What are the Factors that Affect the Gloss of Plastics?

Plastic is another kind of high-molecular material that is artificially synthesized by many materials through chemical means. A product that can be arbitrarily kneaded into various shapes as desired and can finally maintain the same shape. It is also widely used in various industries. Plastic has the advantages of low manufacturing cost, shiny, light weight, insulation, corrosion resistance, strong plasticity and so on.

1. What factors will affect plastic gloss?

As a common industrial raw material, plastic is widely used in many industries. Such as plastic outer packaging, plastic daily necessities, plastic household and so on. Plastics are mainly composed of various synthetic resins, fillers, plasticizers, stabilizers, lubricants, colorants and other additives. Due to the different characteristics of raw materials and the differences in production processes, plastic products will produce a variety of luster. Plastic glossiness refers to their surface's ability to specularly reflect light. It refers to a physical quantity that evaluates the ability of a material's surface to reflect light under a set of geometrically prescribed conditions. It has a reflective property of direction selection. It is often measured using a professional gloss meter.

2. What is the general gloss of plastic?

The refractive index range of plastic is approximately 1.4 ~ 1.6 GU and the gloss is generally within the range of 70 ~ 110 GU.

The main factors affecting the gloss of plastics are the following:

(1) The influence of raw materials on the surface gloss of products

The characteristics of the resin itself have a great influence on the gloss of the product surface, which is an effective method for controlling gloss.

(2) The influence of processing technology on the gloss of plastic surface

For molded products, a surface-polished mold can be used to improve gloss of the mold to adjust gloss.

(3)The effect of filler on the gloss of plastic surface

Inorganic filler filled plastic products can impart high rigidity, heat resistance and dimensional stability, reduce production costs. Most inorganic fillers will seriously affect the high gloss of the clinker itself.

3. Why do we test the gloss of plastics with 60 degree gloss meter?

Some products need to show the surface metal texture realistically, so the polymer morphology on the metal surface needs to be changed in advance to make plastic products with various gloss characteristics on the surface. Some plastics tend to be directional due to their different forming methods and their gloss is also different. Such as the ceiling lampshade and embossed lampshade used for lighting, the material's transparency and opalescent properties will affect the gloss of the material.

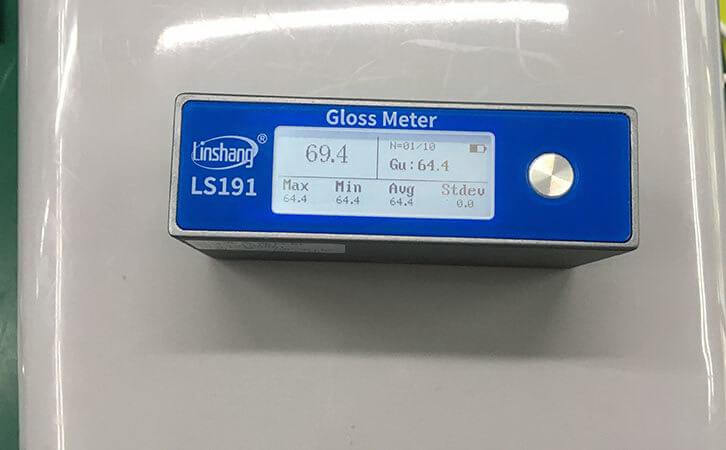

The purpose of testing the gloss of plastic is to evaluate the quality of the product based on data inspection and to indicate whether the production conditions are related to the surface gloss of the material. We can use the 60 degree gloss meter LS191 to measure and evaluate the gloss of plastics.