Energy-efficient UV LED Plane Light Source | UV LED Power Puck

UV LED Plane Light Source has many outstanding features such as energy saving and environmental protection. In order to ensure the normal operation of the LED light source, we usually use a UV LED power puck to detect its intensity and analyze the distribution of the Plane Light Source.

1. Advantages of UV LED Plane Light Source

In the past, the cooling surface of traditional high-power light sources was small, that is, there were a large number of radiators that could not quickly output heat, so the light would quickly decay. UV LED Plane Light Source has a relatively large cooling surface, and its service life is generally between 25,000 and 30,000 hours. The service life is not affected by the number of times the light source is turned on and off. Instead of using traditional light sources that need to be replaced frequently, choose a more energy-efficient UV LED light source. However, with the increase of the use time, the LED light source will also have a certain degree of attenuation. Therefore, most users of LED light sources use a professional instrument UV LED power puck to detect the intensity of the UV LED light source.

UV LED light source has good light output stability, high intensity, high energy, good uniformity, and can emit light instantly. The UV output power can reach 100%, the intensity can reach 1200mW / cm2 (depending on the wavelength), and the effective luminous efficiency is 10 times that of the mercury lamp, which greatly improves the working efficiency. UV LED light source can be customized according to the needs of the shape and size of the light-emitting area. UV LED light sources do not require pre-heating in advance and do not contain toxic mercury. The traditional UV light source needs to be pre-heated for about 10 minutes before use and contains toxic mercury. Therefore, UV LED Plane Light Source is a choice that meets more energy-saving and environmental protection requirements.

Common UV LED light sources include 365nm, 395nm, 405nm and so on. UV LED light source irradiation does not cause the product surface temperature to rise too much. The light source used by a conventional ultraviolet irradiation machine usually irradiates the product surface to increase its temperature by 60-90 degrees. If the position of the UV irradiator is changed, uneven product exposure will result in substandard product quality.

2. UV LED power puck for professional detection of UV LED Plane Light Source

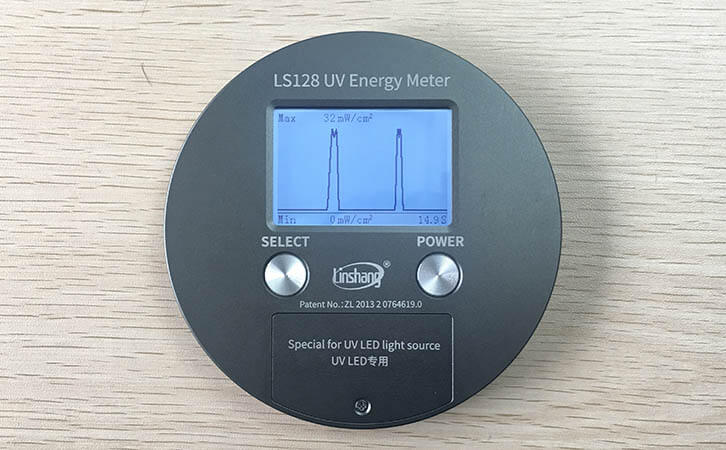

LS128 UV energy meter

In order to improve work efficiency and better industrial production, a professional UV LED power puck can help us measure the intensity of LED light sources. If the intensity of the light source is unsatisfactory, you can increase or decrease the power of the light source according to the production needs, or you can slow down the conveyor to make the product receive longer exposure time.

Linshang LS128 UV LED power puck is the world's first professional UV LED power puck for measuring LED light sources. It is specially designed for the spectrum of LED light sources and is suitable for measuring a variety of LED light sources. This UV LED power puck can measure the intensity of the light source and the temperature at the time of curing. It can also display the temperature curve and power curve. The user can analyze the intensity distribution of the LED Plane Light Source through the power curve. Find out the problematic light source through the curve. If the curve shows a sudden drop in power, it means that the light source at this location has a problem and needs to be replaced. For more details about UV LED power pucks, please contact us in time.