Factors Affecting UV Ink Curing and Selection of UV Energy Meter

1. Effect of pigment on curing

In order to meet the needs of high-end printing, it is not enough to rely on the three primary color inks. Spot color inks are needed. However, for UV inks, some pigment particles will compete with the photoinitiator or photosensitizer for incident UV radiation energy. This affects the latter's absorption of radiant energy, so that the ultraviolet light irradiated onto the UV ink surface cannot be transmitted directly. The UV light can only pass through the above pigment particles to the bottom of the ink layer after multiple reflections and light scattering, which slows down the drying speed.

Thorium contains thousands of pigment particles in UV inks. Therefore, UV light must have sufficient intensity to reach the bottom of the ink layer. If the light intensity is insufficient and the bottom of the ink layer is not irradiated with ultraviolet light, the ink cannot be completely cured, causing the ink layer to be hard outside and soft inside. The surface shrinks due to the volume shrinkage during polymerization, which affects the printing quality. We use a UV energy meter to periodically inspect the UV light source of the curing machine. Prevent defective products caused by curing time or curing energy not meeting the standard. At the same time, it should be noted that the curing of UV ink is different from the curing of UV varnish. In addition to affecting the curing of UV inks, pigments can also affect the viscosity, flowability, wettability and leveling of the ink layer; The interaction between pigments and reactive binders can lead to a decrease in ink storage life or problems such as color changes.

2. Pigment color and curing

When using certain yellow pigments in a photo-initiated system composed of acrylates and amines, the ink color will change greatly. The more difficult to cure pigments are black, white, phthalocyanine and yellow pigments. White and black exhibit two extreme phenomena, white reflects light completely and black does not reflect light at all.

It is even thought that it may not be possible to pass UV light through a film layer of a certain thickness and opaque to the light, but optimizing the curing conditions will make possible the good curing of UV inks containing pigments. Some problems can be solved or improved by selecting photoinitiators and pigments according to the absorption characteristics of pigments by UV light. We can also periodically detect UV light sources by UV energy meter and adjust the UV light source in time to reduce the effect of curing pigments.

Different pigments have different absorption, reflection and scattering characteristics of light, so they have different degrees of resistance to UV curing. Most pigments have a certain transmissive area in some UV and visible light ranges. "Spectrum window", in which the photoinitiator can fully absorb the radiant energy of UV light. Therefore, determining the window position is very important to select the appropriate photoinitiator. That is, the photoinitiator should match the pigment in the ink system and be in the wavelength range where the pigment absorbs UV light weakly. Therefore, when using UV inks, you should carefully observe the relationship between the absorption spectrum of the pigment and the photoinitiator. You can also use a UV energy meter to detect the intensity and energy of ultraviolet light.

The curing speed of different colors of UV inks is different, because the wavelengths of light waves reflected by pigment particles of different colors are different. The closer the reflected wavelength is to the wavelength of UV light, the slower the curing speed is. The higher the energy; conversely, the faster the curing speed, the lower the UV light energy required. We can use a UV energy meter to detect the level of UV light energy and adjust the UV curing speed to reduce the effect of pigments on ink curing.

3. How to choose a UV energy meter?

The measurement principle of the UV energy meteris to convert the weak current signal of the UV detector into a digital signal through an ADC analog-to-digital conversion chip. Then the digital signal is collected by the single-chip microcomputer and then adjusted by software. The time is integrated to obtain the UV energy value. The main components of the instrument are: sensor, display, central assembly, battery, control switch and protective shell. A UV filter film is installed on the sensor surface to obtain UV radiation in the specified UV band. The unit is millijoules per square centimeter (mJ/cm²).

4. So how to choose Linshang UV energy meter?

First we need to confirm the light source to be tested. At present, ultraviolet light sources are mainly divided into several curing light sources such as high-pressure mercury lamps, halogen lamps and LED lamps on the market. Because different light sources have different wavebands, the instruments used are also different. For high-pressure mercury lamps and halogen lamps, you can choose a UV energy meter (Linshang LS120) dedicated to the high pressure mercury lamp. Not only the energy, but also the power and temperature can be tested to easily analyze the stability and temperature changes of the lamps inside the curing furnace.

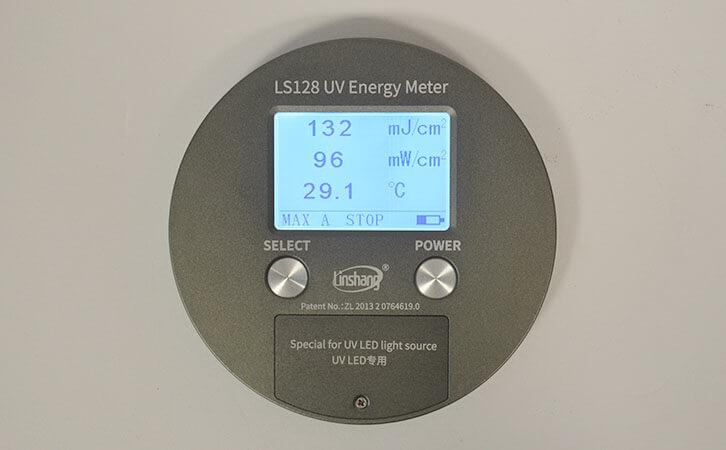

If the light source is an LED light source, a UV energy meter that is generally used for testing mercury lamps on the market is likely to be unsuitable. Therefore, it is recommended to choose the LED energy meter LS128, which can perfectly respond to all ultraviolet LED light sources in the range of 340nm-420nm. It can also test energy, power and temperature. The LS128 UV energy meter also has wide application in medical UV LED lamp industry.