UV Power Puck and UV Curing Technology

The UV curing technology is widely used. UV curing of optical and electronic parts, UV curing of coating agents, UV curing of printing inks and coatings are common.

1. UV curing of optical and electronic parts

UV-curable resins with fast curing properties can be quickly cured and air-dried under the irradiation of ultraviolet rays. They are often used as adhesives in the production and repair of electronic and optical components. Because of its quick-drying and transparency and its significant advantages such as smaller volume after air-drying, it is also popular with manufacturers. The specific parts are camera lens; loudspeaker cone vibration plate and coil; circuit substrate; liquid crystal panel and automobile engine internal parts.

2. UV curing of coating agent

Automotive or other vehicles; building materials; surface coating drying and protection of electrical appliances or plastics, as well as coating curing and drying that produce gloss, can be applied to UV curing technology. Specific items are automobile body and headlight lenses; plastic lenses for eyes; furniture; mobile phones; metal switches and floor tiles.

3. UV curing of printing inks and coatings

In order to speed up printing speed and increase production capacity, UV curing technology is generally used to accelerate drying. Specific examples are beverage cans; cosmetic bottles and compact discs. In addition, printing a large number of items, such as credit cards; toothpaste shells; machine switches, etc. In these industries, we can also use UV curing technology.

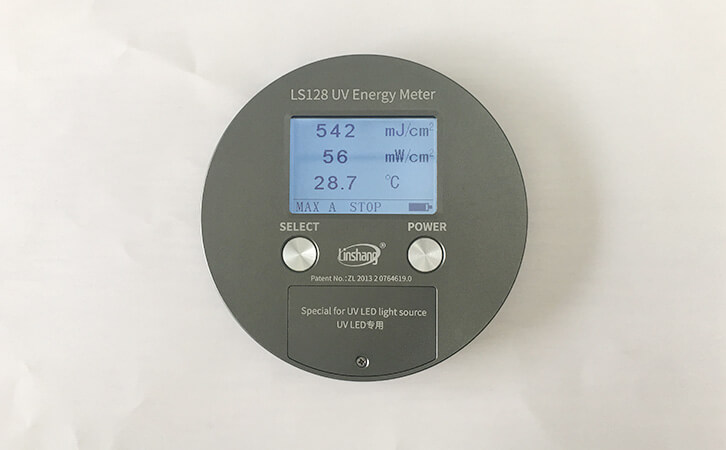

Although UV curing technology is very easy to use, it also needs a standard to measure whether the technology passes the standard. At this time, the UV power puck plays an important role. UV power puckcan detect the ultraviolet intensity of ultraviolet light, whether the ultraviolet power and the irradiation time are properly controlled. Some instruments can display real-time power, maximum power, capacity value and test duration at the same time during the test. It can even connect a computer through an interface to export test data for printing and backup.

At the present stage, UV curing technology and UV power puck can be said to be inseparable. More accurate detection will drive the technology to improve. The UV power puck independently developed by Linshang Technology can not only measure UV energy, but also measure UV power and time. Linshang UV power puck can monitor UV curing technology.