface

If the gloss of the products is not consistent, the appearance effect will be greatly reduced, which will cause the appearance treatment to be re-sprayed and increase the cost. What is more critical is that some products require flame retardant and environmental protection and the appearance becomes a problem. You can use a specular gloss meter to measure. The larger the incident angle of the specular gloss meter, the greater the specular reflectance, the higher the gloss. The smaller the angle of incidence, the lower the gloss. The 60-degree angle generally used on the market is like LS192, a universal 60-degree specular gloss meter from Linshang Technology, with a measurement range of 1000GU. High gloss and low gloss materials can be tested because the gloss is a relative value. When there is no uniform standard in the applied industry, it can be tested with the LS192 specular gloss meter. If the industry has a uniform standard, it is best to use the same angle of testing. Therefore, when selecting the measurement angle, you should choose differently according to different situations.