Brief Introduction and Application of UV and UV Energy Tester

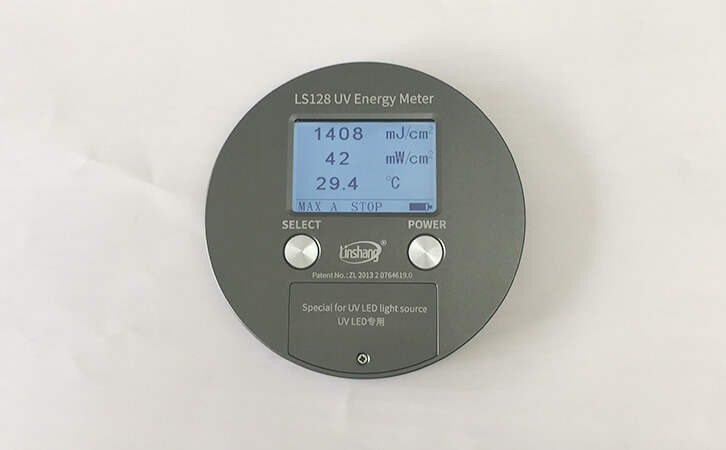

UV is ultraviolet, a section of electromagnetic radiation other than violet, with a wavelength of 10-400nm. Industrial production generally uses long-wavelength UV. At present, there are two main applications of UV in the industrial field: UV curing and UV sterilization. UV curing is the use of UV to irradiate the coating, resulting in radiation polymerization, radiation crosslinking and other reactions. A chemical process that rapidly converts low molecular weight materials into high molecular weight products. UV sterilization is mostly used in the field of food and materials. Because of its strong sterilization ability, high efficiency, and does not cause traditional pollution problems, it is widely used. A UV Energy Tester is an instrument used to measure UV light sources. By making the detector of the energy meter sense the light source, it can measure the UV intensity and provide guidance for the use of UV light sources in the production field.

1.UV printing

UV printing is an application of UV energy. Compared with traditional processes, the surface of UV printing products is well protected and is not easily damaged during the production process. And the UV drying system on the printing machine makes the printing process simple and efficient, the drying process is fast, the loss is small, the ideal control of the product can be achieved, and the printing speed and quality are greatly improved.

UV printing is suitable for printing special materials, such as PVC plastic sheet, waterproof material, etc. This printing technology is widely used in hot stamping, laminating, and embossing. In the process of using UV printing, it is necessary to control the UV energy index by means of a UV Energy Tester to cure the UV ink to a better level.

2. UV printer

UV printers use UV waves emitted by LED lamps to cure UV inks. They can rely on the piezoelectric effect inside the nozzles to precisely control the instrument without contacting the material. UV inks do not contain volatile solvents and do not pollute the human body and the environment. But the ink cannot see the light, because the photocoagulant contained in the ink will chemically react with the ultraviolet light in the light to cure. Different from the heating and drying in the traditional printing process, the ultraviolet method can be used to achieve rapid curing and no fading. In this process, the energy value of the UV light source needs to be recorded by a UV Energy Tester.

3. Other applications of UV

The radiant heat generated by the UV lamp can accelerate the reaction speed of light curing. The stronger the radiation intensity in the wooden floor, UV coating of metal products, UV insulation coating of printed circuit boards, and UV bonding of glass products to the production process The greater the effect. However, for workpieces that are sensitive to temperature or poor in temperature resistance, such as printed computer keyboards, printed paper and plastic sheets, UV radiation heat will cause great damage to the product, reduce the service life of the product and affect the final product. Effect, even "waste", etc., in the use of UV lamps for industrial production, the role of UV Energy Tester is very important. Only by reading the UV Energy Tester and controlling the UV intensity in an appropriate range can the production process of the product be more perfect.

During the use of the UV Energy Tester, pay attention to maintaining the stability of the instrument, try to fix it on a stable plane and keep it still. After use, close the instrument in time, store it in the original environment to prevent damage to the instrument and affect accuracy. Avoid direct contact with the UV light source as much as possible during the measurement process. If necessary, use protective equipment to prevent the skin from being damaged by strong light radiation. The instrument should be stored in a closed and cool space and kept at normal temperature.

The UV Energy Tester can accurately read the UV energy index, making the UV technology better used. The application of UV technology in the fields of UV curing and UV sterilization has improved production efficiency and product quality, is conducive to protecting the environment and improving energy efficiency, and has reduced production costs for enterprises.