Application of UV Integrator in Curing Machine Industry

UV curing machine refers to the addition of a photosensitizer that is sensitive to ultraviolet light on the cured object or in the adhesive. The ultraviolet light source in the curing machine reacts with the photosensitizer in the UV coating. This machine is used to dry and solidify materials or solids instantly. The core part of the curing machine is a UV lamp with a peak wavelength of 365nm. If you want better curing effect, it is recommended to use a metal halide lamp with a peak wavelength of 380nm. This lamp is mainly used for UV inks that are difficult to cure or have thick coatings.

I. Characteristics of UV curing machine

UV coating equipment, also known as UV curing machine, is widely used in industry. For example, cabinets, doors and windows, bathrooms, nail art, jewelry, production lines and other industries. Since UV curing requires the use of an ultraviolet light source, the light source will decay with time, so it is usually detected by a UV integrator . So what are the characteristics of UV curing?

It can dry instantly and shorten the coating time.

Multi-sided curing can be completed at one time and the curing angle can be adjusted, which can meet multi-specification cured products.

The curing machine usually uses high-pressure mercury lamp or LED lamp, which is clean, convenient and hygienic.

Improve the work efficiency to make the surface of the solidified object smoother and smoother.

II. Maintenance of UV lamps

The service life of ordinary UV-cured lamps is 1200 hours. When the lamp reaches the service life, it should be replaced in time. In the later stage of the lamp use, the UV integrator should be used to periodically detect the energy of the UV lamp.

During the period of use, the UV lamp reflector surface should be cleaned with alcohol or other cleaning materials every one to two weeks. Then rotate the UV lamp tube 180 degrees and replace it when the reflector of the lampshade loses its mirror effect.

Choose a reasonable curing speed, otherwise there will be defective products.

Pay attention to the use time of the UV lamp in time. As the use time of the UV lamp becomes longer, the UV energy will decay. Use UV integrator to check its energy value at any time. Adjust the curing speed in time.

III. Use UV integrator to detect ultraviolet light source

UV curing lamps are generally divided into mercury lamp, LED lamp, metal halogen lamp and rare gas lamps. So when we choose UV integrator, we have to choose according to our curing light. UV integrators are mainly divided into LED curing UV integrators and mercury lamp curing UV integrators.

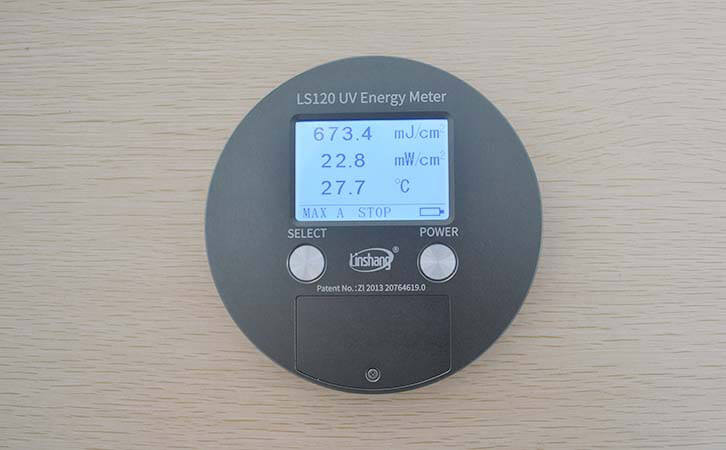

Linshang Technology has invented 4 UV integrators which are mainly divided into mercury lamps and LED lamps. For example, the LS120 UV integrator can be used not only for the UV energy detection of mercury lamps but also for the metal halogen lamps and rare gas lamps. Linshang LS128UV integrator is the first UV integrator in the world for testing LED light sources. Its spectral response range is 340nm-420nm, which can test UV LED lamps in various bands such as 365nm, 385nm, 395nm. This UV integrator has created various firsts:

The first professional UV integrator for UV LED light source testing.

The first wide-range UV integrator with a range of 40W / cm2

The first UV integrator of wide spectrum (340nm-420nm)

The first UV integrator that measures temperature and power simultaneously and can display the process curve

The Linshang UV integrator has a powerful intelligent statistical function and the instrument has a USB interface to connect with computer software. Read the detailed record data, you can print a test report. Makes measurement very convenient.