Influencing Factors of Curing Time of UV Glue and Selection of Ultraviolet Energy Meter

Glue is used most of the time in daily life. We also know that the curing speed of glue is relatively fast. Under a certain wavelength of ultraviolet radiation, it only takes a few seconds to quickly dry. In fact, in the practical use of daily life, the curing time of UV glue will also be affected by different factors. We can use Ultraviolet energy meter to determine different optimal glue curing processes. Let's find out today!

The factors that influence the curing time of UV glue are mainly divided into two major parts, namely internal factors and external factors.

1. External factors

The curing rate, final curing depth, and dryness of the surface of the UV curing adhesive are related to a series of factors such as the UV light source, the irradiation time, and the light transmittance of the material.

First, let's talk about the relationship between UV curing glue and the power of UV lamps. If the power of the UV lamp is high, the curing speed is fast; if the power of the UV lamp is small, the curing polymerization speed is slow. Generally, UV glue is cured by UV lamp irradiation. Under UV lamp with relatively low rated power, the curing time of UV glue will become longer. On the contrary, under UV lamp with relatively high rated power, the curing time of UV glue will be reduced. You can use a Ultraviolet energy meter to accurately measure the intensity and energy of ultraviolet light.

Secondly, the curing time of UV glue is closely related to the light transmittance of its own material. If the curing glue itself is easily penetrated by ultraviolet light, its curing time will be faster; if it is not easily penetrated by ultraviolet light, its curing time will be extended. If it is difficult to penetrate ultraviolet materials, there may even be May not complete curing.

2. Internal factors

The internal factors of UV glue also determine its curing time. You must know that the photoinitiator is one of the main ingredients that must be present in any UV curing system, because it plays a decisive role in the curing rate of the UV system. In different formulations of UV glue, the proportion of the photoinitiator will affect curing effect.

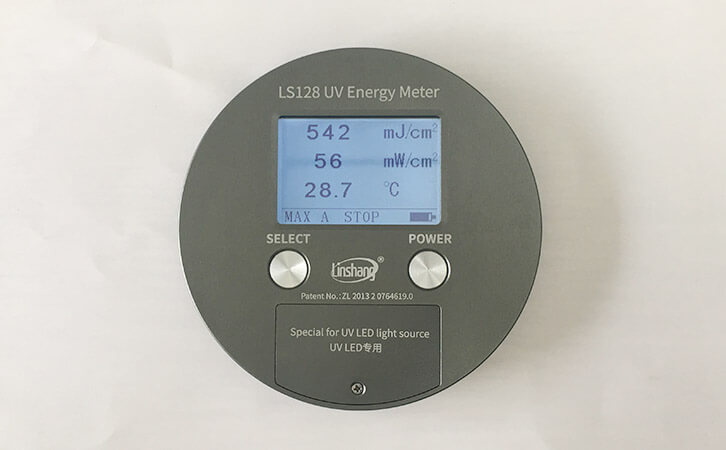

Picture (LS128 measurement data display)

3. Selection and use of Ultraviolet energy meter

The selection of UVLED lamps and inspection and maintenance after use are one of the main conditions to ensure the maximum efficiency of UV light curing! After choosing and purchasing UVLED lamps, you can use Linshang LS128 Ultraviolet energy meter to determine the curing process. The spectral response range of the LS128 UV LED energy meter on the forest is 340nm-420 nm, so the test UV LED lamp is OK in any band in the spectral range, and the consistency and stability of the instrument are good. Using the forest LS128 Ultraviolet energy meter is an indispensable tool for selecting UVLED lamps, and it is also the best partner for measuring the UV light intensity and energy of UVLED lamps in the later stage!