Effect of Water-based Varnish Properties on Gloss

Everyone should know that water-based varnish is a liquid that uses water as a carrier and is applied online by a printing machine or offline by a glazing machine to increase the gloss, water resistance and abrasion resistance of paper prints. It is a environmental friendly product. Its solvents are mainly water and some alcohols. Its volatiles will not pollute the environment. Water-based varnish has gradually developed in recent years as people's environmental protection calls have increased. At present, its technology is not mature enough. The main problems are the poor surface finishing effect and the gloss can not reach the desired effect.

The coating process of varnish is essentially the process of varnish leveling and drying on printed matter. There are many factors that affect the gloss of water-based varnishes, such as the appearance quality of the material being coated, the coating process, the quality of the equipment and the varnish itself. Here we mainly discuss the performance of water-based varnishes on the gloss.

1. Effect of leveling on water-based varnish gloss

The leveling property of water-based varnish is another important factor that affects its gloss. It is affected by the viscosity and pH of the varnish. If the varnish has good leveling ability, it can be leveled quickly before the coating is dried to form a smooth surface. The coating will have high gloss; if the varnish cannot be dried before leveling, It will leave some streaks, trachoma, etc., which will reduce its gloss.

2. Effect of viscosity on water-based varnish gloss

The viscosity of the water-based varnish has a very important influence on the coating suitability such as leveling and wetting during the coating process. This is because the surface of the printed matter has a certain absorption to the varnish. The absorption rate of the printed surface to the varnish is proportional to the viscosity value of the varnish.

If the viscosity value of the varnish is too small, it will cause the viscosity change of the varnish during the leveling process when coating high-absorption paper. At the initial stage, its viscosity can still meet the leveling requirements. However, in the middle and late stages, the viscosity of the varnish has increased significantly. It is difficult to meet the leveling requirements. As a result, the leveling ends prematurely, causing uneven coatings on the surface of the printed matter. Some local lacquers affect smoothness and gloss of the film after drying and calendering.

If the printed matter with low absorption rate is applied, the viscosity is too low. A sag phenomenon will occur, leading to problems such as uneven coating and poor drying. If the viscosity is too high, it can not meet the leveling requirements and cause the premature end of the leveling and the gloss will deteriorate.

3. Effect of pH on water-based varnish gloss

The pH of water-based varnish is mainly adjusted by ammonia water. Generally, the pH of water-based varnish should be controlled between 8-9. If the pH value is too high and the alkalinity is too strong, the viscosity of the varnish will decrease, affecting the gloss. At the same time, the drying speed will be slower and the water resistance will be worse; when the pH value is too low, the alkalinity will be too weak, the viscosity will increase. Ammonia water volatilize too fast in the leveling process, so that the leveling ends too quickly, affecting gloss.

4. Gloss detection with specular gloss meter

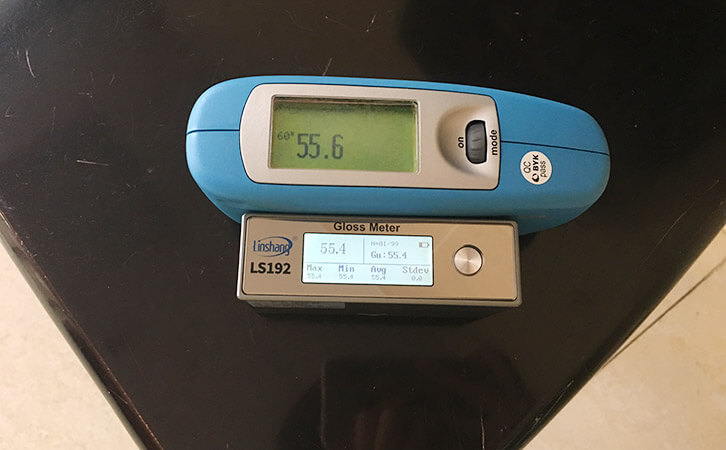

When it comes to the specular gloss meter in the industry, there is a well-known brand in Germany -Germany BYK specular gloss meter. We have to say that the German BYK was successful. The specular gloss meter was defined for the first time and became a unified standard instrument at home and abroad. Therefore, the BYK specular gloss meter price is not cheap, ranging from 10,000 to 30,000 RMB.

Now Linshang Technology has launched a specular gloss meter LS192, the first instrument can be compare with the German BYK specular gloss meter. The LS192 specular gloss meter has the following functions:

●Various measurement modes of the instrument, automatic measurement and manual measurement.

●Real-time measurement.

●It can display real-time value, maximum value, minimum value, average value, standard deviation. The smaller the standard deviation, the more uniform of the object gloss.

●Ultra-small design, take it with you wherever you go and measure where you go.

●The number of storage groups can be set by yourself and a maximum of 99 sets of data can be measured.

●The instrument meets the national metrological verification regulations JJG 696 level gloss meter standard.

●Connect to the computer, expand more functions and output professional reports in real time.