Digital Gloss Meter | Influencing Factors of Computer Gloss

1. The importance of computer gloss

Computer case is usually made of plastic, metal and other materials. Due to the quality of the material and the difference in processing methods, the gloss of the computer will change. For the same type of computer products, if there is a large deviation in appearance gloss, it may affect the sales of computers. For example, a computer case with too low gloss will give people a dim and old feeling, which will affect consumers' evaluation of computer quality.

2. Factors Influencing Computer Gloss

Taking a computer with a plastic case as an example, the main factors affecting the gloss of plastic are:

(1) The influence of raw materials on the surface gloss of products

The characteristics of the resin itself have a great influence on the gloss of the product surface, which is an effective method for controlling gloss.

(2) The influence of processing technology on the gloss of plastic surface

For molded products, a surface-polished mold can be used to improve gloss of the mold to adjust gloss.

(3) The effect of filler on the gloss of plastic surface

Inorganic filler filled plastic products can impart high rigidity, heat resistance and dimensional stability, reduce production costs. Most inorganic fillers will seriously affect the high gloss of the clinker surface.

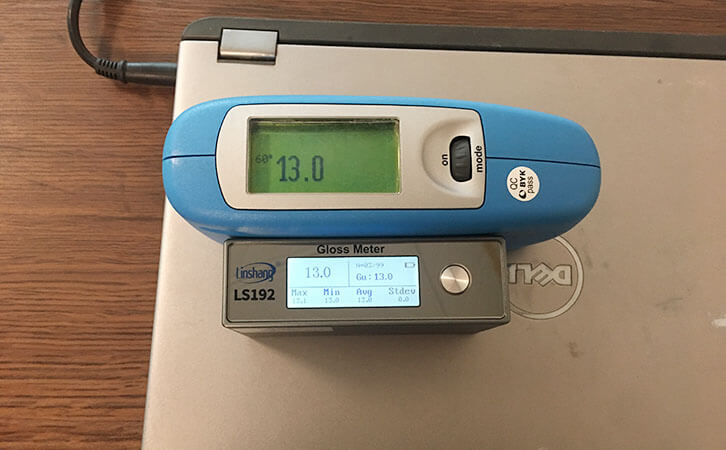

3. Digital gloss meter to determine the gloss of the computer

In order to control the quality of the production computer, a strict gloss test is required on the appearance materials of the assembled computer. Gloss is a measure of optical smoothness. Gloss directly affects the appearance quality and performance of the computer. It can also be used to check the uniformity of the product surface. Gloss is generally measured with a digital gloss meter. It is highly recommended to use Linshang LS192 digital gloss meter. The specific reasons are as follows:

(1) The ordinary design contains superb technical elements

Whether the digital gloss meter can measure accurately, the first thing to do is to make the standard value of the standard board accurate. Once the standard board is contaminated, the measured data will not be accurate. The clever design of the host and base of the LS192 digital gloss meter well protects the standard board from contamination. The instrument does not have to be calibrated every time it is turned on. In addition, the instrument has standard board fouling self-diagnosis function. When the standard value of the standard board is not within the qualified range, the instrument will automatically prompt you to clean the standard board. Currently only the LS192 digital gloss meter and digital gloss meter BYK have this function.

(2) Temperature compensation function

Digital gloss meter is a very sensitive instrument. Under different temperature environments, the luminous efficiency of the light source is different. The higher the ambient temperature, the lower the luminous efficiency; the lower the ambient temperature, the higher the luminous efficiency. The Linshang LS192 digital gloss meter has a real-time temperature compensation function, which guarantees the stability of the instrument regardless of the temperature environment, making the measurement results stable and reliable. The temperature compensation function is realized through the instrument's real-time detection of the current ambient temperature. According to the detected ambient temperature, the drive current of the light source is adjusted in real time to ensure that under different ambient temperature conditions. Although the luminous efficiency of the light source is changing, the intensity is the same, which ensures the measurement process. If the ambient temperature changes, the measurement data is still accurate.

(3) Automatic measurement and automatic statistical functions

LS192 digital gloss meter has automatic measurement function. When you need to test the uniformity of a digital gloss meter for a piece of material, you only need to place the instrument on the measured position of the material. There is no need to press the button during the measurement; The maximum and minimum values can be automatically calculated and displayed on the display interface.