Ultraviolet Energy Meter-Lithography Curing Lamp Inspection

Ultraviolet energy meter is also called UV energy meter, UV power puck, UV integrator, UV energy tester. It is an instrument for detecting ultraviolet energy. Ultraviolet energy meter is a kind of high-quality ultraviolet energy counting instrument, used to measure UV energy in different wavelength bands.

1. Application of ultraviolet energy meter in photolithography and curing industry

UV-curable photoresist is also called photoresist. It is a light-sensitive mixture composed of three main components: photosensitive resin, sensitizer and solvent. After the photosensitive resin is irradiated with light, a photo-curing reaction can occur quickly in the exposed area, which makes the physical properties of this material, especially the solubility and affinity. After treatment with an appropriate solvent, the soluble portion is removed to obtain the desired image. UV-curable photoresist is a key material for manufacturing printed circuit board (PCB) circuit patterns. It is mainly divided into wet film photoresist (also called "liquid photoresist") and dry film photoresist.

2. The process of photolithography curing

(1) Pre-treatment of the substrate: In order to ensure that the photoresist adheres well to the wafer surface and forms a smooth and well-bonded film, the surface preparation must be performed to keep the surface dry and clean.

(2) Photoresist coating: The goal of coating is to create a thin, uniform photoresist film on the wafer surface.

(3) Pre-baking (soft baking): The purpose of pre-baking is to remove the solvent in the adhesive layer, improve the adhesion between the photoresist and the substrate as well as the mechanical abrasion resistance of the film.

(4) Alignment and exposure: The decisive factors to ensure the normal operation of the device and circuit are the accurate alignment of the pattern and the formation of the precise pattern size on the photoresist. Therefore, after applying the photoresist, the first step is to accurately position or align the desired pattern on the wafer surface. The second step is to transfer the pattern to the photoresist coating by exposure.

(5) Development: Development refers to copying the mask pattern onto the photoresist.

(6) Post-baking (hard film): After the development, the adhesive film has softened and expanded. The adhesion between the adhesive film and the silicon wafer surface has decreased. In order to ensure that the next etching process can be performed smoothly. The photoresist and the wafer surface are better adhered, the solvent must continue to be evaporated to cure the photoresist.

(7) Etching: Etching is the process of removing the outermost layer of the wafer through the exposed area of the photoresist. The main goal is to accurately transfer the pattern on the lithographic mask to the wafer surface.

(8) Removal of photoresist: After etching, the pattern becomes a permanent part of the wafer outermost layer. The photoresist layer as an etch barrier is no longer needed and must be removed from the surface.

3. Selection and application of ultraviolet energy meter

Ultraviolet energy meters can be used in a wide range, such as UV dryers (UV curing), UV exposure equipment, UV inks, UV coatings, UV glue, UV printing, PCB circuit board exposure, UV floor paint, UV glazing, etc. Ultraviolet energy meter, as a high-quality, high-precision measuring instrument, is used to measure the irradiation energy value of different light sources under certain conditions. It is an extremely important curing quality detection instrument in the UV production process, which can well control and achieve consistent product quality. The ultraviolet energy meter parameters induced ultraviolet wavelength are in accordance with national standards.

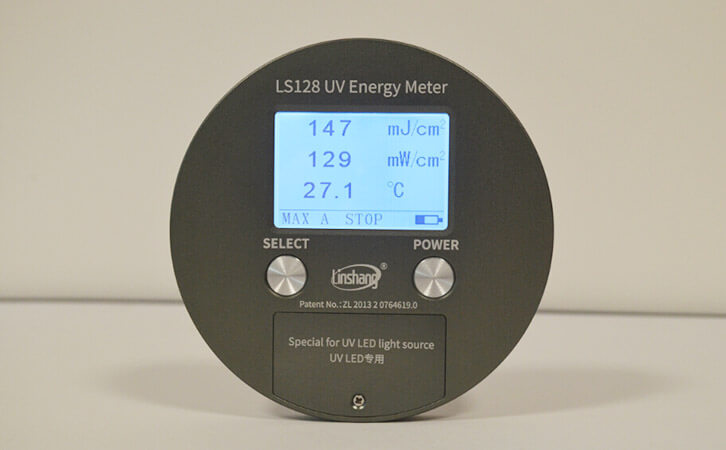

The ultraviolet energy meter is recommended to choose Linshang Technology. Linshang Technology has developed ultraviolet energy meters for LED lamps and mercury lamps. It is recommended to use the LS128 ultraviolet energy meter for UV curing industry.