Surface Treatment of Plastic Products and Its Gloss Detection

The surface treatment of plastic products mainly includes coating treatment and plating treatment. Generally, the crystallinity of plastic is large, the polarity is small or non-polar and the surface energy is low, which will affect the adhesion of the coating. Since plastic is a non-conductive insulator, it cannot be coated directly on the plastic surface according to plating process specification. Therefore, before the surface treatment, the necessary pretreatment should be performed to improve the adhesion of the coating. The coating provides a conductive bottom layer with good adhesion.

1. Pre-treatment of coating

The pre-treatment includes degreasing treatment of the plastic surface, that is, oil stain and mold release agent for cleaning the surface and activation treatment of the plastic surface. The purpose is to improve the adhesion of the coating.

(1) Degreasing of plastic products

(2) Surface activation of plastic products

Among them, the chemical crystal oxidation treatment method is most widely used. This method commonly uses a chromic acid treatment solution. Its typical formula is 4.5% potassium dichromate, 8.0% water, and 87.5% concentrated sulfuric acid (more than 96%).

Some plastic products, such as polystyrene and ABS plastic, can also be directly coated without chemical oxidation treatment.

2. Pretreatment of plating

The purpose of the plating pre-treatment is to improve the adhesion of the plating to the plastic surface and to form a conductive metal bottom layer on the plastic surface.

The pretreatment process mainly includes: mechanical roughening, chemical degreasing, chemical roughening, sensitization treatment, activation treatment, reduction treatment and chemical plating. The first three items are to improve the adhesion of the coating and the last four items are to form a conductive metal bottom layer.

3. Surface gloss testing of plastic products

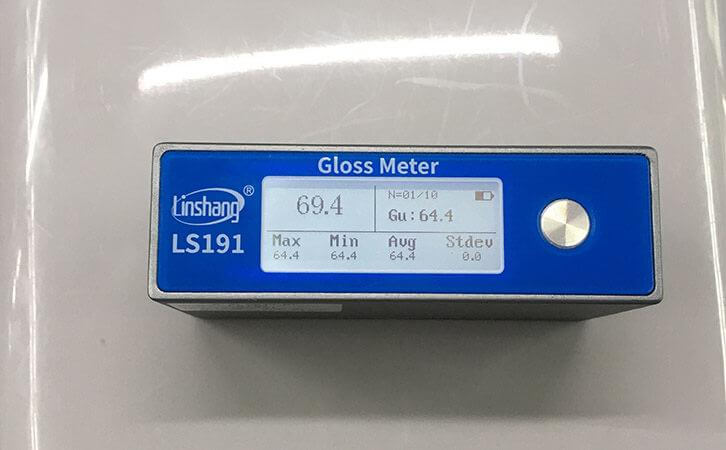

The purpose of testing the plastic gloss is to evaluate the quality of the product based on data inspection and to indicate whether the production conditions are related to the surface gloss of the material. The refractive index range of plastic is approximately 1.4 ~ 1.6 and the gloss is generally within the range of 70 ~ 110 gloss. However, the reflective conditions of transparent plastics and translucent plastics are different and cannot be generalized. A 60 ° gloss meterLS191 can be used to measure and evaluate the gloss of plastics.

Linshang LS191 Gloss Meter is a general-purpose instrument that can be used to measure the gloss of plastic products and evaluate the quality of the product based on data inspection.