How to Measure Gloss of Injection Plastic? | Gloss Checker

Sometimes the plastic surface of injection molding will appear dull, or the gloss and color are not uniform. We can use the gloss checker to measure the gloss.

The production of plastic requires petroleum resources, which are non-renewable resources. It is everyone's responsibility to produce high-quality plastic products with limited resources. And sometimes the plastic surface of injection molding appears dull, or the gloss and color are uneven. Why is this? For this phenomenon, we summarized the reasons and solutions.

-

The injection speed of the injection molding machine is too fast and the material retention time is too long, which will cause the surface gloss of the injection molded products to decrease;

Solution: reduce the injection speed of the injection molding machine and reduce the residence time of the material.

-

Moisture absorption or volatile matter in raw materials is a common cause of poor surface gloss of plastic products.

Solution: dry the material before use and add a dryer if necessary.

-

Excessive use of mold release agents will also cause such defects on the surface of plastic products.

Solution: Try not to use or just use a small amount of release agent and apply evenly.

-

The quality of the product raw materials has a greater impact on the surface gloss of plastic products. Only the inclusion of impurities will reduce the surface gloss of the product.

Solution: Use high-quality raw materials or remove impurities before use.

In addition to the above methods, common additions include processing such as additive brightness enhancement, blending brightness enhancement, morphology control brightness enhancement can improve the surface gloss of plastic products.

Surface gloss testing of plastic products

Some products need to show the surface metal texture realistically, so the polymer morphology on the metal surface needs to be changed in advance to make plastic products with various gloss characteristics on the surface. Some plastics tend to be directional due to their different forming methods and their gloss is also different. Such as the ceiling lampshade and embossed lampshade used for lighting, the material's transparency and milky properties will affect the gloss of the material.

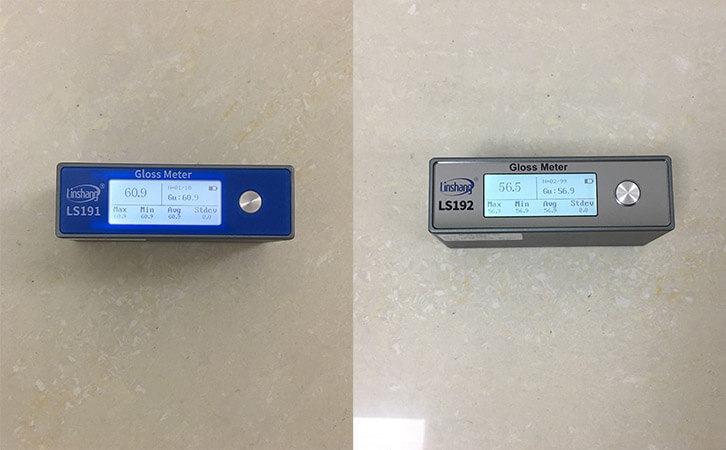

Use gloss checkerto measure plastic gloss value

The purpose of testing the plastic gloss is to evaluate the quality of the product based on data inspection as well as indicate whether the production conditions are related to the surface gloss of the material. The refractive index range of plastic is approximately 1.4 ~ 1.6 GU and the gloss is generally within the range of 70 ~ 110 GU. A 60 ° gloss meter LS191 can be used to measure and evaluate the gloss of plastics.