Measuring Principle of Specular Gloss and Selection of Gloss Meter

1. Measuring principle and type of specular gloss

The measurement principle of specular gloss is the ratio of the reflected light flux of the sample in the specular reflection direction to the specular reflection light flux of the glass standard under the conditions of the specified light source and receiver opening angle. Polished black glass with a refractive index of 1.567 sets a specular gloss value of 100 (gloss unit) at a geometric angle of 60 degrees.

A light source emits a beam of light through the lens L1 to the measured surface P. The measured surface reflects the light to the lens L2. The lens L2 condenses the light beam to the photovoltaic cell located at the light column B. After the photovoltaic cell performs photoelectric conversion, the electrical signal is sent to perform processing. The instrument displays the measurement result. It should be noted that throughout the gloss measurement process, the light of the default light source is very stable and will not change.

The surface gloss of most objects is neither completely specular nor completely matte and usually falls between the two. Studying the specular gloss of the object surface can more intuitively describe the gloss characteristics of the object. It can be used in some industries to check the appearance of the product.

2. Precautions for using the gloss meter

Gloss meters are generally built-in batteries. Please use original batteries. Do not replace or use other batteries to prevent damage to the instrument or other failures.

Do not disassemble, squeeze, blow, or heat the battery privately, or place the battery in a fire or high temperature environment, otherwise the battery may explode and cause a fire.

When the instrument is fully charged, when not in use, the external power supply should be cut off to prevent electric shock and damage to the instrument. If the instrument is not used for a long time, the instrument should be recharged once every two weeks. Otherwise, the internal battery will be easily damaged and the instrument cannot be used again.

The first few times you use the instrument for charging, it is best to fully charge the battery and then use it up. When external power supply is required, please use the standard power adapter of the instrument. Do not use other power adapters that do not meet the technical specifications. Otherwise, it may shorten the battery life. If the instrument is not used for a long time, the external power supply should be cut off to prevent burning the instrument and causing fire.

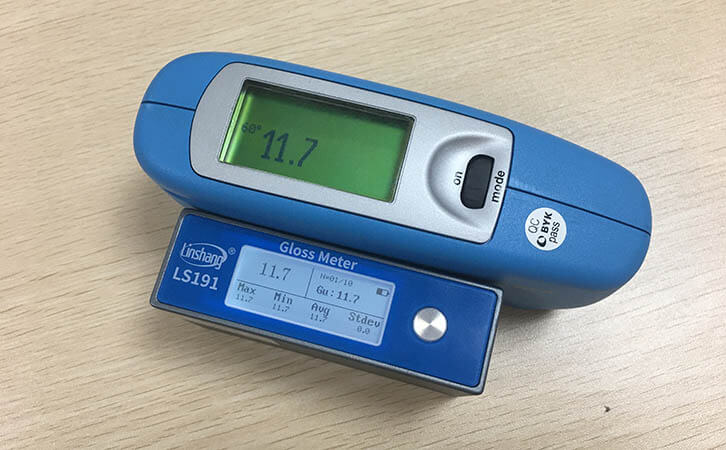

3. Linshang gloss meter LS191

Linshang Technology is a Chinese glossmeter manufacturer integrating R & D and production. Although there are many manufacturers of different brands in the industry. However, as a professional manufacturer, Linshang gloss tester not only measures the accurate data, but also has a very good price / performance ratio and function.

Linshang gloss tester LS191 is produced according to the JJG 696 standard in the national inspection regulations. It can ensure that it passes the national measurement and meets the requirements of the first-class working machine. The measuring range is small, and the measuring range is 0-200GU. During the measurement, there is no need to manually press the button, that is, the measurement is displayed immediately.

The biggest difference between LS192 and LS191 gloss testers is the large range, the measurement range is 0-1000GU. The data of Linshang gloss tester and German BYK gloss tester are basically the same. The biggest feature of Linshang gloss tester is that it has an intelligent statistical function. When measuring, the insteument can automatically count the maximum, minimum, average and standard deviation of the data. Through statistics, the gloss uniformity of materials at different positions can be quickly and easily analyzed. The instrument can also operate online with the computer and print test reports.