Gloss Metre | Difference and Connection of Surface Gloss and Smoothness

When people observe the surface features of objects, they use gloss or smoothness to describe them. Among them, gloss is a feeling when the eye is watching and smoothness means a rough surface feeling when touching. To be more professional, gloss is the intensity of the diffuse reflection of the objetc surface against light, while smoothness is the degree of unevenness on the object surface.

1. How to understand the concept of gloss and smoothness?

Object surface gloss and smoothness are different concepts. Standard gloss indicates the surface's specular reflection of light. To the naked eye, the surface specular reflection is strong, which is closer to the mirror effect and the gloss is high. Conversely, the surface specular reflection is weak and the gloss is smooth. Therefore, gloss is also called specular gloss, which is affected by the physical properties of the object surface and the chemical properties of the material. If you want to measure the gloss, you need to use a special gloss metre.

The opposite of smoothness is roughness. One can use the surface roughness to indicate the smoothness of the product. The roughness here is generally formed by the processing method used and other factors, such as the friction between the tool and the part surface during the processing, the plastic deformation of the surface layer metal during chip separation and the high-frequency vibration in the process system. Due to different processing methods and workpiece materials, the depth, density, shape and texture of the marks left on the processed surface are different. Therefore, the surface roughness is an object characteristic of the product surface. The roughness of the same material has a great influence on its surface gloss.

2. Difference and connection between gloss and smoothness

From the above concepts, we can know that the gloss and smoothness of the object surface are two different concepts. But for the same object, the two have a great relationship. For example, the rougher the surface of the same type of plate, the stronger the diffuse reflection produced. The weaker the specular reflection and the lower the surface glossiness. On the contrary, the smoother the surface and the stronger the specular reflection light capacity, the higher the surface gloss.

But for products of different materials, there is no necessary connection between surface gloss and smoothness. For example, the smooth paper surface has a low gloss. Even a stainless steel surface that is not smooth enough has a higher gloss than the paper surface.

Therefore, in the field of industrial processing, gloss and smoothness are two different detection indicators, which can be measured by different detection instruments.

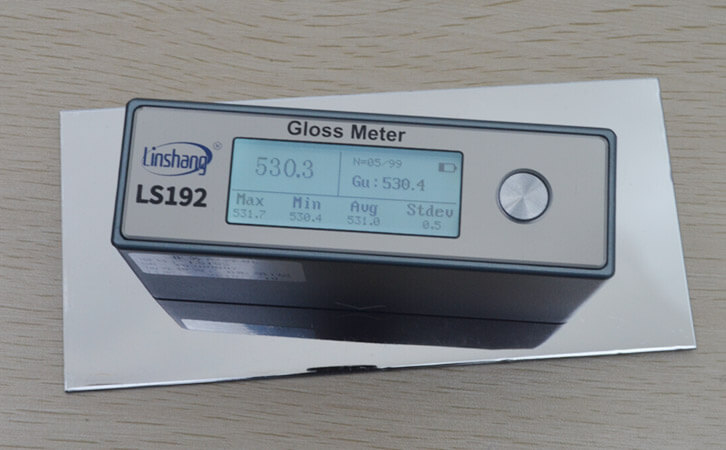

3. Gloss metre-gloss testing equipment

Gloss metre manufacturer Linshang Technology provides 60 ° gloss metre for surface gloss testing of stone, paint, metal, plastic, fabric, tile, ceramic and other materials. There are two types of models, LS191 and LS192, which are glossmeters produced in accordance with the national inspection regulations JJG 696-2002 "Mirror Gloss metre and Gloss Board". All indicators meet the requirements of the first-class working machine in the Chinese metrological inspection regulations.