Thickness requirements of aluminum alloy paint | Coating Thickness Gauge

Electrostatic spraying is the common way of spraying aluminum veneer, the surface can have a variety of treatment, one is fluorocarbon spraying, one is powder spraying, one is polyester spraying, different spraying on the quality and performance of aluminum veneer has different effects, the thickness of different paint film is a certain standard, choose a different coating process, with the naked eye can not distinguish the difference, the difference is the difference in life, of course, the cost is also Different, aluminum veneer customers according to the project needs and cost discretion to choose. About the thickness of the paint layer, in fact, many aluminum veneer customers often enter a misunderstanding, thinking that the thicker the paint the better, but not, even if the quality of the paint film is not a problem, if the paint film is too thick or too thin, the long-term quality of aluminum veneer have an impact. The following gives you an introduction to the thickness requirements of aluminum alloy paint film.

What is the general thickness of baking paint?

It is very important to measure the thickness of the paint film in order to have a certain protection capacity. The thickness can be measured either immediately after painting the wet film or after drying. The measurement results are used to correct the coating conditions to achieve the specified thickness range. The thickness of the paint film of aluminum alloy baked parts produced by different manufacturers is different, and can be changed according to the use of different environments. For example, the thickness of powder coating for outdoor parts should be 100~150μm.

Paint coating film thickness standard criteria

Paint coating of different nature, the paint film thickness will be somewhat different, here are a few reference thicknesses for you:

General coating is 30-40 microns.

Decorative coating is 35-45 microns.

Protective coating is 125-130 microns

130-150 microns for abrasion resistant coatings

700-1000 microns for thick coatings with high solids content.

Generally speaking, the same thickness of paint film in multiple layers is much more excellent than the protection ability of a single coating. Nowadays, the general parts of steel beams are sprayed with primer and topcoat twice, and the total thickness of dry film is 150-200 microns, i.e. 40-50 microns. Individual vulnerable to damage or difficult working conditions should also increase the paint degree, so that the total thickness of the paint film thicker.

Aluminum baking paint film thickness detection method

Aluminum baking paint is different from the above paint spraying, its paint film thickness control is more strict, in order to help users nondestructive testing of aluminum baking paint film thickness, you can use eddy current method thickness measurement.

Eddy current thickness gauge belongs to a non-destructive testing instrument, that is, the thickness of the material in the case of non-destructive material thickness measurement instrument, eddy current thickness gauge through the probe from the material of the single-sided contact measurement of the thickness of the material. Thus avoiding the calipers, micrometers, gauges, etc. need to be stuck from both sides to measure the thickness of the disadvantages of the advantages of nondestructive testing, and thus widely used in plate manufacturing, pipeline corrosion, electroplating and painting, mechanical parts manufacturing, aerospace and other important fields.

Eddy current thickness gauge favor surface cladding measurement, can be used to measure the thickness of coatings on metal, anti-corrosion layer, electroplating layer, plastic, paint, plastic, ceramics, enamel and other cover layers, so the formal naming of the national standard for cladding thickness gauge. Can also be extended to the application of indirect measurement of the thickness of paper, film, plate, etc.. Eddy current thickness gauge accuracy is relatively high generally in μm as a unit, display resolution can reach 0.01μm, 0.1μm, 1μm and other precision. Non-iron-based eddy current thickness gauge with eddy current sensor to measure copper, aluminum, zinc, tin and other non-ferrous metal substrates on the enamel, rubber, paint, plastic layer, etc..

Use eddy current thickness gauge for aluminum alloy baking paint film thickness test, first to zero and calibrate the instrument, meet the requirements, immediately after the probe perpendicular to the specified part of the specimen, then the value indicated on the table head, that is, the specimen of the part of the coating thickness value. Then repeatedly measure several times in the nearby parts, and when the value is close, take the average value of each point as the average thickness of the coating.

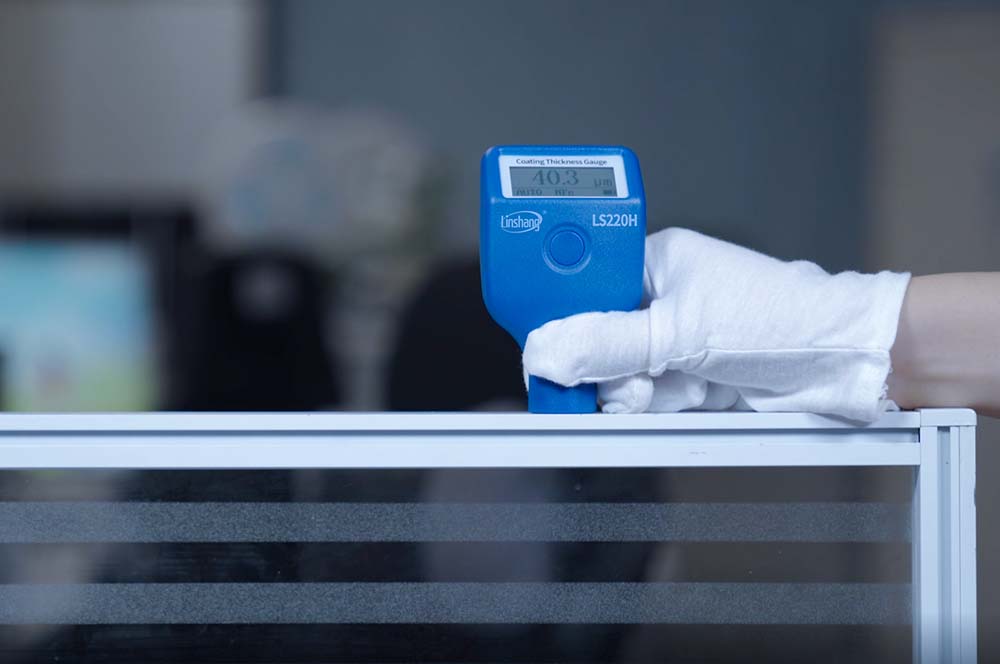

There are relatively many coating thickness gauges on the market, but in terms of cost-effectiveness and instrument function, we recommend Linshang coating thickness gauges. The Linshang coating thickness gauges mainly divided into 5 models: LS220H, LS221, LS223, LS225+ F500, LS223+ N1500. These five instruments are different and users can choose according to their needs.

- High precision coating thickness gauge for used car

- Automotive paint protection films coating thickness gauge

- Plating Thickness Measuring Instrument for Detecting Anti-corrosion Coating

- Linshang LS220, LS191, LS160A– Necessary for Car Cover Inspection

- Coating Thickness Gauge for Second Hand Vehicle

- Zero Adjustment Step of Coating Thickness Gauge