Factors Affecting UV Radiation Curing | UV Integrator

After UV coating is irradiated with UV light, the photoinitiator is triggered to produce free ion groups or ions. These free radical ions crosslink with the double bonds in the prepolymer or unsaturated units to form monomer genes. These units Genes start a chain reaction to generate polymer solid ion molecules and a complete curing process ends. Let's talk about several factors affecting its deep curing and the choice of UV integrator.

1. UV energy

The deep curing of ultraviolet radiation is mainly based on the fact that the molecules must absorb light quanta with sufficient energy to become excited molecules, decompose into free radicals or ions and allow unsaturated organics to polymerize, graft. Cross-link chemical reactions can achieve the purpose of curing. The UV light energy of the photoinitiator in the supplied UV coating exceeds or is less than its required energy, such as:

(1) It is known that the ultraviolet light energy required by the photoinitiator is to be completely solidified. The energy supplied is reasonably greater than the energy required by it is normal.

(2) I don't know the ultraviolet light energy required by the photoinitiator, blindly over-supply. This method not only wastes energy, but also causes negative effects of excessive curing, such as explosion polymerization and anti-curing reactions.

(3) When the energy of ultraviolet light is insufficient, the energy of ultraviolet light must be moderate, that is, neither excessive nor insufficient, so as not to cause complete curing. During this period, we can use a UV integrator to determine whether the light source is still effective and the uniformity of the light source.

2. UV Coating Thickness

The UV coating thickness plays a key role in the effect of UV curing. The coating is too thick and the drying time is relatively long under the same power light source. On the one hand, it affects the drying of the UV coating. On the other hand, it will make the substrate surface temperature too high. In addition, the UV coating thickness, the hue of the coating, the temperature, the curing speed and the surface of the substrate need to be properly adjusted under different conditions.

3. Effect of distance

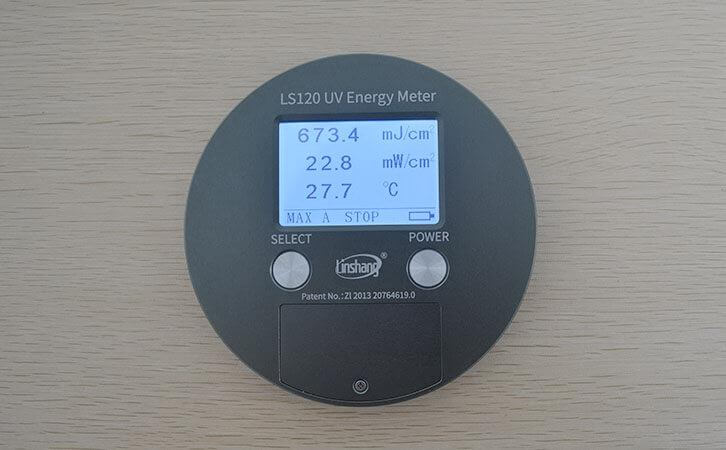

7-8cm is the best distance between the UV lamp and the reflector and the surface of the illuminated object. But according to the curing substrate, the distance is generally about 10-15cm. The curing distance must be adjusted appropriately considering the factors such as the substrate, coating, lamp power, etc. You can also directly use the UV integrator LS120 to determine the optimal curing distance of the light source.

4. Effect of curing speed

Depending on the substrate, coating, curing distance, etc., the curing speed of the equipment is appropriately adjusted. If the curing speed is too fast, the UV coating on the substrate surface is sticky or the surface is dry and the running speed is slow, the substrate surface will age.

5. Impact of Working Environment

UV coatings have large changes in viscosity due to temperature, so room temperature should be adjusted. 15-25 degrees Celsius would be more suitable. To sum up: In the practice process, we should continuously summarize experience and master it flexibly according to the actual situation, so that it has better adaptability.

6. Importance of UV curing machine light source intensity detection

The commonly used UV band is divided into four bands: UVA, UVB, UVC and UVV. It is very important to choose a suitable light source and curing time for the ultraviolet spectrum. The more commonly used is the UVA band. That is, the peak wavelength is 365nm. The response wavelength of the glue must be in the same wavelength band as the UV light source. Otherwise, the curing is of little significance. If you want to improve the curing efficiency, you need to consider the power intensity of the UV curing machine, the duration of light and temperature. Selecting suitable parameters is a necessary condition for high-efficiency curing.

There are many factors that affect curing, which has spawned a lot of equipment around the UV curing industry. Among them, the intensity of the light source is particularly important. The UV light source will decay after using it for a period of time. At this time, a UV integrator will be used to determine whether the light source is still effective.

UV integrator LS120 can record the intensity value and temperature value of ultraviolet in real time. During the measurement time up to 4 minutes, a total of 6W data are recorded. The situation inside the curing oven can be seen very clearly. You can also connect the computer and print out the data.

Different sizes of objects need to be cured, resulting in different types of curing machines. The light sources are different and the wattage is also regulated, but the UV integrators used are all the same. You just need to choose the UV integrator according to the corresponding waveband.