UV LED Light Source and Dedicated LED UV Energy Meter

UV LED curing is becoming more common in the printing industry. UV LED light sources are widely used in printing machines due to their low energy consumption and high curing efficiency. However, as the use time increases, the LED light source will also attenuate. Therefore, we need to use a professional UV energy meter to detect the intensity of the light source. So what are the advantages and disadvantages of UV LED light sources? What kind of UV energy meter do we use to detect the intensity of the light source? Can all UV energy meters be used to detect LED light sources? Next, we will analyze each of the questions for you.

1. Advantages of UV LED light source

(1) Reducing energy consumption and improving effective luminous efficiency can reduce energy consumption by 70% to 80%.

(2) No ozone is generated during the curing process and the LED ultraviolet light source does not generate short-wave ultraviolet rays. Therefore, no ozone is generated during the curing process. No need for deodorizing devices, exhaust pipes and other auxiliary devices can maintain a clean working environment.

(3) More flexibility. LED UV light source uses point light source, can be arranged in a line or form a area light source to set the exposure range according to customer needs.

(4) The lamp can be turned on (off) immediately. Traditional UV light sources can only be activated after 1 minute of preheating and can be switched off after 4 minutes of cooling. To increase efficiency, many operators often keep UV lights on, which is wasteful. The LED UV light source can be turned on immediately when printing, which greatly improves work efficiency.

(5) Low heat generation. Used in UV LED exposure equipment, the photoelectric conversion efficiency is high, the surface temperature of the lamp tube is only about 60 °, which can effectively prevent printed materials from shrinking and deforming due to overheating, thereby achieving high accuracy.

(6) Long service life. The service life of LED UV light source can reach 20,000 ~ 30,000 hours, which is more than ten times of the existing high-pressure mercury lamp and metal halide lamp (1500 hours). It can greatly reduce the number of light source replacement.

2. Disadvantages of UV LED light sources

(1) The irradiation intensity is weak. If the printing speed is too fast, it may easily lead to incomplete curing of the ink.

(2) Only long-wave ultraviolet rays can be emitted and short-wave ultraviolet rays cannot be emitted, so it is not conducive to ultraviolet light curing.

(3) Energy-saving UV LED light sources used for spot curing are expensive.

(4) The reconstruction of the existing printing press is difficult. Due to the short irradiation distance of the LED UV light source, it must be close to the irradiation on the substrate surface. In order to ensure good ink curing, the modification of the existing printing machine has brought great inconvenience.

3. UV energy meter for UV LED light source intensity detection

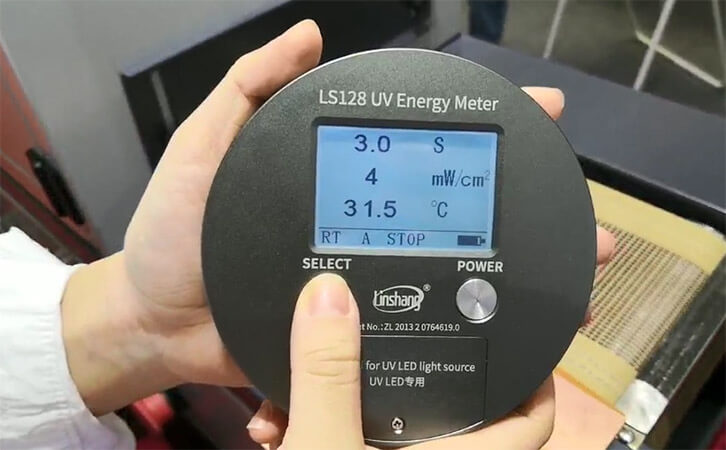

The UV LED light source intensity will decrease over time. If the light source does not reach the required intensity during curing, a good curing effect cannot be achieved and the product quality will be affected. Therefore, we need to use a professional UV energy meter to detect the intensity of the light source. So what kind of UV energy meter is suitable for detecting LED light sources? Most of the common UV energy meters on the market are instruments for detecting high-pressure mercury lamps. And the ultraviolet rays used for curing in high-pressure mercury lamps are mainly 365 nm. Therefore, the UV energy meter for high-pressure mercury lamps has the highest response to 365nm ultraviolet light. There are many types of LED light sources, 365nm, 395nm, 405nm are common and LED light source is a single wavelength of ultraviolet light. Linshang LS128 LED dedicated UV energy meterhas the same degree of response to 365-405nm LED light sources. This meter can measure multiple LED light sources. The spectral response range of this instrument is 340nm-420nm. Not only the intensity of the light source, but also the temperature during curing. With a measurement speed of 2048 times per second, it is the world's first UV energy meter dedicated to UV LED light sources.

UV LED light source is widely used in printing machine and other industries besides printing machine due to its outstanding advantages. If you want to choose an instrument to help you measure the intensity of the LED light source, please call us at +86 13510633052! We will provide you with professional answers.