Application of Gloss Tester in Metal and Leather Industry

1. Application of gloss tester in metal industry

How to protect the color and luster of metal relics? Metal cultural relics account for a large part of the cultural relics unearthed in China. After being unearthed, metal cultural relics are particularly vulnerable to corrosion. In order to better protect these unearthed cultural relics, archaeologists analyze the impact on cultural relics from a physical, chemical and mechanical perspective. After researching, some protection schemes will be formulated based on the results of these studies. In the process of research, firstly we can use a gloss tester to determine the color information of metal cultural relics and try not to destroy the original color during the protection process. Mechanical, physical and chemical methods are used to remove rust and seal, but these short periods of time will definitely not show any effect. It has time to prove that, especially by chemical protection, it is easy to affect the changes in color. These small changes in the short term. It is also difficult to find the subtle change with the naked eye and photographic technology, but using a gloss tester can easily analyze the subtle changes in these colors over time.

One of the methods often used in archeology to remove embroidery is to immerse the etched bronzes in the sodium sesquicarbonate solution and soak them. The chloride on the surface of the bronzes will generate a stable copper ion through chemical reaction during the process. Carbonate, the chloride ions in the bronze are replaced by copper ions into the immersion solution. The immersion solution should be replaced at regular intervals until the chloride ion content in the immersion solution is almost zero. The treated bronze ware is repeatedly washed with distilled water until the surface is free of lye and then it is dried for sealing. This method is very simple and convenient to operate. But because of the long chemical reaction time, not only the surface of the bronze may be eroded, but also the interior of the ware may be eroded, which cannot be completely removed.

The change of color is the most difficult thing for the staff in the protection of cultural relics. The use of physical and chemical machinery is likely to cause the surface color to change most of the time. At this time, the gloss tester was used for identification. The results were improved and scientifically evaluated for protecting the surface of rusted bronze cultural relics.

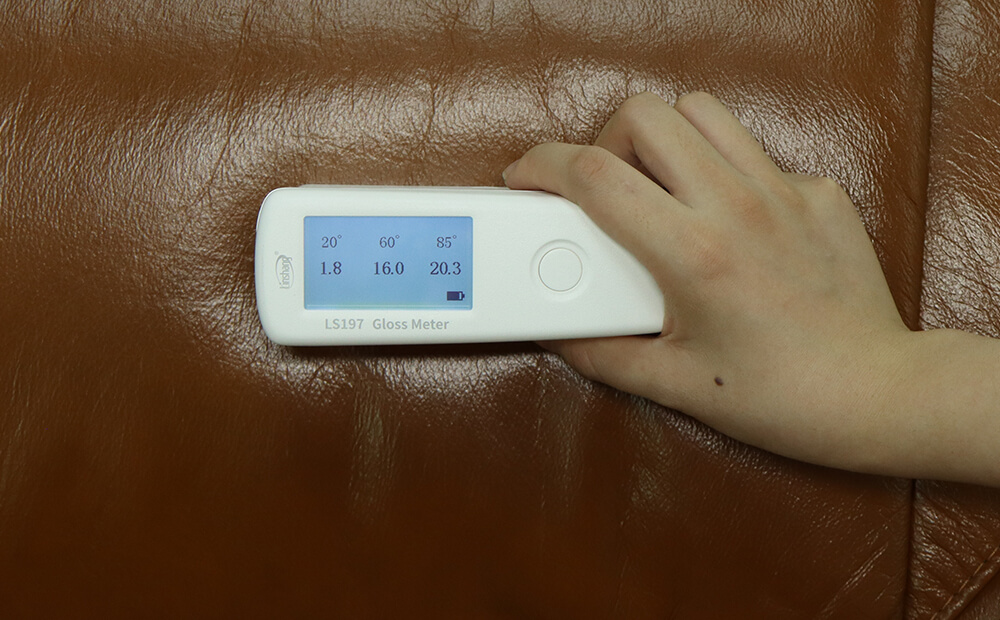

2. Gloss tester application in the leather industry

The surface color of the leather industry was measured by a gloss tester. The color difference of leather is largely affected by the color. Controlling the color of the leather can control the inconsistency of the color. Leather is a denatured and non-perishable animal skin obtained through physical and chemical processing such as depilation and tanning. Leather is a product of natural protein synthesis through three-dimensional space. The surface of leather has a special grain layer, which has natural grain pattern and gloss.

During the course of human evolution, we discovered that some plant juices or mineral oils have certain tanning properties on leather. The uncut leather will be more breathable and antiseptic through the soaking of these plant juices. So that the leather is softer, more tear-resistant and more resistant to twists and turns. The tanning agent is the sap of this plant. The tanning industry developed into a stable tanning agent in the middle of the last century and is roughly divided into the following three categories:

Vegetable tanning agent: mainly tannin, used for industrial leather or base leather.

Mineral tanning agents: mainly chrome and aluminum salts, used in various civil leathers. Such as clothing.

Organic tanning agents: mainly formaldehyde, glutaraldehyde, etc., used in furs and all kinds of fine leather.

The above is the basic application of the gloss tester in the metal and leather industry. In the process of use, you can choose the appropriate gloss tester.