How does Paper Smoothness Affect Product Gloss?

1. How to determine the smoothness of the paper surface?

The surface smoothness of the paper is measured by the air leakage method: the time required for a certain volume of air to pass through a gap between the paper and glass under a certain pressure in a certain area of paper. The second (s) is the unit of calculation. Judging from the quality standards of coated paper published by China in the past few years, the smoothness of 150g / m² special double-sided coated paper is 500s, while the coated paper of the same quantity abroad has a smoothness of more than 1000s. In 1986, Shanghai Jiangnan Paper Mill introduced a production line of 150g / m² advanced fine art coated paper with a smoothness of 1000 ~ 1500s, which is one of the domestic papers that have reached the highest standard of smoothness.

2. Effect of paper surface smoothness on product gloss

The surface smoothness of various papers is different and the level of smoothness has a greater impact on the gloss of the finished product. The paper with high smoothness has good contact with the ink, which can ensure the complete reproduction of the dots. Then the finished product have better gloss. Because the gloss of the ink film on the paper depends on whether the incident light can be specularly reflected, only the smooth paper can have specular reflection after the ink film is leveled. On the other hand, the smoothness is poor, the rough surface of the paper imprinted ink film is uneven. It can only form diffuse reflection of light and the finished product has no gloss. Therefore, for exquisite and high-quality products, to obtain better finished gloss, we must first use high-smooth paper for printing.

3. Product gloss measurement method

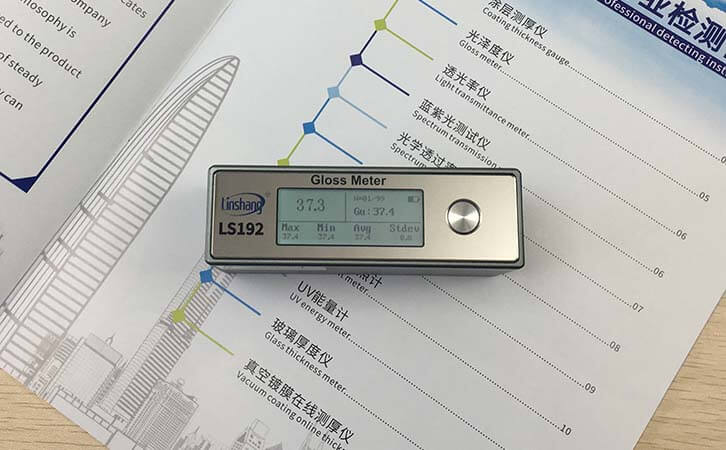

Gloss is related to the ability of the surface to reflect light. Because there are too many influential factors on the subjective evaluation of gloss. In the industrial production process, if you want to accurately evaluate the gloss characteristics of products, you need to refer to certain standards. Generally, Linshang LS192 gloss checker is used to measure the specific gloss of the product surface.

4. Operation method of LS192 gloss checker

The LS192gloss checker has only one power button. Press the power button to turn it on and you will be prompted to perform a calibration after turning on the power(in general, the error within ± 0.5GU is not recommended for calibration). Then enter into the test interface. The interface can display real-time value, current record value, maximum value, minimum value, average value, average difference value and number of tests and statistics. After the test is completed, simply close the instrument to the base of the standard board and it will automatically shut down.

These is no need to press the button when testing, just put the instrument on the tested material. If you want to record the test data, you can press the power button for each measurement.